Experimental realization of a novel SOFC system

© 2019 EPFL

Experimental realization of a novel SOFC system with anode off-gas recirculation

Within the five-year RECOGEN project, the Group of Energy Materials (GEM) in partnership with the Laboratory for Applied Mechanical Design (LAMD) from EPFL and the industrial partner SOLIDpower designed, optimized, and experimentally realized a patented intermediated-temperature solid oxide fuel cell (SOFC) system with steam reforming (i.e., natural gas to hydrogen). The novelty of this system is a thermally-driven anode off-gas recirculation (AOR) fan, the so-called fan-turbine unit (FTU). The AOR has the advantage of higher global fuel utilization, and thus higher efficiencies and/or lower local fuel utilization, increasing the fuel cell stack lifetime. Additionally, the waste heat of the SOFC stack can be used for local cogeneration in heating or cooling applications. The absences of a water supply is another advantage in comparison to the state-of-the-art direct-steam supply SOFC system.

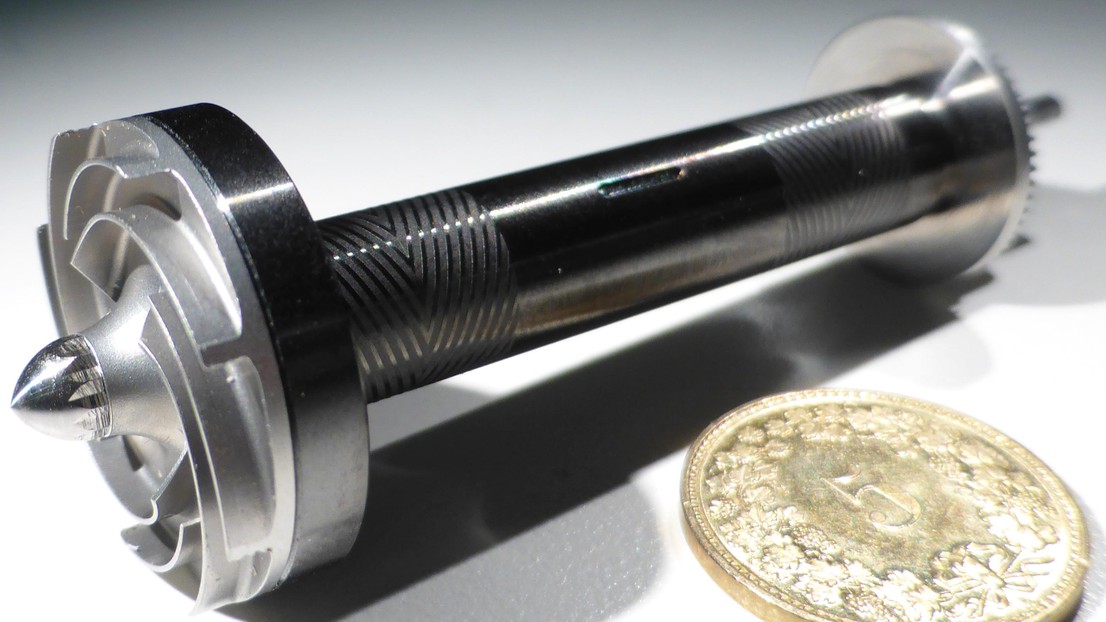

The FTU consists of a small-scale AOR fan, a steam turbine, and a shaft with gas film bearings. The radial inducer-less fan with a tip diameter of 19.2 mm features backward-curved prismatic blades. The radial-inflow, partial-admission (21 %), and low-reaction (15 %) steam turbine has a diameter of 15 mm. It consists of 59 prismatic rotor blades with a radial chord of 1 mm and a blade height of 0.6 mm. The shaft features one single-sided spiral-grooved thrust and two herringbone-grooved journal gas film bearings. Nominally, these bearings operate with water vapor at a temperatures of 220 °C and a rotational speed of 175 krpm. The entire unit is manufactured by milling, turning, and surface finishing operations (i.e., grinding and honing) exclusively. The unit design is focused on low manufacturing cost, high lifetime, as well as oil-free and explosion-proof operation.

A first proof-of-concept of this novel SOFC system was experimentally realized in the facilities of SOLIDpower in Yverdons-les-Bains, Switzerland, from December 13 to 14, 2018. The FTU was coupled in-situ to a 6 kWel SOFC system, reaching electrical gross DC efficiencies, based on the lower heating value (LHV), of 66 % in part load (4.5 kWel) and 62 % in full load (6.4 kWel) for a global fuel utilization of 85 %. At constant fuel mass flow rate and a constant global fuel utilization of 75 %, the AOR improved the electrical gross DC efficiency by 5 percentage points (from 52 % to 57 %), compared to a direct-steam supply SOFC system. The stack local fuel utilization dropped from 75 % to 61 %, suggesting an increase of the stack lifetime while improving its efficiency.

To the best of author’s knowledge, this is the first time that such an SOFC system was demonstrated. It can contribute to make the SOFC technology more efficient, more reliable, more cost-effective, and thus more competitive. This research will be continued within the EU-funded project “Blaze”.

Canton de Vaud, program “100 millions for renewable energy and energy efficiency”