Desalinating water in a greener and more economical way

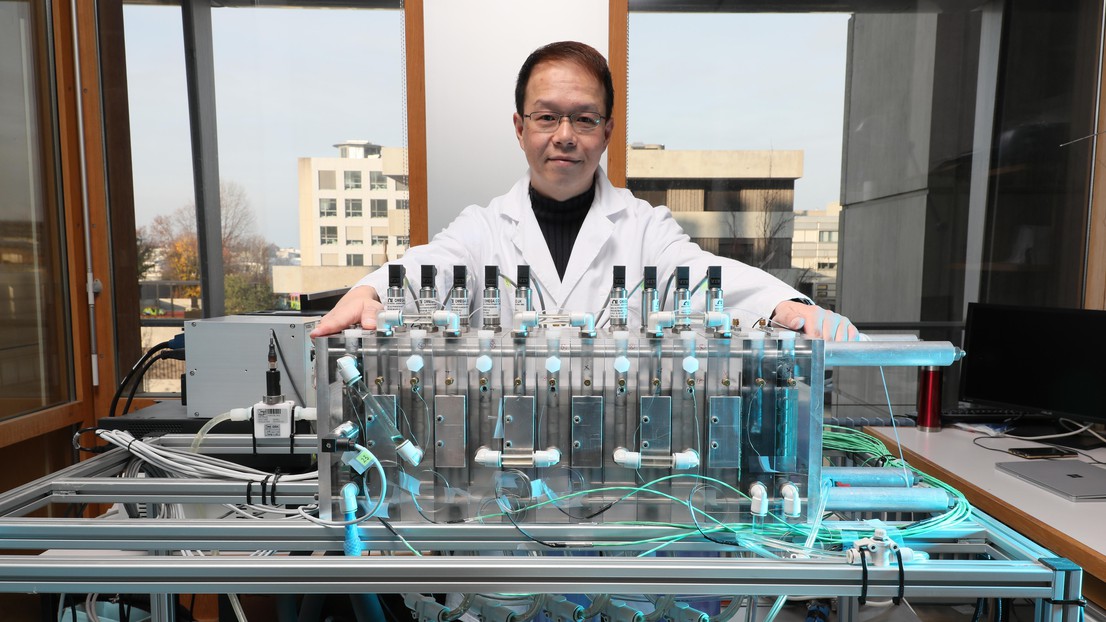

Jeff Ong, a mis au point un dispositif permettant de désaliniser l'eau de manière plus écologique © 2019 EPFL

Researchers at EPFL have developed a machine that turns seawater into drinking water in a more environmentally friendly and economical way than existing systems. A spin-off, Aqualife Global, has now been set up to develop and commercialize the technology.

We know that excessive consumption, industrial activity and growth in the global population are some of the factors threatening access to drinking water for an increasing proportion of people around the world. According to UNESCO figures from 2012, almost 700 million people suffer from limited access to water – and that number could rise to 1.8 billion by 2025. Desalination and the treatment of industrial wastewater can produce large amounts of drinking water, and these methods are already used in many countries and regions such as the United Arab Emirates, Saudi Arabia, China, Europe and the USA. However, existing systems are costly and use a lot of energy. Jeff Ong, from EPFL’s Laboratory of Inorganic Synthesis and Catalysis, has developed a water treatment machine that combines the benefits of all of the main technologies currently being used while offering improved performance. For example, the prototype removes more than 99.9% of the salt from seawater with the same throughput but using less energy. The system will be tested in real-world conditions this year.

Increasing throughput

The main large-scale desalination technology used today is reverse osmosis. When two identical liquids separated by a semi-permeable membrane have a different concentration of salt or other minerals, the one with the lower concentration passes through the membrane until each liquid has the same concentration. To reverse this natural process and therefore maximize the amount of fresh water, pressure is applied to the more concentrated liquid so that it flows through the filtration membrane towards the drinking water side. The technique uses a relatively large amount of electricity (around 4–5 kWh/m3) and the membranes deteriorate rapidly, as do other components, worn down by mineral particles. They need to be chemically cleaned several times per year and replaced very frequently. “That results in high maintenance costs for producers,” says Ong. However, the desalination concept used by the EPFL spin-off use membranes made of inert hydrophobic material, wear out less quickly and can be recycled cheaply.

Evaporating water using heat recovery elements

To maximize salt separation, which the EPFL prototype increases to more than 99.9%, Ong put together a series of evaporation-based desalination modules. To address the system’s main weakness – energy consumption – he made several improvements including internal heat recovery and more efficient heat transfer. By reducing the pressure, the water can be brought to a boil at a temperature of less than 80°C. The vapor produced is cooled and recovered as fresh water. The rest of the liquid, which contains the remaining salt, passes into another cell with even lower pressure, and so forth. Heat recovery elements are used to pre-heat and vaporize the remaining saltwater, without using any energy from outside the system. At each stage, the vapor produced is cooled and the resulting fresh water is recovered. The fresh water is removed using heat exchanger devices that are positioned so as to cool the system. By reusing heat that would otherwise be lost, E-METS has a much lower carbon footprint than a conventional thermal system. “These evaporation and cooling flow principles are commonly employed in the nuclear power industry”, explains Ong. “We are the first to apply the concept in the water separation field.”

Treating very salty water

Recent improvements in this hybrid prototype have also resulted in time savings, because throughput is now up to twice as high as that of reverse osmosis systems. In addition, the new system has the advantage of being able to handle very high salt concentrations – more than 200 g/l – which is twice as much as standard thermal separation technologies and more than four times as much as reverse osmosis. Such high salt concentrations can be found, for example, in the waste solutions produced by reverse-osmosis plants.

The desalination market is expected to be worth $27.4 billion in 2025, with the water and water treatment market overall worth $675 billion. The start-up, Aqualife Global, is currently in incorporated to commercialize the E-METS technology. The modular arrangement of the system means that it can be adapted to the amount of water to be treated. This year, the co-founders intend to develop a version that fits into a shipping container, making it easy to transport and allowing it to be set up where it is most needed. As well as being used to desalinate seawater, the system can be connected to reverse osmosis plants, helping them to produce higher volumes of desalinated drinking water. The co-founders also see many other potential applications, such as treating wastewater from the mining industry – and more specifically for lithium mining – and removing sulfur from wastewater produced by electricity generation companies. The system could also be used to treat wastewater produced by the agri-food and oil and gas industries.