How can we use steel efficiently for sustainable design?

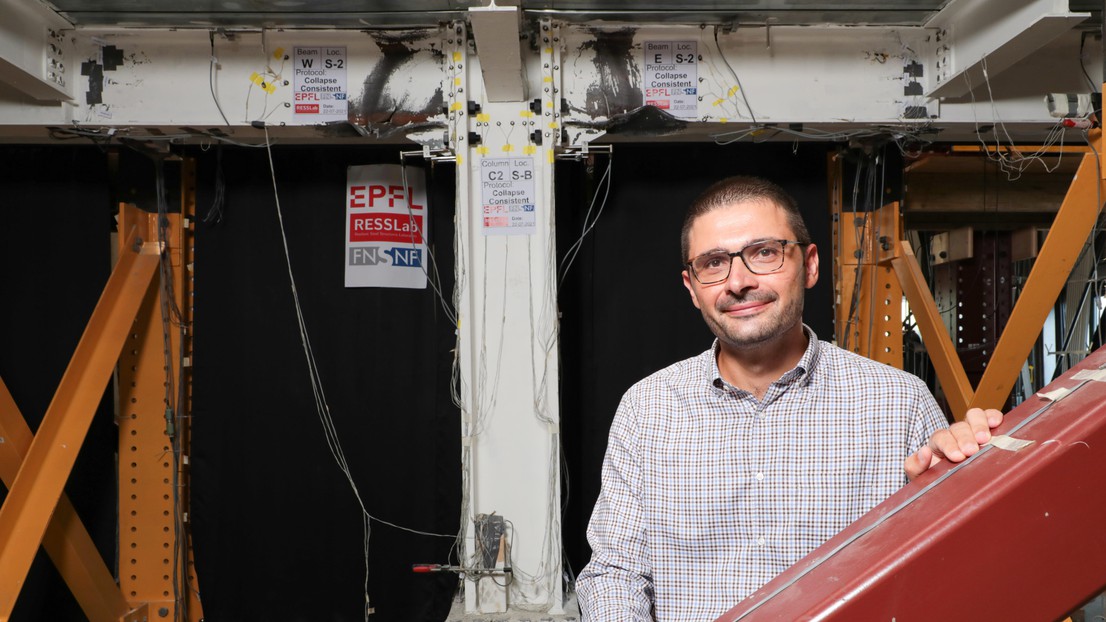

Dimitrios Lignos is the Director of the Civil Engineering Institute at EPFL. © EPFL/Alain Herzog

In this column, published in three regional dailies, Dimitrios Lignos, who heads EPFL’s Resilient Steel Structures Laboratory (RESSLab), explains how his laboratory's research is contributing to a more thoughtful use of steel in construction.

Embodied carbon in newly constructed buildings accounts for about 40% of greenhouse gas emissions worldwide. In addition, buildings experience considerable damage as a result of natural disasters, leading to staggering repair costs, downtime and displaced people, as we’ve seen several times in the past. Such damage is likely to occur more frequently due to climate change, since conventional construction materials are sensitive to extreme weather events over the long term. The effective use of structural steel could provide an interesting alternative for sustainable design, provided that engineers tackle a number of challenges.

Arguably, structural steel is better-suited for reuse than other construction materials are owing to its robust material properties and the minimal amount of reprocessing that’s required

Reusing structural steel

To be able to reuse steel members from end-of-life buildings, engineers need to explicitly consider potential geometric imperfections along with the actual mechanical properties of the members after they’ve been used. Here, the challenge stems from the complex phenomena associated with aging and the inelastic deformations caused by long-term effects coupled with mechanical loading. Arguably, structural steel is better-suited for reuse than other construction materials are owing to its robust material properties and the minimal amount of reprocessing that’s required. As our recent interdisciplinary research suggests, combining novel data-driven techniques with state-of-the-art simulation capabilities could make it easier for engineers to reliably predict the load-bearing capacity of steel members over their service life. In the end, engineers will need to incorporate limit state designs of recovered steel members that both meet the performance criteria of prospective building designs and allow for a more considered use of construction materials and resources.

Designing for deconstruction

One challenge in performance-based engineering for reuse is developing structural schemes that allow for deconstruction with minimal operating energy and effort. Similar concepts could also be applied to the development of easy-to-replace “sacrificial” fuses in structures. These fuses would contain any inelastic deformations occurring as a result of a natural disaster. This could bring several benefits. First, it would establish a simple way of separating construction materials without requiring energy-intensive operations. Second, it would speed the construction/deconstruction cycle. And third, it would enable a swift recovery of building functionality after a natural disaster, thereby reducing the losses from downtime and displaced people. At our EPFL lab, we’ve been developing and testing new structural steel schemes that deliver enhanced performance while retaining design simplicity.

Dimitrios Lignos, Full Professor of Civil Engineering, Director of the Civil Engineering Institute, and head of EPFL’s Resilient Steel Structures Laboratory (RESSLab)

- This article was published in October 2023 in three local dailies – La Côte (Vaud Canton), Le Nouvelliste (Valais Canton) and Arcinfo (Neuchâtel Canton) – under a joint initiative between EPFL and ESH Médias to showcase the R&D being carried out at EPFL on advanced construction techniques.