Precise layering in catalysts for building sustainable chemicals

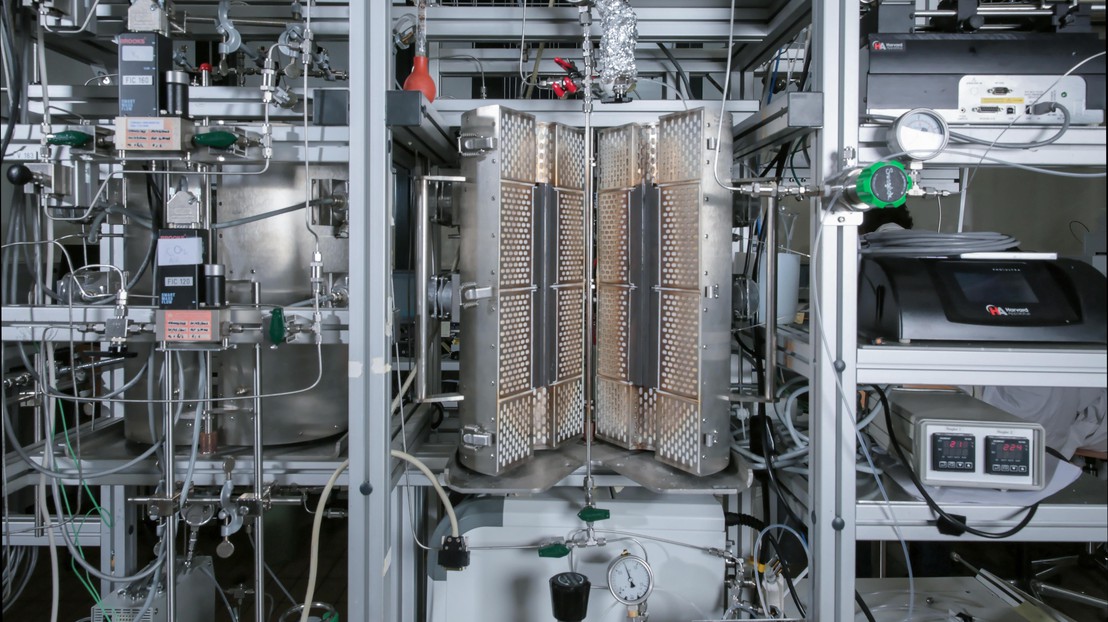

The reaction setup used to transform carbon dioxide with precisely layered catalysts. 2024 EPFL / Alain Herzog CC-BY-SA 4.0

EPFL chemical engineers have developed a way to build metal clusters – with near atomic precision – in a method that has the potential to improve catalysts and accelerate chemical reactions including turning carbon dioxide into high value chemicals like methanol.

Motivated to turn greenhouse gases like carbon dioxide into high value chemicals like methanol, EPFL chemical engineers have developed a new method to make catalysts. Catalysts are major tools in the chemical industry and are largely made to make petrochemicals. In this method, they have developed a way to build – with near atomic precision – metal clusters on solid supports that have the potential to improve catalytic activity. The results are published in Nature Catalysis.

“You want to produce as much product per time per catalysts as possible, and we’ve found that when a catalyst is prepared with near atomic precision, you get a more active material,” says Jeremy Luterbacher, professor at EPFL’s Laboratory of Sustainable and Catalytic Processing. “This technique is particularly interesting for difficult reactions like that of carbon dioxide with hydrogen gas for producing renewable methanol.”

A bit about catalysts

Though they are ubiquitous in industry, we most commonly interact with solid catalysts in the tailpipe of our car. There, a catalytic converter takes the exhaust from fuel combustion and helps to reduce the amount of toxic pollutants released into the air. The engine of a car notably produces carbon monoxide (CO), an odorless and colorless toxic gas that, in high concentrations, can cause illness and death if inhaled. Inside the chamber is a catalyst, usually made of small platinum or palladium particles on a cheaper solid. This metal binds air and pollutants like carbon monoxide, and helps them react to produce the less toxic carbon dioxide (CO2) gas into the air.

“A reaction can happen without a catalyst at high temperature. For instance, burning carbon monoxide in a flame makes it possible for the carbon monoxide and oxygen to crash together to form carbon dioxide because they’re hot enough for the collision to be sufficiently powerful,” explains Luterbacher. “With a catalyst, the carbon monoxide and the oxygen are bound to a metal surface and they can react despite colliding at a lower temperature. It’s like they’re ice-skating on the surface of the catalyzer and the surface helps the transformation between the pollutant and the reactant along.”

The catalysts of the future need to be able to turn carbon dioxide, a greenhouse gas that’s the largest source of renewable carbon on our planet, into high value gases like methanol. This process takes place in a chemical reaction referred to as a hydrogenation, a difficult reaction since it can produce many things other than methanol. Making a catalyst that is active enough to transform carbon dioxide fast enough to methanol without making other products is a significant challenge.

Precision layering of the catalyst

To make a solid catalyst, a metal particle is deposited on top of a material with high surface area like a porous powder, to maximize contact with the reactant.

Luterbacher and his team wondered if they could control and speed up reactions by precisely controlling the catalyst composition, notably by choosing just the right amount of material to tune how tightly reactants would bind to the catalyst. They had discovered in previous research that they could deposit islands of metals with near atomic precision on solid supports, a method called liquid-phase atomic layer deposition (ALD), perfect for creating precise catalyst active sites for enabling a reaction.

Indeed, depositing these small islands or clusters of several metals with near atomic precision allowed the EPFL team to hydrogenate carbon dioxide at rates that were more than ten times higher than with a catalyst of the same composition but built without this control. They used magnesium oxide as the support, which usually binds carbon dioxide too tightly to be reactive, and they deposited small zirconia islands, which is a material that usually binds carbon dioxide too lightly. Then, they added copper to bind the hydrogen. When placed together in just the right proportions, they seemed to have the right mix to make a lot of methanol quickly and little of anything else.

“Magnesium oxide is widely recognized as a stable material for CO2 capture, but its strong affinity for CO2 has limited its use as a catalyst support. We turned this limitation into an opportunity by teaming it up with zirconia. Finding the optimal balance for CO2 affinity by combining MgO and ZrO2 with differing properties was only achievable through the powerful tool of liquid-phase atomic layer deposition,” says Seongmin Jin, former postdoctoral researcher at LPDC and lead author of the study.

“If we compare the amount of catalyst material to its copper content, then our catalyzer is more active than even commercial catalysts. Our activity per active site is also superior. It’s worth noting that our activity per weight of catalyst material is still inferior to commercial equivalents because we need to figure out how to make much more of these clusters on the surface. But we’ve shown that it’s possible to achieve very high control even at the atomic level, and this control appears to be very important. This opens the avenues to explore many combinations of metals or possibilities,” concludes Luterbacher.

https://www.nature.com/articles/s41929-024-01236-y