Eco-mouse wins student prize of innovation and entrepreneurship

© 2024 EPFL

In the fifth anniversary edition of the graduate course “Innovation and Entrepreneurship in Engineering,” students across many disciplines at EPFL tackled prototyping challenges related to the development of energy-efficient devices. Led by Prof. Véronique Michaud and Prof. Thomas Weber, and supported by a diverse group of additional faculty, nine student teams engaged in various industrial challenges, in collaboration with this year’s industry sponsors Boschung Mecatronic, Datwyler, Logitech, Schindler, and ZF Group. In addition to finding an innovative technological solution with a viable business model, the challenge included a quest for energy efficiency. This year’s winning team provided a bio-based alternative to conventional plastic used in the manufacturing of Logitech computer mice.

What does a snow plough and the latest version of a gaming mouse have in common? Whether you are an engineer designing a smart network of sensors to assess the conditions of the asphalt on Swiss highways, or a keen gamer getting ready for your best performance during your gaming night, you could probably find yourself asking some of the following questions: How long will the battery of my device last? Will I need to replace it often? Could there be a way for the device to generate the energy it needs to function?

Energy efficiency has become a key topic in our era dominated by the climate crisis, and many industries are willing to take action to decrease the environmental impact of their technologies. One possible approach is to rethink the way our devices generate, store, or consume power to perform their functions. However, companies often struggle to implement novel solutions for energy generation and storage within existing products—due to operational constraints, the associated significant investments, or the uncertainty about market acceptance. Therefore, multiple sponsors proposed project ideas for students of the EPFL graduate course on Innovation and Entrepreneurship in Engineering (IEE), addressing the following challenge: How can we design an energy efficient device, capable of producing and storing the energy it needs?

During the IEE 2024 course, offered jointly by the College of Management of Technology (CDM) and the School of Engineering (STI) since 2019, nine teams prototyped proof-of-concept solutions addressing technical characteristics and developed economically and ecologically viable business plans.

Team 1: FAST IOT

Students: Ismael Tobias Frei (EL), Aurélien Pierre Joseph Laissy (GM), Matteo Peduto (GM), Jan Peter Reinhard Clevorn (EL), Hugo Bernard Adrien Penichou (GM).

Industry partner: Daniel Esteves (Boschung Mecatronic AG)

Switzerland is very well known for its glaciers, yet ice formation on roads and ramps are far from being a desirable substitute for the formerly perennial snow fields. Boschung Mechatronic has been a key player in Switzerland fostering the development of antifreezing and deicing solutions for airports, highways, and citites. Their challenge for the students was to develop an anti-freeze system for private users who wish to have a low-cost and easy-to-install solution on their proprietary roads and ramps. The team proposed “ThawPal,” a system composed of an antifreeze-liquid generator and a smart spraying system that can be controlled through a dedicated smart app, allowing for real-time process monitoring and control, as well as integration with weather data. The team also brought the prototype to the field, testing it on the ramps of Martigny Hospital, showcasing the easy installation and control of the components.

Team 2: Pavement Sensor loT

Students: Dorian Jean Agrati (GM), Vincent Jonathan Thomas Zanada (MX), Benjamin Michael Colety (GM), Talha Balin (MTEE), Samuel Darmon (SIE).

Industry partner: Daniel Esteves (Boschung Mecatronic)

Monitoring road conditions, such as the amount of water on the asphalt or its temperature, is crucial to ensure that the infrastructure is in good condition and properly maintained. The team behind PAVE IoT worked together with Boschung to develop a device able to monitor road conditions, communicate wirelessly with a computer, and produce the energy needed for its operation. The team designed a network of devices to be installed on bike lanes and roads that can also be used by municipalities to map road conditions, supporting their decision on whether to deploy deicing equipment on any given day. Some further development is needed to ensure that these devices can operate autonomously for a long time, highlighting a challenging technical question: How can energy be harvested from roads?

Team 3: Electrically Conductive Rubber To Be Used as Strain Sensor

Students: Raphaelle Allison Paracuellos (GM), Olivier De Campos-Delmée (GM), Aliana Matea Desmeules (MX), Pia Elisa Friederike Rosenkranz (MX), Noah Grosjacques (MX).

Industry partner: Sven Gisler (Datwyler), Camille Gilbert (Datwyler)

Virtual reality (VR) is a key topic that has started to become part of our daily lives, from the way we interact on social media, to the means by which we can experience an art exhibition. The development of hardware to support VR relies on the precise movement capture of various body parts, for example a user’s hands. In collaboration with Datwyler, a Swiss manufacturer of advanced elastomers, the students explored the field of VR hardware. By leveraging the industry partner’s conductive rubber, the team prototyped “TechTouch,” a glove that tracks finger movements and is designed to be a low-cost alternative to mainstream VR gloves. Relying on flexible parts and low-power electronics, TechTouch demonstrates an interesting approach to open up Datwyler to hitherto-unanticipated applications, aiming also for a democratization of this advanced technology through a comparatively low-cost approach.

Team 4: Energy Harvesting Using Nanogenerator-Elastomers

Students: Martino Allegri (GM), Aurora Ruggeri (GM), Victoria Jeanne Marie Chalain (MT), Thomas Carlos Rudi Cañellas Rey De Vinas (SV), Allegra Magnetti (MX).

Industry partner: Sven Gisler (Datwyler)

According to the European Agency for Safety and Health at Work (EU-OSHA), almost 49 million workers are regularly exposed to vibrations, potentially leading to the development of Hand-Arm Vibration Syndrome (HAVS). HAVS is a severe health risk, with irreversible damages to joints, blood vessels, and nerves, thus requiring workers to undergo periodic preventative check-ups. Team 4, with its “TENGlove,” decided to exploit Datwyler’s triboelectric rubber, a material that can transform the mechanical energy of vibrations into electrical energy, to develop a smart glove that senses the amount of vibration, and communicate to the user when a significant safety threshold has been exceeded. As a future outlook, TENGlove aims at advancing the glove one step further, by using the triboelectric rubber to generate the energy needed for the glove to function, thus avoiding the need for battery power.

Team 5: Autonomous Mouse

Students: Zoubida Squalli Houssaini (GM), Viviane Marie Odile Blanc (GM), Feraol Ibrahim (MT), Roan Joseph André Nones (GM), Mohamed Shahine Alhilali (GM).

Industry partner: Stéphane Rochat (Logitech)

The "Autonomous Mouse" project details the development of a groundbreaking wireless mouse that operates independently without the need for traditional power sources such as batteries or electric outlets. By collaborating with Logitech and integrating innovative microgenerator technology from Kinetron, the team successfully demonstrated the feasibility of an energy-efficient mouse concept. Despite initial concerns about reliance on external suppliers, the project's simulations and optimizations confirmed the effectiveness of the autonomous-energy solution. While facing challenges such as incomplete data for a comprehensive life-cycle analysis, the team's long-term strategy focused on creating a self-sustaining gaming mouse to address environmental issues associated with disposable batteries, marking a significant advancement in computer-accessory technology.

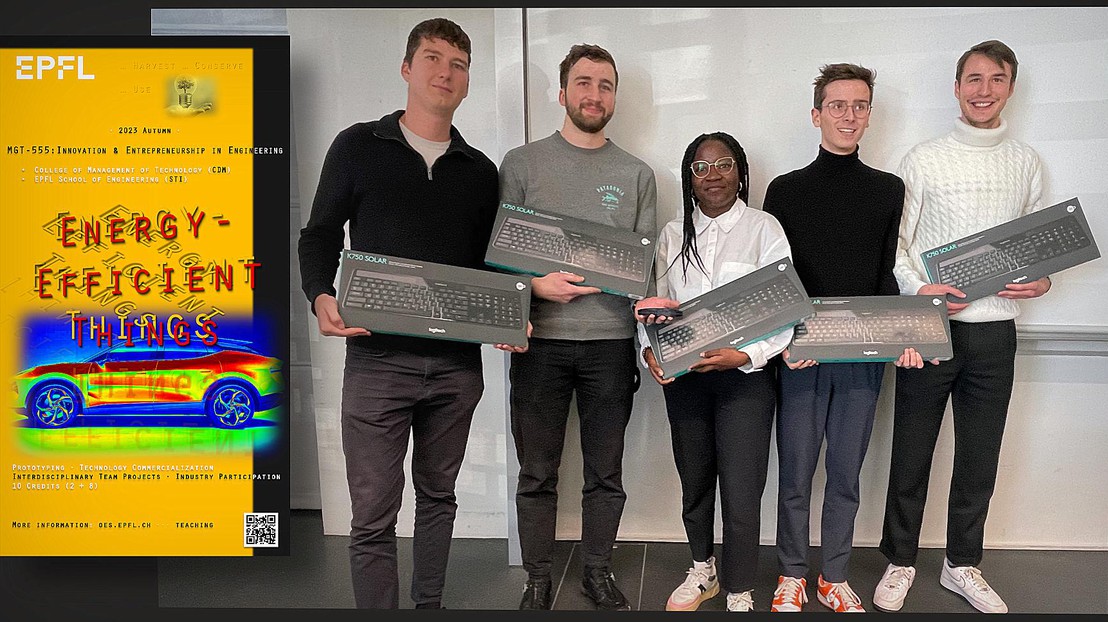

Team 6: Eco-Design Plastic

Students: Victoire Sephora Tchatat Njieyep (GM), Emilien François Ancey (MX), Paul Louison Nathan Hardivillé (MX), Jules Édouard Dominique Thierry Sachot-Durette (GM), Niels Uythoven (MX).

Industry partner: Stéphane Rochat (Logitech), Kathy Liu (Logitech), Kevin McDonnell (Logitech), Dr. Philip Scholten (Bloom Biorenewables SA)

Team 6 focused on developing an eco-plastic computer mouse, exploring sustainable material alternatives to traditional plastics in tech accessories. The emphasis was on designing a recyclable plastic shell and investigating materials such as recycled PET, ABS, and bio-based plastics. The team proposed a short-term solution with a new design for easier recycling, as well as a long-term solution using a biopolymer derived from waste from wood production in Logitech products. Market analysis, customer segmentation, a business model, and sustainability evaluation were also included, aiming to balance ecological responsibility with economic viability. The judges were impressed overall by the elegance of the mouse assembly and disassembly, as well as the substantial positive environmental impact that could be realized.

Team 7: Living Reusing Heat for Greenhouse and Building Heating

Students: Mohammad Harar Safazada (GM), Marco Karam (GM), Oulaya Darbi (EL), Antoine Nicolas Morel (GM), Mehdi Hussaïn Kanani (NX).

Industry partner: Dr. Malcolm Mielle (Head of Schindler Lab EPFL)

Team 7 introduced an innovative solution for urban greenhouses, utilizing waste heat from elevator motors to enhance buildings’ energy efficiency and reduce their carbon footprint. This approach may be incorporated into local food production, urban cooling, and can offer economic benefits by lowering heating costs. The project leveraged unused rooftops for sustainable agriculture, targeting the Parisian market initially. The group included a detailed business model with revenue from sales, subscriptions, and maintenance services, aiming for significant growth by 2030. Their solution was designed to address urban challenges, including sustainability goals and the enhancement of livability within cities.

Team 8: Sustainable Grid Management Infrastructure Solutions for eTrucks eBuses and eTrailers

Students: Jean-Baptiste Marie Alexandre Poussin (GM), Gabriel André Veigas Marques (MT), Valentine Hélène Laurence Houlier (GM), Antoine Louis Avellaneda (GM), Lina Bousbina (SC), Sébastien Bruno Jérome Roux (GM).

Industry partner: Marco Eid (ZF Group), Prof.André Hodder (STI, EPFL)

Team 8 presented an innovative energy-optimization solution for commercial-vehicle battery-swapping stations. The project introduced a smart algorithm integrated with an energy-buffer system, utilizing repurposed EV batteries to enhance efficiency, reduce costs, and support sustainability in commercial transportation. The solution aims to streamline energy management and charging processes, offering significant operational improvements and environmental benefits. The group outlined a comprehensive business model, including market analysis and sustainability evaluation, highlighting the project's potential to address the challenges in the transition to electric vehicles, thus contributing to a more sustainable future in transportation.

Team 9: Next-Generation Battery Electric Fuel Cell Commercial Vehicle

Students: Ennio Zemolin (GM), Marco De Pascalis (GM), Emeric Martin (GM), Xavier Thomas Barthez (GM), Jadd-Ilyes Djilali Ali Larbi (GM), Alexis Nathan Pierre Firome (SC)

Industry partner: Marco Eid (ZF Group)

Team 9 blueprinted an innovative solution for the next generation of battery-electric/fuel-cell commercial vehicles, focusing on modular cabins for autonomous trucks. It covers comprehensive analyses including computational fluid dynamics for drag reduction, electric system development and fast charging infrastructure, alongside a detailed market analysis, business model and sustainability evaluation. The team emphasized technological advancements, such as swappable batteries and renewable energy integration, to enhance efficiency and sustainability in the trucking industry. The project aimed to significantly reduce CO2 emissions and operational costs, positioning it as a key advance in the domain of sustainable transportation.

2024 IEE Prize – Results

Energy efficiency is a key aspect to developing future sustainable technologies. From the manufacturing of innovative materials to optimized transport and logistics, energy plays a crucial role in every step of the value chain. However, the quest for energy efficiency can be tackled in multiple ways: Can a device reduce the amount of energy needed for it to function? Can energy be stored in a more efficient way? Is it possible to harvest energy from the sourrounding environment, making a product more energy autonomous? These were some of the challenges that drove the teams of the 2024 IEE course. The jury was impressed by the creative ways that the different industry problems were tackled and how the students combined technical solutions and business model innovation. All presentations were rated by the quality of the business case, functionality of the prototype, and overall professionalism.

The first prize was awarded to Team 6, working in collaboration with Logitech to develop a more sustainable type of plastic to be used for computer mice. The team reached out to EPFL’s startup Bloom Biorenewables, to understand how to use their bioplastic derived from the waste of wood production. The team showcased the feasibility of integrating the bioplastic into conventional manufacturing processes that could be used by Logitech to produce a case for their mice. Furthermore, the team proposed a design-for-recycling approach, proposing a new mouse deisgn that is easier to dismantle at its end-of-life. After careful deliberation by the jury, the 2024 IEE Prize for the best project in this academic year’s course “MGT 555: Innovation and Entrepreneurship in Engineering” was awarded to the Eco-Design Plastic project.

This year’s runner-up was Team 4 with their smart work glove for the detection of vibrations. The group impressed the jury by developing an innovative solution based on Datwyler’s synthetic rubber material, integrating a commercial work glove with sensing pads capable of measuring the amount of vibrations that a worker is exposed to, and to warn the user when the amount of vibration exceeds a prespecified safety level. Adopting such a glove in workplaces with vibration exposure, the team proposes a solution for the early prevention of diseases caused by the continuous exposure to vibrations.

***

The fifth anniversary edition of the course was supported by faculty and experts, at EPFL and beyond, contributing with their expertise in technology prototyping, economic evaluation, and sustainability assessment, including (in order of appearance) Prof. Christopher Tucci [Imperial College London]; Prof. Sophia Haussener [LRESE, EPFL]; Pascal Vuilliomenet [Engineer, ETS/HES EPFL]; Margaux Peltier [CEO & Co-founder, Enerdrape]; Dr. Martyn Wakeman [LPAC, EPFL]; Prof. Manuele Margni [HES-SO Valais]; Prof. Andreas Burg [TCL, EPFL]; and Dr. André Catana [STARTUP, EPFL]. The course was coordinated by the doctoral students Ru Zhang [OES, EPFL] and Lorenzo Lucherini [SMAL, EPFL]. Valuable administrative assistance was provided by Ilona Ball [OES, EPFL].

The instructors are indebted to the Vice-Presidency for Innovation, in particular Sébastien Genet [VPI, EPFL] for helping with industry relations, as well as Pascal Vuilliomenet [Discovery Learning Laboratories, EPFL], together with Julien Delisle [Coordinator, MAKE Initiative], for initiating the students to the hands-on prototyping facilities at EPFL. A very special thank you also goes to the two expert members of the jury, Dr. Marc Laperrouza [Scientist, CDH, EPFL] who has been on the prize jury since the beginning of the course in 2019, and Dr. Nicolas Cudré-Mauroux [CTO, SICPA] who contributed his broad expertise on materials and innovation. The instructors are also very grateful for the support of the companies and their very engaged managers who spent much time with the students: Daniel Esteves (Boschung Mecatronic), Sven Gisler (Datwyler), Stéphane Rochat (Logitech), Dr. Malcolm Mielle (Schindler), and Marco Eid (ZF Group). Finally, the course could not have been undertaken without the strong support of Prof. Ali Sayed [Dean, School of Engineering, EPFL] and Prof. Rüdiger Fahlenbrach [Dean, College of Management of Technology, EPFL] who shared the financial support for the student projects.

The next edition of the course MGT-555 Innovation and Entrepreneurship in Engineering, in the fall of 2024, will take place under the theme of “Devices for a Circular Economy,” organized again jointly by Prof. Thomas Weber and Prof. Véronique Michaud.