The world's first formic acid-based fuel cell

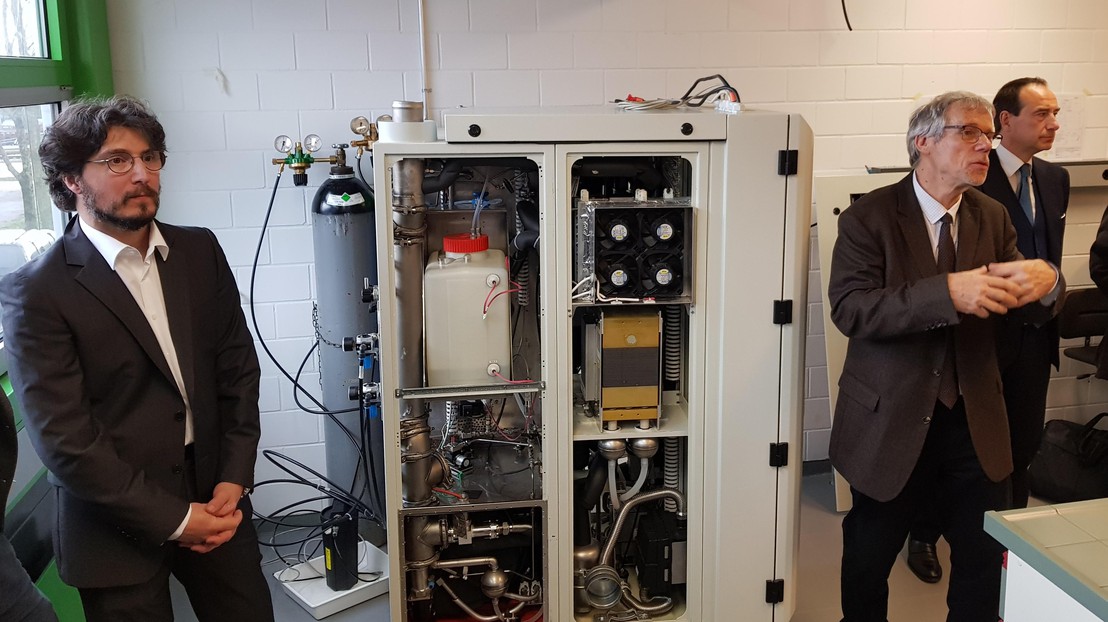

Nordhal Autissier, Gabor Laurenczy and Luca del Fabbro (l. to r.) unveiled the machine on March 19, 2018. © E. Barraud / EPFL

Scientists at EPFL and GRT Group have built the world’s first integrated power supply unit that can produce electricity from formic acid, using a fuel cell in an energy-efficient, safe, cost-effective, and sustainable way.

When it comes to renewable energy storage solutions, hydrogen is one of the most promising energy carriers. Using hydrogen to produce heat or electricity produces no carbon or particle emissions, meaning that it has no negative environmental impact. The problem is that hydrogen has a very low energy content by volume. This makes it very difficult to store and transport in its natural form (gas).

The alternative solution is to use a hydrogen carrier such as formic acid, which is the simplest combination of hydrogen and CO2. One liter of formic acid can carry 590 liters of hydrogen. This is the basis for the project carried out by GRT Group, a company that focuses on energy transition with energy-storage development solutions, and Professor Gabor Laurenczy’s research group at EPFL, who have developed a new, integrated formic acid-hydrogen fuel cell device.

Easy to store and transport

Formic acid is liquid at normal conditions, easy to store, transport, and handle, and is produced from sustainable sources in hundreds of thousands of tons globally: it is already used widely in agriculture, and the leather, rubber, chemical, and pharmaceutical industries.

The device used to extract the hydrogen from formic acid consists of two main parts, a hydrogen reformer (HYFORM) and a proton-exchange membrane fuel cell (PEMFC). The reformer uses a ruthenium-based catalyst to extract hydrogen, although the scientists are currently developing catalysts based on even cheaper materials.

This unit can produce 7000 kWh yearly, and its nominal power is 800 Watts – roughly the equivalent of 200 smartphones being recharged simultaneously. Its electrical efficiency is currently up to 45%. As long as the formic acid used is produced sustainably, the fuel cell is completely environmentally friendly and allows long-term storage of renewable energy. It is quiet, emits clean gas, has zero carbon dioxide balance, and produces neither particles nor nitrogen oxides.

At the same time, the HYFORM-PEMFC is low-maintenance, needing no sulfur treatment, and features stable and long-term catalyst performance. Its technology is scalable, so it can be used in both households and industrial settings. Since it only needs to be fueled with formic acid, the system does not require connection to power grids, which makes it ideal for remote or inaccessible areas.

“The chemical transformation of CO2, a greenhouse gas, into useful products becomes increasingly important as its atmosphere levels continue to rise because of human activity,” says Gabor Laurenczy. “For this reason, producing formic acid in a sustainable way – using CO2 as a hydrogen-energy vector – is very important. Worldwide demand for formic acid is growing, especially in the context of renewable energy. Hydrogen carriers, and their production from CO2, either through hydrogenation or from bio-waste or biomass, are considerably more sustainable than existing routes.”

The HYFORM-PEMFC is the result of a project co-financed by the Swiss Federal Office of Energy and GRT Group.

SNSF

GRT Group