Microcomb-injected pulsed lasers as variable microwave gears

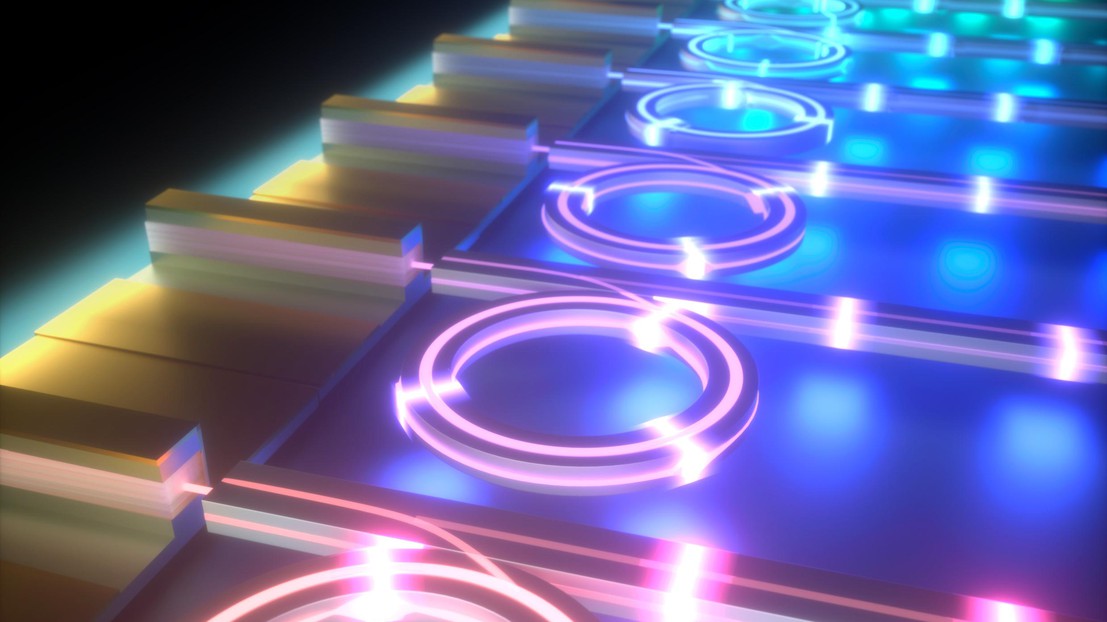

Credit: T. J. Kippenberg (EPFL)

Optical frequency combs can link frequencies in the microwave domain to high-purity laser emissions, yielding unprecedented precision in time-keeping and metrology. Now EPFL scientists and their colleagues have generated variable low-noise microwave signals by building variable microwave gears with two compact optical frequency combs.

Low-noise microwave signals are of critical importance in numerous applications such as high-speed telecommunication and ultrafast data processing. Conventionally, such signals are generated with bulky and delicate microwave oscillators that are not suitable for out-of-door applications. But recently, physicists have been exploring a possible alternative: high-quality microwave generation using optical microresonator frequency combs.

Relying on the high optical frequency and spectral purity of laser fields, optical microresonators can generate low-noise microwaves in a compact and efficient manner. But a microresonator can usually only generate microwaves with very limited frequency tunability. The reason is that the microwave frequency depends on the resonator’s size, which is not itself highly tunable.

Publishing in Science Advances, researchers at Tobias Kippenberg’s lab at EPFL, Trinity College Dublin (TCD), and Dublin City University (DCU) have now developed a novel technique for generating variable low-noise microwaves with a single optical microresonator.

The approach injects a microresonator frequency comb into a compact laser whose intensity is modulated by an off-the-shelf microwave oscillator. By forcing the modulation frequency to tightly follow a subharmonic frequency of the microwave produced by the microresonator frequency comb, the team successfully generated new microwaves whose frequencies can be varied significantly.

In addition, the newly generated microwaves show much lower phase-noise levels than those of a microresonator frequency comb oscillator and off-the-shelf microwave oscillators. This mechanism, called frequency division, is used to transfer the frequency purity of an optical signal into the microwave domain.

The developed technique enables the spectral purity transfer between different microwave signals. “Traditionally, executing perfect microwave frequency division in a variable fashion has not been easy,” explains Dr Wenle Weng, who led the study. “Thanks to the fast-modulated semiconductor laser developed by our colleagues at TCD and DCU, now we can achieve this using a low-cost photodetector and a moderate control system.” The semiconductor laser also generates a secondary frequency comb with more densified spectral emissions that can be useful in many spectroscopic applications.

The key components in the setup of the proof-of-concept experiment, including the microresonator and the semiconductor laser, are discrete and connected with lengthy fibers. The team is now working on integrating and advanced-packing the device. With the ability to be miniaturized and mass-produced, a variable microwave oscillator and frequency comb generator like that can revolutionize the current surging market for portable low-noise microwave and frequency comb sources.

Professor Tobias Kippernberg’s lab is part of EPFL’s Institute of Physics (IPHYS), situated in the School ofBasicsSciencesand the School of Engineering.

Swiss National Science Foundation

Defense Advanced Research Projects Agency, Defense Sciences Office (US)

Science Foundation Ireland (SFI)

SFI/European Regional Development Fund

Wenle Weng, Aleksandra Kaszubowska-Anandarajah, Junqiu Liu, Prince M. Anandarajah, Tobias J. Kippenberg, Frequency division using a soliton-injected semiconductor gain-switched frequency comb. Science Advances 25 September 2020: Vol. 6, no. 39, eaba2807. DOI: 10.1126/sciadv.aba2807