Scientists solve a long-standing mystery about wear

© Ramin Aghababaei 2016

It generates particulate-matter air pollution and degrades mechanical parts. Adhesive wear a major, yet poorly understood problem. Using simulations, researchers from EPFL offer new insights into what happens when seemingly smooth surfaces rub against each other.

Adhesive wear can cause machine failure, particulate-matter air pollution, and many other societal woes. Yet despite its impact on the economy and health, the physics behind wear remains poorly understood. For the first time, an EPFL-led study has reproduced the production of debris particles by adhesive wear in a computer simulation based on the atomic interactions between two surfaces. Their findings, published in the journal Nature Communications on June 6, could pave the way towards diminishing energy and material losses.

Unless you are a mechanical engineer, wear is unlikely to be on your radar. So who should care about wear, and why? According to Ramin Aghababaei, a researcher at the Computational Solid Mechanics Laboratory, and the lead author of the study, we all should. “A team of Swiss scientists recently estimated that 20% of noxious particulate matter in the air comes from brake pads in our vehicles and road surface wear. And any machine with moving parts is subject to adhesive wear, which ultimately shortens its lifespan,” he says. And in the kitchen, when pie dough gets stuck to your dough roller, you are witnessing adhesive wear, just at a much larger scale.

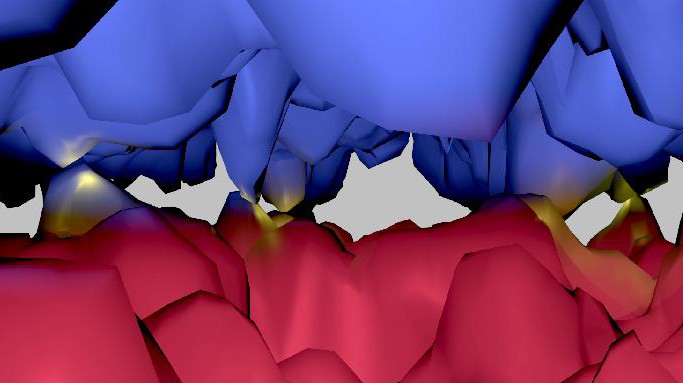

Regardless of scale, the process is always the same: two surfaces – the gears of a watch, brake pads against their disks, an artificial joint against its socket – rub against each other. Short-ranged atomic forces acting between the surfaces, known as van der Waals forces, locally stick the surfaces to each other. If the stickiness is strong enough, small fragments of one of the surface can be peeled off, eventually leading to the formation of tiny debris particles.

Experimental researchers have developed countless models of the adhesive wear process and debris formation. But in computational simulations based on the inter-atomic forces that act between the two surfaces, the surfaces instead become smoother as they rub against each other, and no sustained debris is produced. The challenge was to reconcile the simulations and reality.

“Our simulation is the first to reproduce the generation of debris particles through adhesive wear, we are very excited about the outcome,” says Aghababaei. Though the contact surfaces may appear to be perfectly smooth, at the microscopic level, they are covered in microscopic bumps. “What we found is that debris is only formed when the contact between the microscopic asperities on the material surfaces exceed a critical length. When the contact is smaller, the materials instead become smoother as they rub against each other,” he says.

One reason their discovery has eluded researchers for so long is the sheer size of the computer simulation it would take to capture asperities exceeding the critical length in a atomic scale simulation. To make their discovery, the researchers had to run their simulation considering a model material with properties such that the simulation could capture the critical length scale for debris formation. “We hope that our finding will spark some new activity in the experimental community, and in the industries for which wear is important,” concludes Jean-François Molinari, the study’s senior author.

This research is a collaboration between the Computational Solid Mechanics Laboratory at EPFL and Cornell University (Professor Derek Warner), funded by an ERC Starting Grant.