Paper alert - Blade-Coating of High Crystallinity CsFA perovskites!

© 2024, ACS AM&I

PV-Lab is happy to share that our latest paper "Blade-Coating of High Crystallinity Cesium-Formamidinium Perovskite Formulations" has been published in ACS AM&I! This work has been dedicated to the transfer of the optimized Cs0.15FA0.85PbI3 film deposition from a lab-scale process to a more industrially compatible coating method, i.e., blade-coating on the way to scaling up for perovskite solar cells.

PV-Lab is happy to share that our latest paper "Blade-Coating of High Crystallinity Cesium-Formamidinium Perovskite Formulations" has been published in ACS AM&I! A big thanks to all the co-authors Anaël Jaffrès, Mostafa Othman*, Felipe Saenz, Aïcha Hessler-Wyser, Quentin Jeangros, Christophe Ballif and Christian M. Wolff* for the fruitful collaboration!

Highlights from the article;

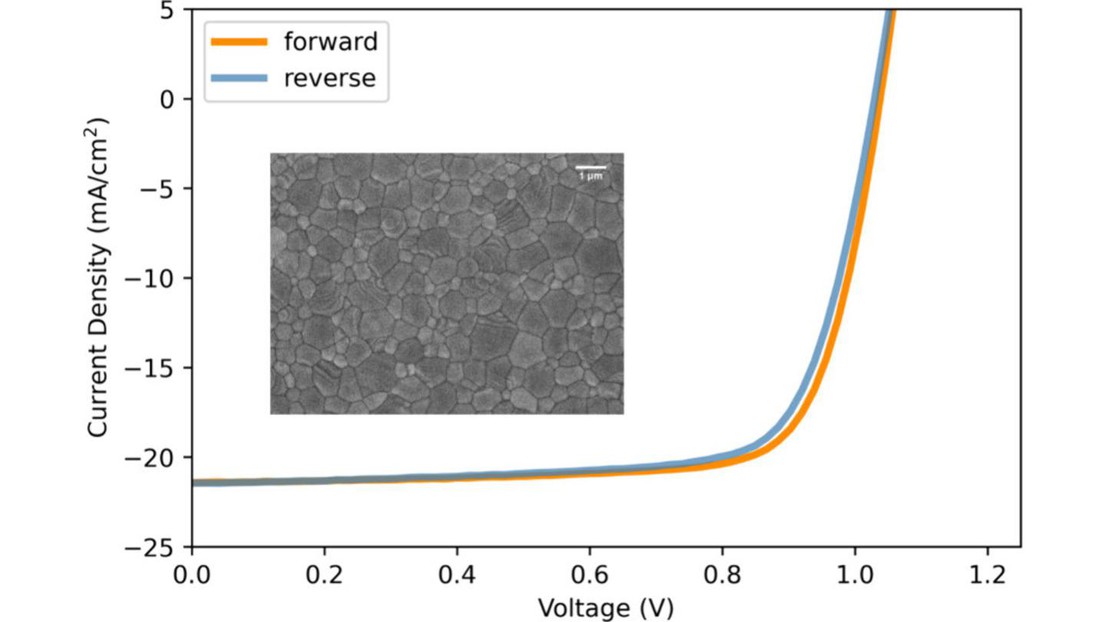

''Up-scalable coating processes need to be developed to manufacture efficient and stable perovskite-based solar modules. In this work, we combine two Lewis base additives (N,N′-dimethylpropyleneurea and thiourea) to fabricate high-quality Cs0.15FA0.85PbI3 perovskite films by blade-coating on large areas. Selected-area electron diffraction patterns reveal a minimization of stacking faults in the α-FAPbI3 phase for this specific cesium-formamidinium composition in both spin-coated and blade-coated perovskite films, demonstrating its scaling potential. The underlying mechanism of the crystallization process and the specific role of thiourea are characterized by Fourier transform infrared spectroscopy and in situ optical absorption, showing clear interaction between thiourea and perovskite precursors and halved film-formation activation energy (from 114 to 49 kJ/mol), which contribute to the obtained specific morphology with the formation of large domain sizes on a short time scale. The blade-coated perovskite solar cells demonstrate a maximum efficiency of approximately 16.9% on an aperture area of 1 cm2.''