Reusing electric pylons to design the roof of a train station

Six high-voltage lines are due to be taken down in Valais canton. © Swissgrid

For his Master’s project, Joseph Desruelle devised a plan to reuse steel bars from dismantled electricity pylons to make a new roof for the Lausanne train station. This approach is still theoretical, but reusing materials in this way could one day become commonplace.

For his Master’s project in civil engineering, Joseph Desruelle came up with a project to count and classify thousands of steel bars from dismantled electric pylons, and to use their mechanical properties to design a new train-station roof. Desruelle’s project was supervised by Corentin Fivet at EPFL’s Structural Xploration Lab (SXL) – based at the smart living lab in Fribourg – and Aurelio Muttoni at EPFL’s Structural Concrete Laboratory (iBeton), and his oral defense took place on 22 March.

The approach Desruelle used forms part of a new strand of research in civil engineering: reusing structural elements in their raw form (steel bars and systems, wooden beams etc.) at the end of their service lives, instead of recycling them or scrapping them. Reusing materials in this way reduces the embodied carbon footprint of new buildings, since 71% of their greenhouse gas emissions result from the extraction and production of materials and the construction phase. The approach also reduces the amount of waste produced by the construction sector, which accounts for around a third of all waste produced in Europe. Lastly, reusing materials has the advantage of preserving finite natural resources.

Despite all those benefits, little research has been done in this field, and there have been few practical applications to demonstrate its value. That’s why Desruelle started his study with a theoretical analysis that aims to facilitate this approach. He developed an optimization algorithm allowing a structure – such as a bridge or building – to be designed using any type of reused structural elements. The engineer enters the number of elements available for reuse and their size, mass, geometry and mechanical properties, and the algorithm proposes an optimal design that minimizes the quantity of materials required, without creating additional waste but leaving room for creativity. In his theoretical study, Desruelle drew on work being done by Jan Brütting, a doctoral student at SXL.

Case study

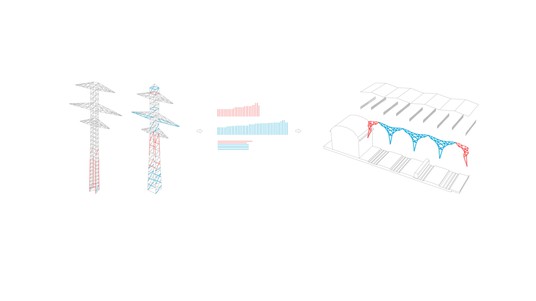

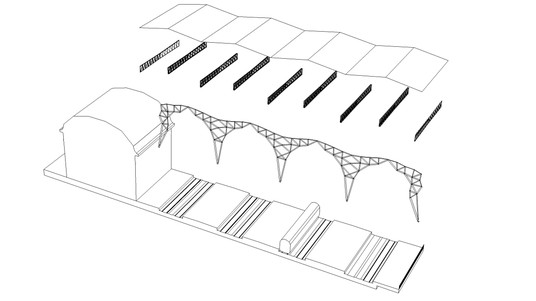

In the second part of his project, Desruelle tested his process in a case study inspired by the dismantling of six high-voltage power lines in Valais canton. This will potentially create 18,000 steel bars per line, of which just over 80% will be reusable. Taking these components, Desruelle used his algorithm to redesign a 200-meter-long roof structure covering the tracks and platforms at the Lausanne train station. He set himself two main constraints: he had to avoid cutting any steel bars and he had to reuse existing connections.

By opting for a modular design, Desruelle was also able to ensure that his roof reused modules of the pylons, without taking them apart. “This way of reusing materials has the benefit of saving labor, as the components simply need to be carried from one place to another,” he said. In the end, the project would use only 20% of the materials from the high-voltage lines, and would reduce embodied carbon by 80% compared with building an identical roof using brand new materials.

It so happens that the Swiss Federal Railways is planning to make changes to the Lausanne train station’s historical canopy as part of the project to expand the station. However, Desruelle makes clear that, since the roof is listed, there are no plans to replace it or convert it. According to the drawings he has received from the Swiss Federal Railways, the canopy will simply be extended to cover the longer platforms. However, Desruelle’s project could be used in other applications, such as for a manufacturing plant, a sports center or even a bridge.

Alternative reality

“We are still in the realm of alternative reality,” says Corentin Fivet, who jointly supervised Desruelle’s Master’s project. “There are several economic and civil-liability issues to be resolved. However, from an engineering point of view, we wanted to show that, using our tools, it will soon be possible to reuse structural elements in a highly efficient way to build new structures. The European Union is investing a lot of money in this field of research, which it sees as a way of creating jobs and boosting local economies. I am optimistic that this approach will soon become the obvious choice.”

Desruelle adds: “The whole point is to change the way we think about civil engineering – where the current paradigm could be summed up as build it, used it, tear it down and throw it away – and move towards a circular-economy approach.” Does that mean that architects will have to take into account available materials at the design stage? Fivet, who is himself an architect and engineer, is convinced that they will, and he sees a new challenge therein: “Architects will use their creativity to find the best reusable materials as the basis for the structure and then devise how to use them most effectively.” This method might have been of interest to Jean Tinguely, who was born in Fribourg and whose museum is located just a few miles away from the laboratory where this research was done.

This Master’s project was carried out with the assistance of Swissgrid.

Joseph Desruelle, STRUCTURAL FORM-FINDING FROM RECLAIMED BAR ELEMENTS, Master Thesis, Supervisors: Prof. Aurelio Muttoni, Prof. Corentin Fivet, Civil Engineering, EPFL, 2 March 2018. (Available online in June 2018)