The school with the largest solar facade in the world

© 2017 EPFL Pilippe Vollichard

The Copenhagen International School’s new building is covered by 12,000 colored solar panels based on a technology developed at EPFL. It is one of the largest building-integrated solar power plants in Denmark.

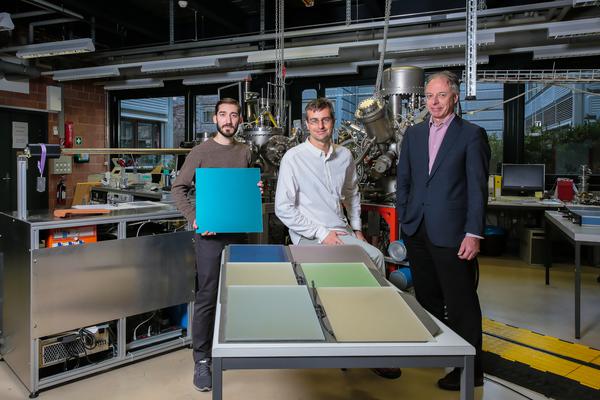

The 12,000 colored solar panels really make the Copenhagen International School’s new building stand out. They completely cover the building and will provide it with 300 MWh of electricity per year, meeting over half of the school’s energy needs. The panels are a distinctive sea green, yet no pigments were used to make them. The color comes from a process of light interference developed over a number of years in EPFL labs.

Light interference is one way of producing color. It’s a similar effect to that seen in soap bubbles, on the wings of some butterflies and in a layer of oil on the surface of water: “The iris effect creates a colorful rainbow on a very thin layer. We used the same principle and adapted for glass,” said Jean-Louis Scartezzini, the head of the Solar Energy and Building Physics Laboratory (LESO-PB).

This sounds easy on paper. In reality, controlling the light reflected by the solar panels so that they produce only one color without reducing energy efficiency was a real challenge.

12 years of research

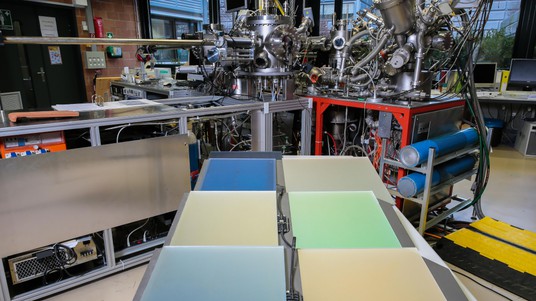

The researchers’ aim was to be able to define the color of their solar panels – such as brick red, royal blue, golden yellow or sea green – by ensuring that only certain wavelengths are reflected. This required a series of digital simulations and a special manufacturing process, and it took 12 years to get from the first sample to the first colored solar facade. The researchers developed special filters, which they applied to the glass panels in nanometric layers. The filter design determines which wavelengths of light will be reflected as visible color. The rest of the sunlight is absorbed by the solar panel and converted into energy.

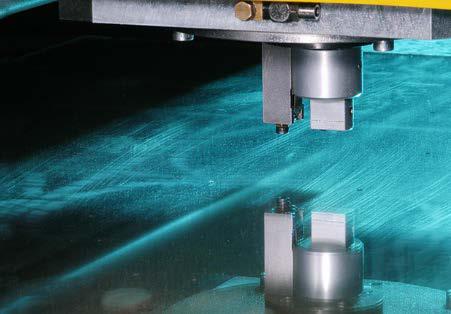

Andreas Schüler, who has led this project from the start, notes the challenge in achieving stable colors: “We have a free hand in developing our filters – we can achieve specific refraction indexes by combining different oxides. We work layer by layer, using between three and 13 layers in any given filter design. We have to find the right composition and thickness of layers so that they reflect the desired wavelengths while at the same time meeting the solar power requirements.”

By tinting the solar and thermal panels, the researchers are able to hide their unsightly components. The panels thus become architectural features in their own right.

A spin-off, patents and projects

This technology is covered by two patents, and the colored solar panels are now being mass produced. They are made in one large size – 3 x 6 meters, 4 mm thick – and then cut to the architects’ specs.

“Making evenly colored samples was difficult,” notes Schüler. “A discrepancy of only 5 nanometers would affect the color. We thus had to achieve nanometric  precision at a scale of a square meter.” Another problem was the size of the machines, which have to be at least 100 meters long in order to apply the layers of the filter. “We looked for partners in Europe, but companies here weren’t willing to take the chance. It turned out that Emirates Glass had the factory, the machines and the desire to take on this project,” said Nicolas Jolissaint, an engineer at SwissINSO, an EPFL spin-off. The two companies set up a joint venture, Emirates Insolaire, which provided the colored panels to cover the Copenhagen International School.

precision at a scale of a square meter.” Another problem was the size of the machines, which have to be at least 100 meters long in order to apply the layers of the filter. “We looked for partners in Europe, but companies here weren’t willing to take the chance. It turned out that Emirates Glass had the factory, the machines and the desire to take on this project,” said Nicolas Jolissaint, an engineer at SwissINSO, an EPFL spin-off. The two companies set up a joint venture, Emirates Insolaire, which provided the colored panels to cover the Copenhagen International School.

This building was described by Mother Nature Network as one of “5 solar-powered buildings that will forever change architecture.”

CIS Nordhavn is the Copenhagen International School's new campus. The campus building was designed by C.F. Møller Architects and sits in Nordhavn, a new district in Copenhagen.