Medical X-ray imaging made affordable

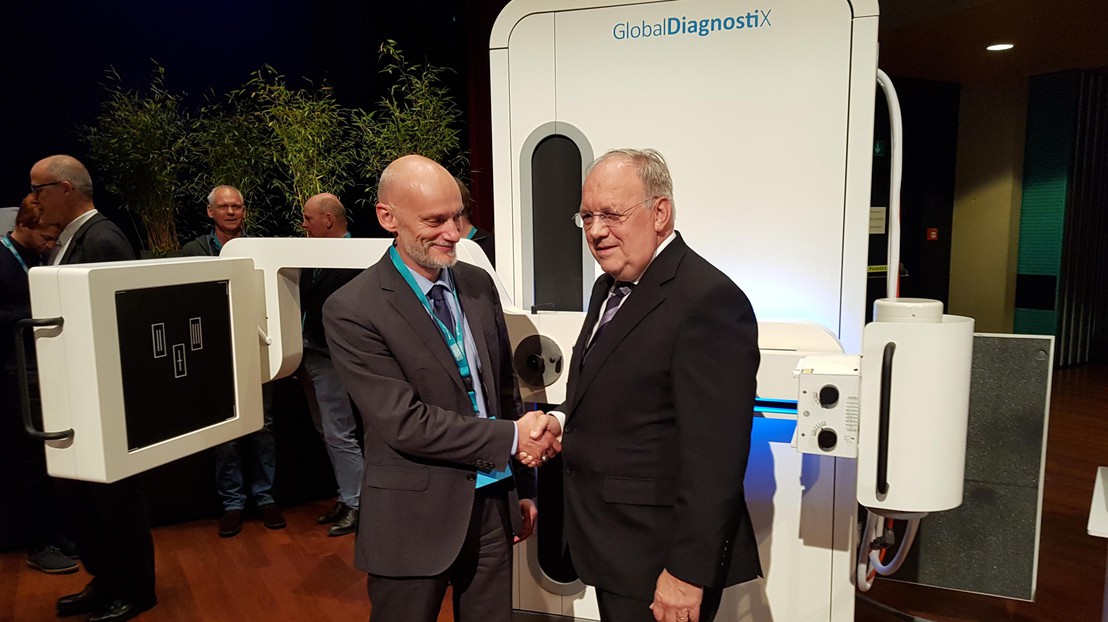

Klaus Schöneneberger, EssentialTech director, and Johann Schneider-Amman, Federal Councillor, with the prototype. © EPFL / E. Barraud

The GlobalDiagnostiX X-ray system is about to go into production. This robust machine – initially designed for the challenging conditions of countries in the Global South – has also turned out to be an attractive solution for industrialized nations owing to its low cost. The GlobalDiagnostiX consortium unveiled its second prototype on 29 October at an event that included Federal Councillor Johann N. Schneider-Ammann.

More than 120 years after X-ray technology was invented by Wilhelm Röntgen, medical radiography remains beyond the reach of two-thirds of the world's population. Yet it is an essential tool for diagnosing such things as car-accident injuries and infectious diseases like tuberculosis and pneumonia – the latter of which accounts for 20% of infant mortality. Developing countries in particular are unable to afford the high purchase and maintenance costs of X-ray equipment. What’s more, this equipment is ill-suited for operating environments marked by high temperatures and humidity levels and frequent power outages.

GlobalDiagnostiX aims to overcome these obstacles. The project was launched in 2012 as part of the EssentialTech program at the Ecole Polytechnique Fédérale de Lausanne (EPFL) in Switzerland, and brings together a large number of European and African universities and university hospitals. The result of their joint effort was unveiled on Monday in Yverdon-les-Bains, in Vaud Canton, before a small group of guests that included Federal Councillor Johann N. Schneider-Ammann, who heads Switzerland’s Federal Department of Economic Affairs, Education and Research.

A whole set of tailor-made solutions

The GlobalDiagnostiX X-ray system boasts an impressive array of innovations that were developed at EPFL in conjunction with the Universities of Applied Sciences and Arts of Western Switzerland (HES-SO). It was designed to stand up to demanding climate conditions without compromising on the quality of the X-ray images, and it offers a simple and intuitive interface.

The project engineers were guided by two principles – simplicity and robustness – to ensure the system could be maintained by relatively unskilled workers. The team also aimed at keeping the manufacturing and operating costs very low. “Even small hospitals – including in industrialized countries – will be able to afford this sophisticated X-ray equipment,” says Klaus Schönenberger, who runs the EssentialTech program. "Several teams of engineers, designers and medical radiology technicians of the HES-SO University of Applied Sciences and Arts collaborated to realize this high-tech prototype" says Olivier Naef, Head of the HES-SO Faculty of Engineering and Architecture .

First sales in 2020

With the research and development phase now complete, local startup Pristem SA will be in charge of manufacturing and marketing the machine. In August, this EPFL spin-off announced that it had raised 14 million francs in funding from a group of Swiss and African investors. “We’re now prepared to tackle the challenges of this global, highly diversified market by combining Switzerland’s time-tested manufacturing expertise with cutting-edge digital technology,” says Bertrand Klaiber, Pristem’s CEO, who expects to deliver the first machines already in late 2020.

In his remarks, Schneider-Ammann underscored the “excellent synergies between EPFL and the other specialized universities. Thanks to their agile teamwork, they were able to overcome significant hurdles and come up with a solution that will meet the needs of billions of people around the world.”