Robots that adapt to their environment – and you

The Mori3 origami robot © Titouan Veuillet

On the occasion of the 10th anniversary of the Reconfigurable Robotics Lab, a demonstration of daily-use devices showcased director Jamie Paik’s vision – now a reality – for a new category of versatile robots.

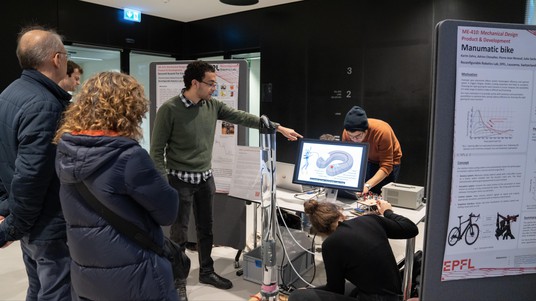

From self-fastening shoes to an emergency airbag for divers, and from a drink-pouring third arm to an automatic bike gear-shift system, the robotic devices demonstrated at the Reconfigurable Robotics Lab (RRL)’s campus celebration on December 9th addressed an impressively broad range of needs. Even more impressive is the fact that many were developed in Paik’s Mechanical Product Design and Development (ME-410) course, which she says is unique at EPFL for its focus on product development.

“In this course, students are graded on a working prototype of a wearable robot that they have created for daily use. Each prototype must be an actual robot that moves and modulates its activity in response to sensory information – not just another phone app!” Paik laughs, adding that every step in the prototyping process is relevant to industry.

“Students must be able to address a problem or need as an engineer, and to quantify their results. If you can’t explain to the public why your device deserves funding, then someone else will get that funding.”

The RRL in the School of Engineering hosts an annual showcase of devices developed in ME-410, but this year, which marks the lab’s tenth anniversary, a special celebration also included demonstrations of other robots developed in the lab over the past decade.

Making ‘customizable hardware’ a reality

Paik’s vision upon launching the RRL was not just to design and build reconfigurable robots, but to initiate a paradigm shift in the relationship of robotic devices to their users.

“Everything on a smartphone, from the display wallpaper to the alarm clock, can be adapted to its user thanks to the customizability of its software. With reconfigurable robots, the hope is to have customizable hardware: devices that can respond to changing environments and needs,” Paik explains.

“When I started my lab, I wanted to develop robots for daily use that would increase our freedom by expanding our options in different situations. And after 10 years, I am excited to say that this is not just the future – it is a reality.”

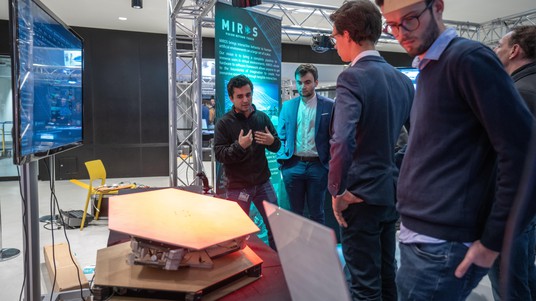

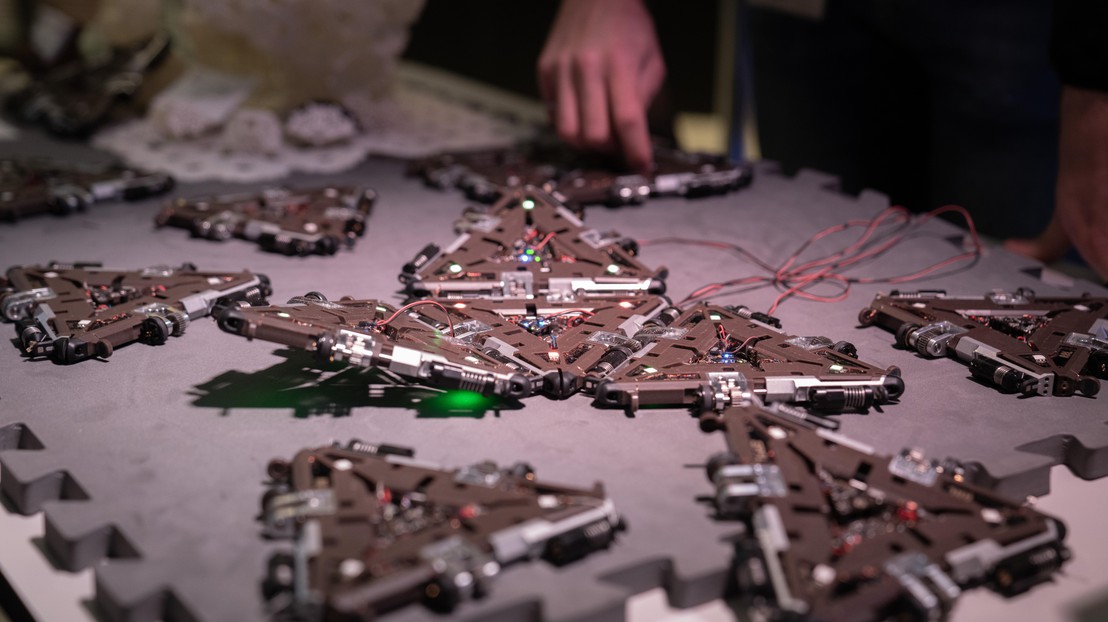

Indeed, each of the featured robots clearly demonstrated such responsiveness, including the origami robots that have become some of Paik’s signature devices. Several modules of the Mori3, for example, can be connected to form an independent robot that can change shape to adapt to new environments. A force-feedback surface dubbed Miros (Multi-scale Interactive Robotic Surface), which can respond to different parts of the human body to create an interactive environment, has even recently been selected for presentation at the 2023 edition of CES – the influential global trade show of the Consumer Technology Association. Miros follows a device of RRL spinoff Foldaway Haptics that was installed on the Mercedes-Benz Vision Avtr concept car at CES 2020.

Valorizing – not replacing – human work

When it comes to research plans for the RRL’s next decade, two areas interest Paik in particular. On a smaller scale, she is fascinated by the human brain; specifically, using robotic devices to transfer physical information about touch to a digital platform. The ability to create an immersive experience that integrates real tactile sensations – the hardness, shape, and texture of a surface, for example – could be extremely useful for helping to train surgeons or astronauts to deal with new or unexpected environments.

And speaking of space, Paik also sees important extraterrestrial uses for reconfigurable robots in the very near future.

“Space is one of the most difficult environments to have automation in, because it’s so expensive. But you have to be prepared for the unknown. While a rover’s wheels can get stuck and cause the robot to flip over, a reconfigurable robot can adapt, and come up with versatile solutions to address an unexpected problem on the spot.”

She emphasizes, however, that the goal will never be to use robots to replace humans.

“What we want to do in the RRL is to abstract the human ability to perform specific tasks, and to make that work more versatile – but not replaceable. We want to valorize human work on such tasks using technology.”