Saving educational robots from the trash

Robotics master's student Alexandre Viegas. 2025 EPFL/Alexandre Viegas CC BY SA

EPFL master’s student Alexandre Viegas has teamed up with repair website iFixit to develop rankings and repair guides for educational robots. His work aims to help students build new skills while promoting sustainable technology use.

It’s a common frustration of the modern age: an expensive electronic device stops working but repairing it seems impossible. Even if you manage to open the device’s casing and identify the problem, how can you repair it or install replacement parts correctly? In the end, it’s usually easier to buy a new device – and add to the increasing global burden of electronic waste, which is expected to reach 82 billion kilograms by 2030.

“Consumers often prefer to replace their devices rather than repair them due to lack of knowledge, limited access to repair options, or even just an unrepairable device design,” says EPFL robotics master’s student Alexandre Viegas. “This creates a need for resources like minerals, water, and energy, while generating waste that could be avoided by providing better education on the subject. This is where educational robotics can be a powerful tool.”

As part of his semester project, Viegas worked with Cyril Monette and Francesco Mondada of the Mobile Robotic Systems (MOBOTS) Lab in EPFL’s School of Engineering, in collaboration with US-based repair website iFixit to develop a repairability index to support sustainability-minded robot purchases in education.

“This project brings educational robots into the repair field – an area often overlooked in consumer electronics,” Viegas says. “We hope that publishing repair guides and scoring these educational robots will encourage teachers to bring these topics into the classroom, and manufacturers to prioritize repairability in their product design.”

A win-win for students and sustainability

Even as a child, Viegas enjoyed tinkering with his toys. “As soon as a device of mine broke, I always tried to fix it myself by looking up guides and parts online. These activities actually encouraged me to become an engineer, specifically in robotics, where I could learn to build and fix anything.”

By developing the first dedicated scoring method for educational robots, this project highlights the importance of repair in robotics. Our efforts contribute not only to building students’ understanding of technology, but also to a more responsible, sustainable, and circular approach to technology use

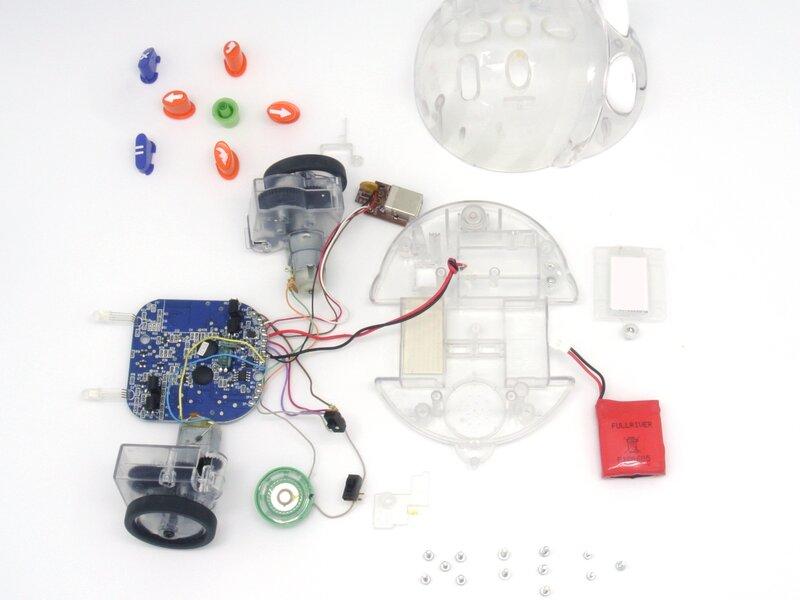

For his EPFL semester project, Viegas focused on nine motorized educational robots commonly used in schools, including the MOBOTS Lab’s own two-wheeled Thymio II. Together with the MOBOTS team and iFixit experts, as well as Mobsya, the non-profit producer of Thymio, he developed a scoring system to rank the robots based on their repairability from the end-user’s point of view. This involved taking apart each robot and applying an adapted version of iFixit’s own product repairability scoring system, which ranks devices based on three criteria: documentation, replacement parts, and design for repair.

In the end, Thymio II topped the repairability ranking with 10/10 thanks to its ease of repair, thorough repair documentation, and accessible replacement parts. In contrast, the globe-like Sphero Bolt+ coding robot scored 0 out of 10, since it couldn’t be opened without being destroyed.

“Thymio’s high rank was not surprising, as this robot was intended to be repairable, but its comparison to the main products available on the market illustrates the importance of integrating repairability into the early stages of robot design,” Viegas says.

As part of the project, Viegas and his colleagues also published repair guides for three robots – Thymio, the Blue-bot and the Root robot – which are now freely available on the iFixit website. Although he is now focused on his applications engineering internship at Sensirion Connect, where he is working on smart devices for detecting methane emissions and pollution, Viegas says he still plans to contribute to the repair guides in his spare time. Meanwhile, the MOBOTs team plans to turn the guides into full-fledged classroom activities aimed at explaining why repair is important for reducing environmental impacts, while giving students hands-on repair experience.

“By developing the first dedicated scoring method for educational robots, this project highlights the importance of repair in robotics. Our efforts contribute not only to building students’ understanding of technology, but also to a more responsible, sustainable, and circular approach to technology use,” Viegas says.