Bike designed with artificial intelligence breaks world speed records

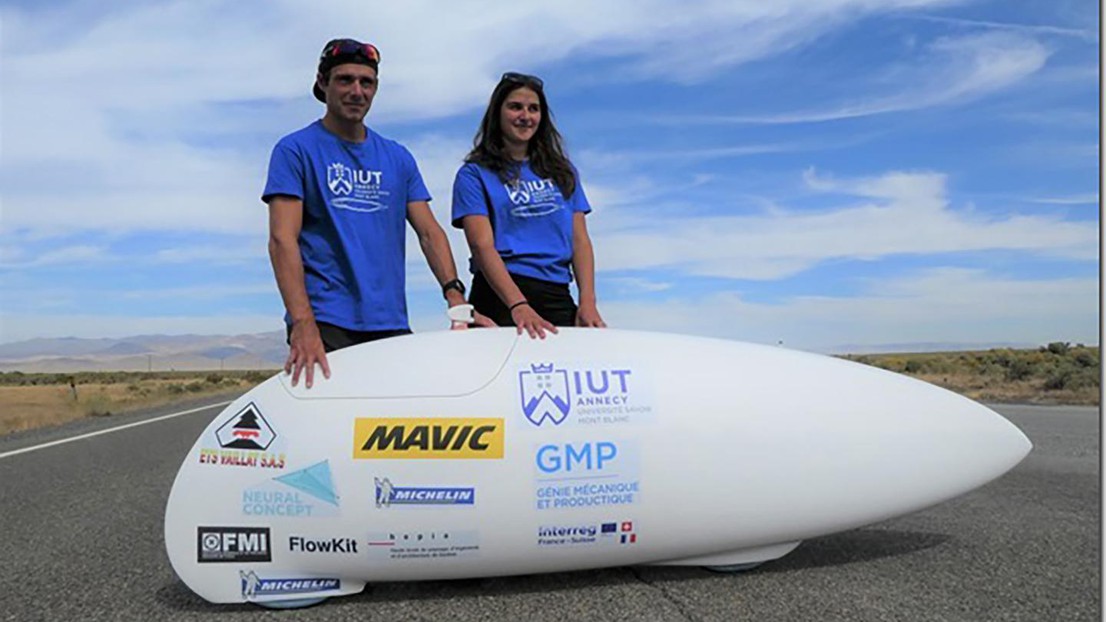

Pilots Fabian Canal and Ilona Peltier © 2019 IUT Annecy

An aerodynamic bike that was designed using software from Neural Concept, a spin-off from the Computer Vision Laboratory (CVLab) in the EPFL School of Computer and Communication Sciences, has broken two world records for cycling speed.

On September 13th, pilot Ilona Peltier bicycled down a 200-meter track at 126.5 kilometers per hour, setting a new world record for women’s cycling speed across all categories. The previous day, her teammate Fabian Canal set a new men’s university world record with 136.7 km/h. The speeds were recorded at the 2019 edition of the World Human Powered Speed Challenge (WHPSC) in Nevada, USA, in which teams of university students take advantage of the flat desert roads to compete for the title of fastest human-powered vehicle.

Peltier and Canal competed as part of the IUT Annecy team, led by Guillaume de France, and both rode a bike designed using a software application developed by CVLab spin-off Neural Concept. The pod-like vehicle, which houses two wheels and is pedaled by a reclining pilot, can travel at speeds faster than many motor-driven vehicles thanks to an optimized, aerodynamic shape proposed by Neural Concept’s artificial intelligence (AI)-driven computer program.

“For us, it was a great opportunity to showcase our technology and do a trial design of a product,” says Neural Concept Director of Operations Thomas von Tschammer.

This is the second time the bike, dubbed Altaïr, has been used in the WHPSC competition. According to von Tschammer, the record-breaking performance this year was down to pilot practice and a couple of aerodynamic tweaks to the bike’s shape.

Speed and optimization

Using a form of AI called deep learning, the Neural Concept Shape software takes a set of constraints – like pilot height, width, and weight in the case of Altaïr – and uses these data to perform aerodynamic simulations. The software’s algorithm “learns” from the data to propose the best designs within the constraints.

Von Tschammer says that Neural Concept’s technology allows engineers to cut down on both the time and the guesswork involved in product design and optimization.

“In industry today, many design processes use trial-and-error-based simulation software that can take several hours. With our deep learning technology, our software can perform aerodynamic simulations within a few milliseconds.”

With the impressive use case of the WHPSC records under their belts, the Neural Concept team now hopes to pursue industry interest in their technology. While it is particularly useful for the aeronautics, automotive and thermal modelling industries, it could be applied to any industry where intensive numerical simulations are performed.

“The big advantage of this technology is that it can speed up simulation processes, allowing companies to increase efficiency and decrease costs, in addition to optimization,” von Tschammer says.