New article in Composites Part A

© 2025 EPFL

A numerical study of a tow-by-tow curing approach for residual stress mitigation in thick composites

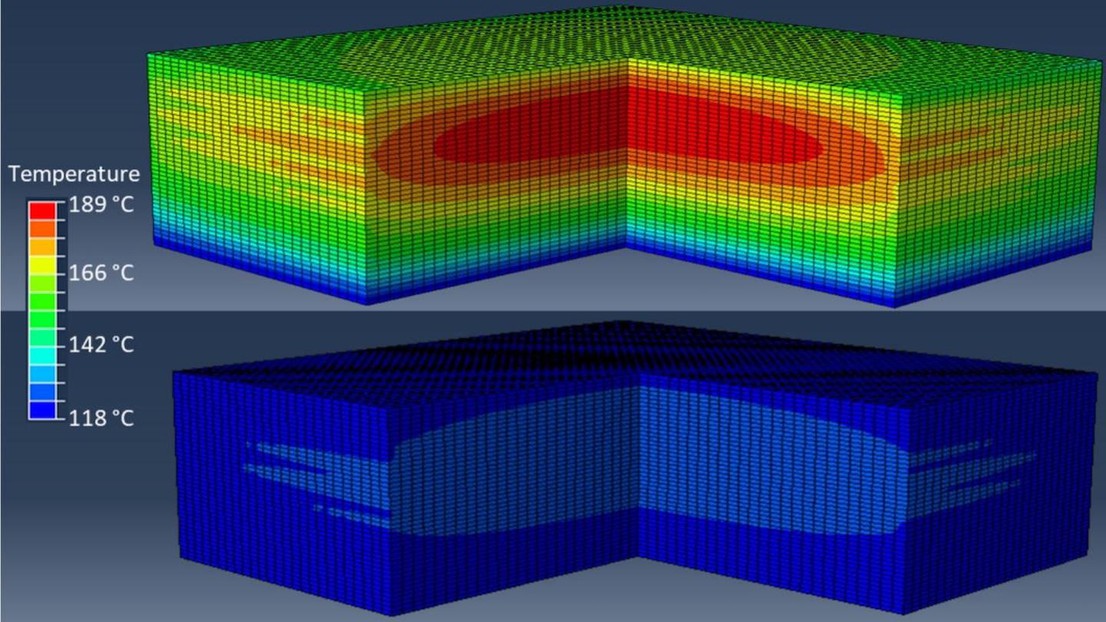

Thick thermosetting composites offer unique opportunities for high-performance applications in several fields such as aerospace, wind energy, piping, pressurised vessels, marine industry, etc. However, realising their full potential requires a deep understanding of material behaviour during processing since cure-induced defects, such as thermal spikes, residual stresses and cure inhomogeneity, can undermine mechanical performance and increase the risk of flawed parts. This study numerically investigates a novel additive manufacturing (AM) process for continuous carbon fibre-reinforced polymers (CFRP), combining partial pre-curing and in-situ curing strategies. By leveraging the properties of partial curing, the investigation aims to mitigate cure-induced defects. The influence of key parameters (pre-cure level, printing speed, heat source size and intensity) is investigated by means of a simulation framework incorporating detailed modelling of material property evolution to mimic the process and predict the distribution of temperature, stress and degree of cure. Results highlight the impact of thermal and cure gradients on residual stress accumulation and show that partially curing the material before and during layup up to 0.67 conversion can reduce the exotherm during final cure by up to 92 %, and lower through-thickness internal stress by up to 65 % after cool-down compared to standard manufacturing. In addition, an optimal selection of printing speed and heat input can enhance processing speed by exploiting an acceptable level of temperature overshoot or defining more aggressive cure cycles. The insight into AM for defect-minimised composite structures can ultimately contribute to the development of more reliable and efficient manufacturing processes.

This work was supported by the Laboratory for Mechanical Systems Engineering, Swiss Federal Laboratories for Materials Science and Technology (Empa), Switzerland, through the Empa Board of Directors