Next-gen membranes for carbon capture

iStockPhotos

EPFL chemical engineers have developed a new class of high-performance membranes for carbon capture that greatly exceed current targets.

Congratulations to Emad for his contribution to this work, published in Energy & Environmental Science.

A major greenhouse gas, CO2 produced from burning fossil fuels is still mostly released into the atmosphere, adding to the burden of global warming. One way to cut down on it is through a carbon capture: a chemical technique that removes CO2 out of emissions (“postcombustion”), preventing it from entering the atmosphere. The captured CO2 can then be either recycled or stored away in in gas or liquid form, a process known as sequestration.

Carbon capture can be done using so-called "high-performance membranes", which are polymer filters that can specifically pick out CO2 from a mix of gases, such as those coming out of a factory’s flue. These membranes are environmentally-friendly, they don't generate waste, they can intensify chemical processes, and can be used in a decentralized fashion. In fact, they are now considered as one of the most energy-efficient routes for reducing CO2 emissions.

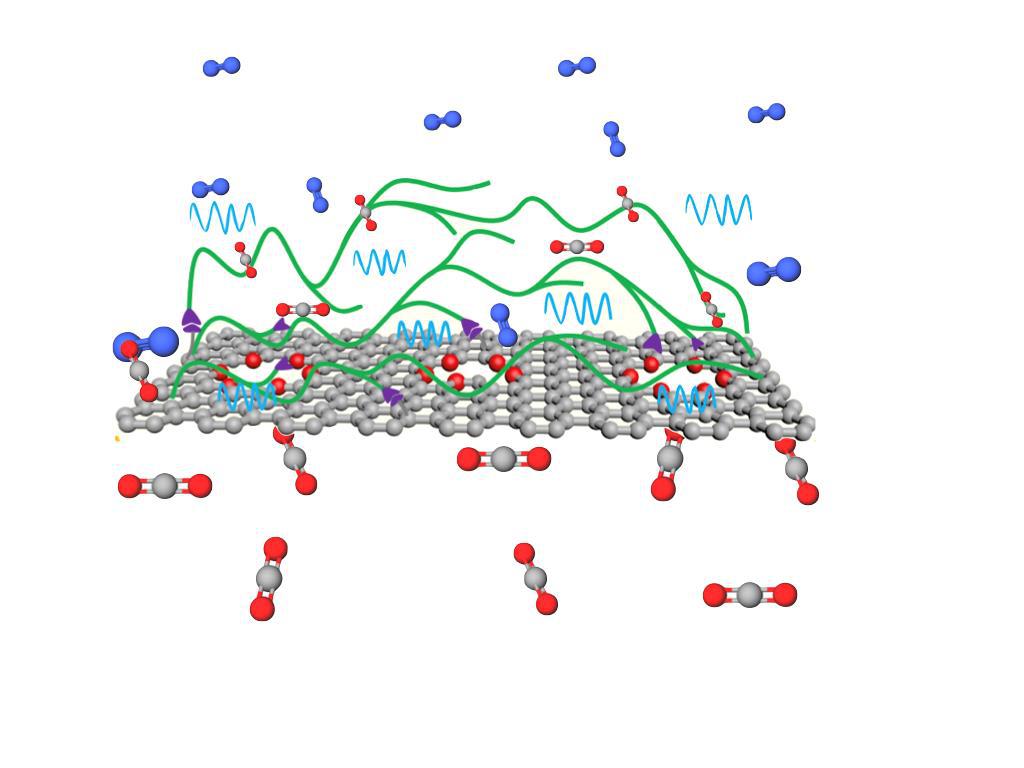

Scientists led by Kumar Varoon Agrawal at EPFL Valais Wallis have now developed a new class of high-performance membranes that exceeds post-combustion capture targets by a significant margin. The membranes are based on single-layer-graphene with a selective layer thinner than 20 nm and are highly tunable in terms of chemistry, meaning that that can pave the way for next-generation high-performance membranes for several critical separations.

Current membranes are required to exceed 1000 gas permeation units (GPUs), and have a “CO2/N2 separation factor” above 20 – a measure of their carbon-capturing specificity. The membranes that the EPFL scientists developed show six-fold higher CO2 permeance at 6,180 GPUs with a separation factor of 22.5. The GPUs shot up to 11,790 when the scientists combined optimized graphene porosity, pore size, and functional groups (the chemical groups that actually react with CO2), while other membranes they made showed separation factors up to 57.2.

CO2-selective polymeric chains anchored on graphene effectively pull CO2 from a flue gas mixture. Credit: KV Agrawal (EPFL)

“Functionalizing CO2-selective polymeric chains on nanoporous graphene allows us to fabricate nanometer-thick yet CO2-selective membranes,” says Agrawal. “This two-dimensional nature of the membrane drastically increases the CO2 permeance, making membranes even more attractive for carbon capture. The concept is highly generic, and a number of high-performance gas separations are possible in this way.”

Other contributors

EPFL Innovation Interdisciplinary Centre for Electron Microscopy (CIME)

EPFL

ETH Board

GAZNAT

Swiss National Science Foundation

Swiss Competence Center for Energy Research – Efficiency in

Industrial Processes (SCCER-EIP)

European Union Horizon 2020 (Marie Skłodowska-Curie grant)

Guangwei He, Shiqi Huang, Luis Francisco Villalobos, Jing Zhao, Mounir Mensi, Emad Oveisi, Mojtaba Rezaei, Kumar Varoon Agrawal. High-permeance polymer-functionalized single-layer graphene membranes that surpass the postcombustion carbon capture target. Energy & Environmental Science 26 July 2019. DOI: 10.1039/c9ee01238a