Grätzel solar cells get a boost

Grätzel cells now incorporate a new electrode made from titanium oxide nano-wires – three times more efficient.

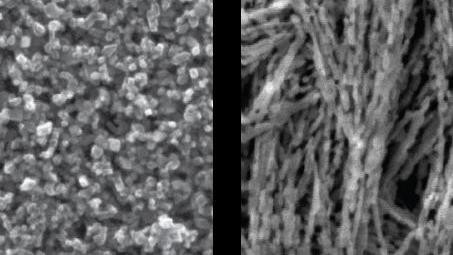

Solar cells using colorant, invented by Professor Michael Grätzel, represent one of the most promising solutions for the production of renewable, clean and inexpensive solar-cell energy. However, the most efficient Grätzel cells (yielding more than 11%) require the use of a liquid electrolyte, and may be subject to toxic leaks and corrosion. It has been proved that the use of solid organic materials can attenuate this problem, but the energy yield drops significantly. In an article recently published in ACS Nano, Dr. Nicolas Tétreault and his colleagues at EPFL’s Laboratory of Photonics and Interfaces, in cooperation with Dr. Endre Horváth and Dr. Arnaud Magrez and the scientists from the Laboratory of Physics of Complex Matter, propose a new solution – an electrode created by the auto-assembly of titanium oxide nano-fibers. The scientists have demonstrated a level of efficiency three times greater than comparable electrodes so far developed. The result is a robust Grätzel cell that is capable of converting 5% of solar energy.

“We were able to reach an almost-record level of efficiency using a new material that facilitates a faster and simplified synthesis. The objective has been attained by enabling efficient energy transfer, and an improved management of the light”, explains Dr. Tétreault.

This new electrode in titanium oxide nano-wire allows us to slightly increase the current in the cell. It provides a better conductivity and a much lower resistance. What’s more, we were able to increase the surface roughness of the electrode by nearly 60%. This roughness in turn enables a larger surface in contact with the colorant, and therefore an increased production of current. Lastly, this fiber network contains large pores, which allow an efficient diffusion of the light, while enabling better interaction with the colorant.

“The electrode is completely auto-assembled from a pure and inexpensive solvent solution, such as isopropanol. In the case of this new three-dimensional fiber network, the titanium oxide nano-wires auto-assemble in an almost perfect interconnected crystalline network. The procedure takes about 15 seconds, which represents a simplification that can yield a significant reduction in production costs”, concludes Dr Horváth who developed the synthesis of the nano-wires by hydrothermal treatment.

The editors of ACS Nano confirm that this fiber network presents new opportunities. Thanks to the ongoing collaboration between the group of Pr Grätzel and the group of Pr Forró, it is likely that this new electrode will enable flexible solar cells to reach new levels of efficiency very soon.