Loudspeakers in Jet Engines

© 2014 Alain Herzog

Unless one is attending an aeronautics convention or going on a trip, noise associated with aircraft engines is rarely tolerable. Different means of significantly reducing that noise are being tested by EPFL’s Electromagnetics and Acoustics Laboratory.

In Payerne this weekend, fighter planes once again will present their aerial prowess to the public. Long before their arrival at the site, the engines of certain aircraft will be audible as a deafening blare. At the entrance of the event, thousands of earplugs will be widely distributed to compensate for the noise that can reach 100 to 120 decibels at takeoff. This approaches the pain threshold for the human ear. European researchers are working on solutions to reduce noise at the source, in particular to reduce the irritation associated with flights. What’s more, a large increase in civil air traffic is expected in the coming years. This year the number of commercial flights is estimated at 30 million, and no fewer than 200 million are expected for 2020.

Different sounds emanate from an aircraft: jet noise, aerodynamic noise resulting from the turmoil around the landing gear and from the passage of air over the wing components, etc. But the most annoying to people on the ground is the “fan noise” related to the rotation of the engine blades during takeoff and landing. How might aircraft noise be reduced without changing the engine’s performance? One proposed solution is to integrate loudspeakers into the jet engine. The goal is to reduce noise by generating corresponding noise cancellation.

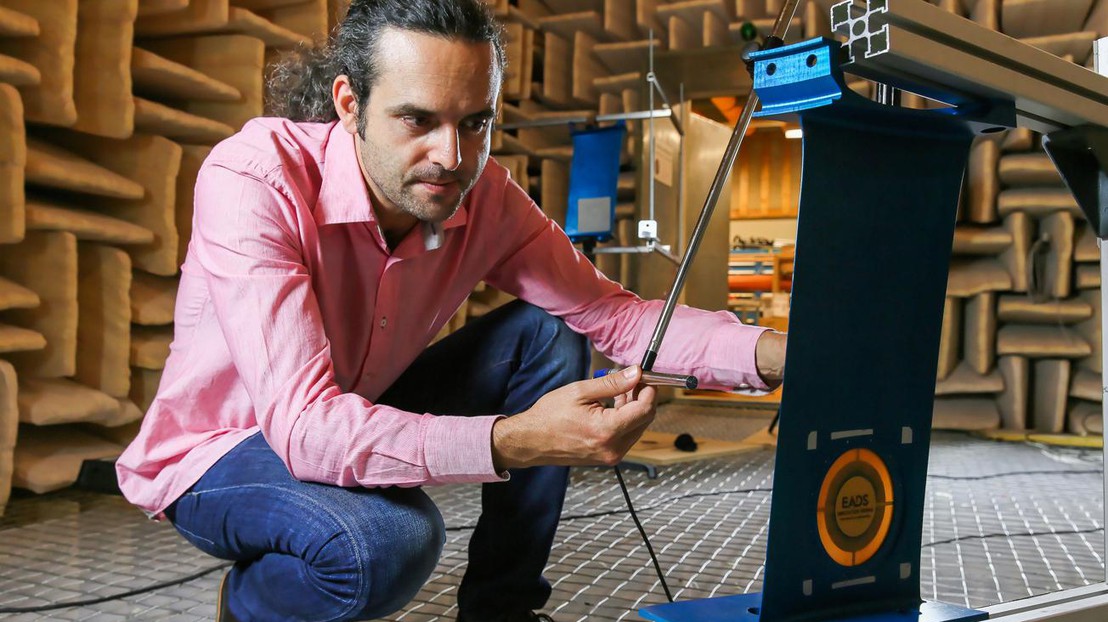

One of the main engine noises comes from the compression of air between the rotors, mobile parts of the motor and stators, consisting of static blades. One of the technologies developed in the framework of a European project, and currently being tested in the Electromagnetics and Acoustics Laboratory (LEMA), aims to integrate piezoelectric speakers into the blades of the stator. They function due to the property of certain materials to deform when an electric voltage is applied. A set of small microphones also placed in the engine captures the incident acoustic wave. They send the information to an electronic controller that calculates the signal to send to each of the loudspeakers integrated into the thirty blades to counter the wave coming from the reactor. “When they work together, the noise percived by the human ear can be reduced by 1.5 to 2 decibels” notes Hervé Lissek, head of the acoustic group of LEMA. This would be a true victory for our ears that could already be tested on aircraft within the next five years.

Given that the noise generated by an airplane comes from multiple physical sources that are characterized by different frequency ranges, further innovation is required in order to gain the six decibels specified by European research projects in this field. Other active speaker technologies developed by Hervé Lissek and his team focus on replacing the honeycomb-shaped layer of absorbent material around the jet engines. The method seeks to use the membrane of speakers as acoustic resonators with properties (such as resonant frequency and the damping factor) that can be adjusted by electrical means. The acoustic energy from the reactor can thereby be absorbed over a variable range of frequency.

Other techniques for active noise reduction are being developed by project partners. For example, a device based on micro-jets of air and placed around the nozzle of the engine could reduce the noise that results from turbulence in its output, which is dominant when the aircraft reaches cruising speed.