Deployable electrodes for minimally invasive craniosurgery

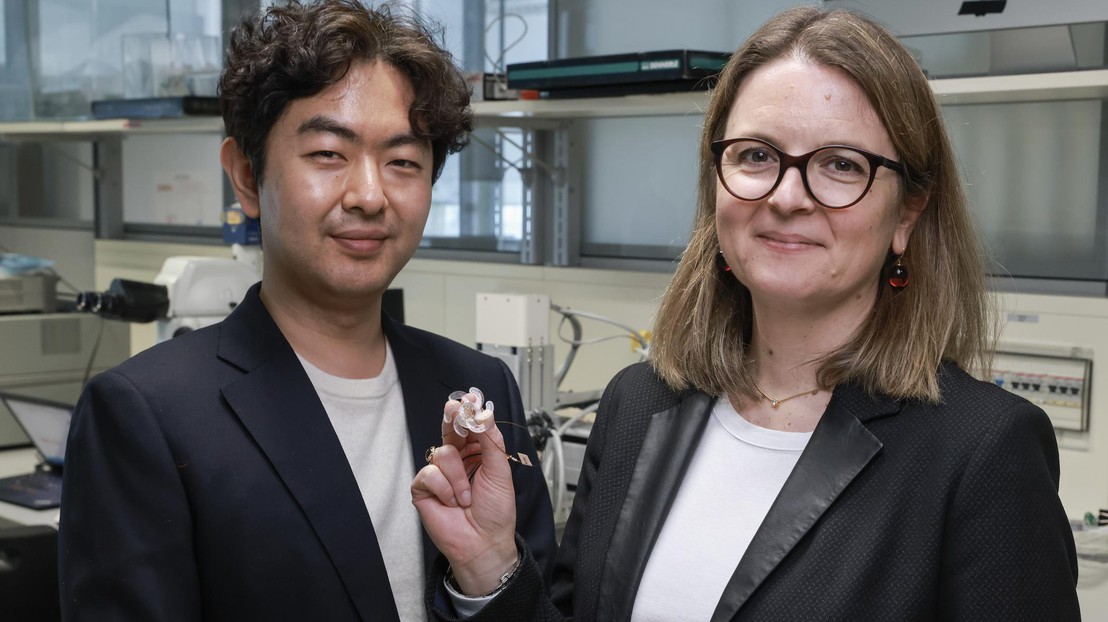

Sukho Song and Stéphanie Lacour with the deployable electrode. Credit: 2023 EPFL/ Alain Herzog.

EPFL scientists have developed electrode arrays that can be funneled through a small hole in the skull and deployed over a relatively large surface over the brain’s cortex. The technology may be particularly useful for providing minimally invasive solutions for epileptic patients.

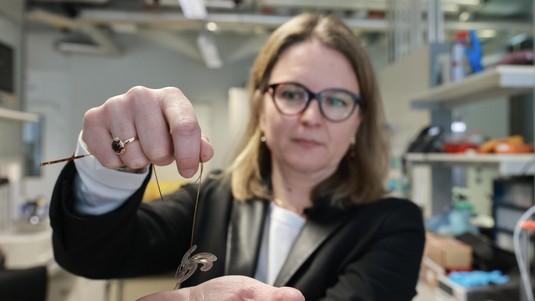

Stephanie Lacour, head of the Laboratory for Soft Bioelectronic Interfaces (LSBI) in the School of Engineering, specializes in the development of flexible electrodes that adapt to a moving body, providing more reliable connections with the nervous system. Her work is inherently interdisciplinary.

So when a neurosurgeon asked Lacour and her team to come up with minimally invasive electrodes for inserting through a human skull, they came up with an elegant solution that takes full advantage of their expertise in compliant electrodes, and inspired by soft robotics actuation. The results are published in Science Robotics.

The challenge? To insert a large cortical electrode array through a small hole in the skull, deploying the device in a space that measures about 1 mm between the skull and the surface of the brain – without damaging the brain.

“Minimally invasive neurotechnologies are essential approaches to offer efficient, patient-tailored therapies,” says Stéphanie Lacour, professor at EPFL Neuro X Institute. “We needed to design a miniaturized electrode array capable of folding, passing through a small hole in the skull and then deploying in a flat surface resting over the cortex. We then combined concepts from soft bioelectronics and soft robotics.”

From the shape of its spiraled arms, to the deployment of each arm on top of highly sensitive brain tissue, each aspect of this novel, deployable electrode is ingenious engineering.

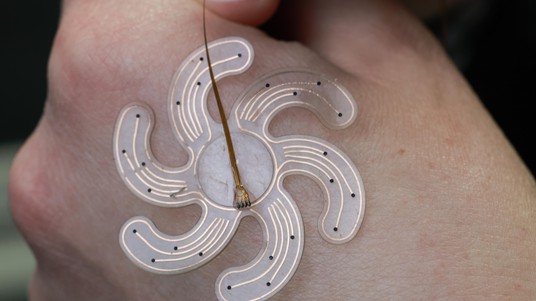

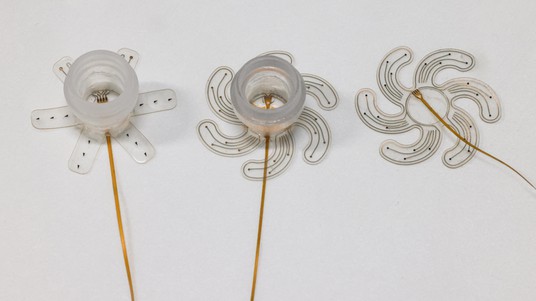

The first prototype consists of an electrode array that fits through a hole 2 cm in diameter, but when deployed, extends across a surface that’s 4 cm in diameter. It has 6 spiraled-shaped arms, to maximize the surface area of the electrode array, and thus the number of electrodes in contact with the cortex. Straight arms result in uneven electrode distribution and less surface area in contact with the brain.

Somewhat like a spiraled butterfly intricately squeezed inside its cocoon before metamorphosis, the electrode array, complete with its spiraled-arms, is neatly folded up inside a cylindrical tube, i.e. the loader, ready for deployment through the small hole in the skull.

Thanks to an everting actuation mechanism inspired from soft robotics, each spiraled arm is gently deployed one at a time over sensitive brain tissue. “The beauty of the eversion mechanism is that we can deploy an arbitrary size of electrode with a constant and minimal compression on the brain,” says Sukho Song, lead author of the study. “The soft robotics community has been very much interested in this eversion mechanism because it has been bio-inspired. This eversion mechanism can emulate the growth of tree roots, and there are no limitations in terms of how much tree roots can grow.”

The electrode array actually looks like a kind of rubber glove, with flexible electrodes patterned on one side of each spiral-shaped finger. The glove is inverted, or turned inside-out, and folded inside of the cylindrical loader. For deployment, liquid is inserted into each inverted finger, one at a time, turning the inverted finger right side out as it unfolds over the brain.

Song also explored the idea of rolling up the arm of the electrode as a strategy for deployment. But the longer the arm, the thicker it becomes when rolled up. If the rolled-up electrode becomes too thick, then it would inevitably take up too much room between the skull and the brain, placing dangerous amounts of pressure on the brain tissue.

The electrode pattern is produced by evaporation of flexible gold onto very compliant elastomer materials.

So far, the deployable electrode array has been successfully tested in a mini-pig. The soft neurotechnology will now be scaled by Neurosoft Bioelectronics, an EPFL spin-off from the Laboratory for Soft Bioelectronic Interfaces, that will lead its clinical translation. The spin-off was recently granted 2.5 million CHF Swiss Accelerator by Innosuisse.