Using viscous metals in micro fibers

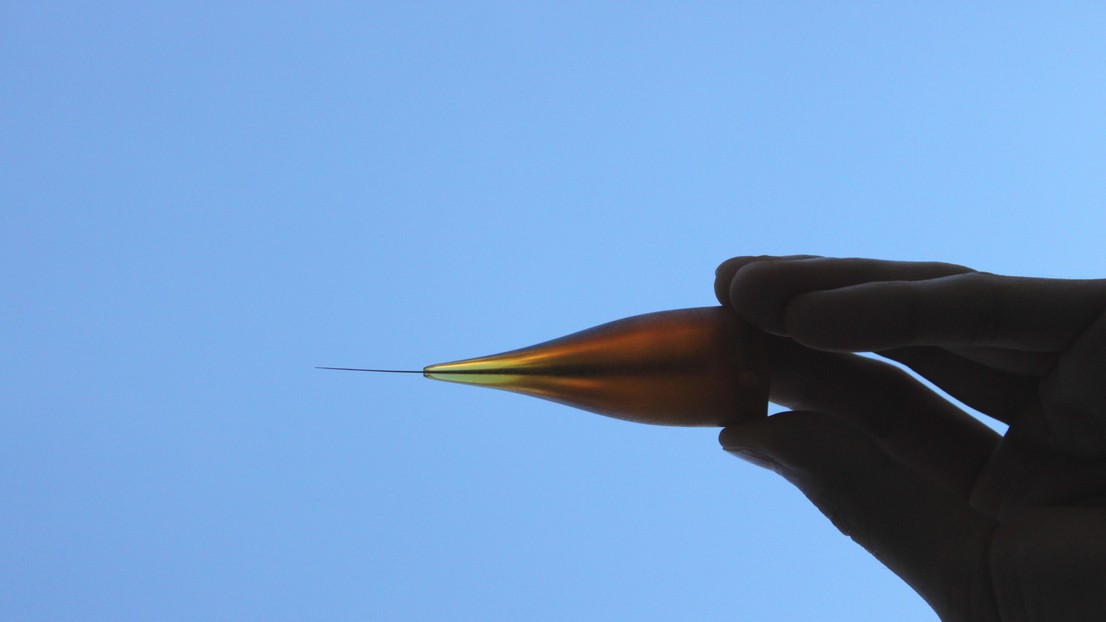

© Wei Yan/2020 EPFL

EPFL scientists have developed the first micro-structured fibers with a viscous metal inside – a perfect example of what cross-disciplinary teamwork can achieve.

Platinum, copper, nickel and phosphorous – those are the components of an amorphous metal alloy with excellent mechanical properties. The alloy is also very corrosion-resistant and attract much interest in watchmaking and micromechanics. Now three scientists from EPFL’s Laboratory of Photonic Materials and Fiber Devices (FIMAP) – PhD student Inès Richard, postdoc Wei Yan and Professor Fabien Sorin – have given it a new purpose: they are using it to make electrodes for plastic fibers. Their paper, which was co-authored by Professor Jörg Löffler from ETH Zurich, has been published in Nature Nanotechnology.

A thin electrical conductor

“Our metallic glass is part of a new category of metals with an amorphous structure,” says Richard. “When the alloy is heated to a certain temperature, it first turns viscous and then becomes crystalline and solid." The advantage is that while the alloy is in a viscous state, it can be stretched into a nanometric-sized, uniform shape that runs the length of the fiber. That’s a step up from the crystalline metals that are normally used – they’re stretched while in a liquid state, which means they can break into droplets if their diameter gets too small.

"Thanks to this alloy and our work with Professor Vasiliki Tileli, who provided further insight into how the process works, we were able to create a very thin, electrically conductive fiber,” says Professor Sorin. “It's just 40 nanometers thick – that’s about 50 times smaller than a standard electrode fiber."

Making rats walk

Because the alloy is viscous, it can be combined with another liquid during the production process without the two mixing. "We added liquid selenium, which can detect light,” says Yan. “The alloy is highly conductive, and because thanks to the high quality of the interface between both materials, it also enhanced the fiber's performance and sensitivity."

"We also worked with Professors Stéphanie Lacour and Grégoire Courtine to test our metallic glass fibers on rats," says Richard. Lacour helped develop a method for integrating the electrodes into chronic implants. Then Courtine's lab tested the implants' functionalities on rats. His researchers sent electrical impulses directly into the rats' brains, causing them to move, and recorded the signals from their neurons. The metallic glass fibers developed at EPFL are designed for use in biomedical devices and electronics.

Swiss CCMX Materials Challenge funding scheme

Swiss National Science Foundation (grant no. 200021_146871)

European Research Council (ERC Starting Grant 679211 ‘FLOWTONICS’)

PREcision Additive Manufacturing of Precious metals Alloys (PREAMPA) project of the ETH domain

ETH research grant (ETH-47 17-1)

European Research Council (ERC-2015-CoG HOW2WALKAGAIN 682999)

European Union’s Horizon 2020 research and innovation programme under the Marie Skłodowska-Curie grant agreement no. 665667

Bertarelli Foundation

DOI: 10.1038/s41565-020-0747-9