Demonstrating geological CO2 storage on the EPFL campus

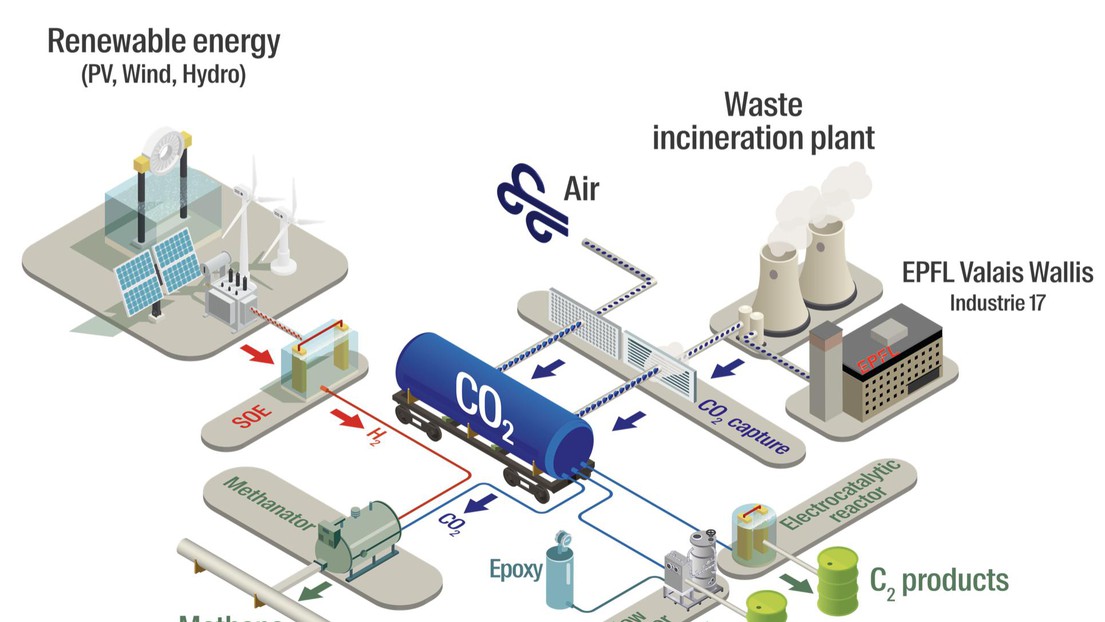

The proposed CCUS demonstrator near the EPFL Valais campus. © 2023 EPFL

The Laloui Group is developing a first-of-its-kind geological CO2 storage simulator to ensure safe and reliable carbon capture and storage.

The role that atmospheric carbon dioxide (CO2) plays in warming the climate is now well understood, and as the concentrations of anthropogenic CO2 continue to increase in the atmosphere, there is an urgent need to reduce them significantly. Recognizing this challenge and aligning with its 2030 Climate & Sustainability Strategy, EPFL launched the ‘Solutions4Sustainability’ initiative to fund an EPFL integrated research and innovation plan to reduce the School’s energy dependence and carbon footprint. A total of CHF 9 million has been granted to develop a closed Carbon Capture, Usage, and Storage (CCUS) loop on campus, including demonstrators and solutions ready for scale-up.

The project known as Energy-efficient CCUS for Sustainable and Circular Economy (SusEcoCCUS) is housed at EPFL Valais. It aims to reduce the CO2 footprint of the campus by capturing and processing one ton per day of point source and atmospheric CO2. From here, short and long-term CO2 storage technologies will be developed and enhanced, and technologies for converting the CO2 into energy carriers and value-added chemicals will also be deployed.

Under the direction of Dr. Eleni Stavropoulou, the Laloui Group is leading the CO2 storage activities of this ambitious project. In the field, CO2 is captured and injected in underground porous reservoirs at depths greater than 800 meters. An impermeable geological layer, the caprock, overlays the storage reservoir to prevent CO2 from escaping to the surface. Our team will develop a unique, meter-scale GCS experiment at EPFL’s Lausanne campus to inject and store CO2 captured from EPFL sources to enhance the safe implementation of large-scale GCS.

FIRST OF ITS KIND

The unique CO2 storage simulator will enable, for the first time, a tangible link between lab and field scales. In recent years, there has been important progress in understanding the multi-physical processes that take place between the different geomaterials (reservoir, cap rock) and the injected CO2 in the lab. However, implementing these findings (millimetric scale) to large-scale models (kilometric scale) to simulate real-field conditions is not straightforward, but then, neither is field monitoring. It is limited in resolution, expensive, and often unavailable to the wider scientific public. By introducing this novel intermediate scale of observation, it will be possible to develop a natural bridge between the two existing scales, enabling a better understanding of the geomechanical processes that occur in space and time.

Beyond the scale of the simulator, the storage experiment has several other firsts. Rather than pure lab-grade CO2, the simulator will use real EPFL-captured CO2 of 98% purity, allowing the impact of the CO2 consistency on the injection and storage performance to be additionally evaluated. The simulator will also explore different injection strategies and examine the risk of leakage under controlled conditions.

WORTH THE EFFORT

Despite the many firsts and challenges involved in conducting a simulated environment at this scale, Dr. Stavropoulou says the rewards will be well worth the effort. “To reproduce real-field conditions at this scale is a real challenge: at a depth of 1 km, pressures and stresses are very high. On the other hand, our experiment’s results will be ground-breaking, which is really motivating. We will employ cutting-edge, high-resolution 3D monitoring that is impossible in the field and join small-scale experiments with real-world conditions,” she explains. “The scale we introduce will provide unprecedented information and allow us to link small-scale findings to real-field observations such as CO2 distribution and caprock sealing capacity. Small-scale experiments are much easier to monitor and control, yet the realism of results at such a small scale is often questionable. In real-world field injection campaigns, we face the opposite problem as we have limited capacity to monitor the injection process, which is usually limited to the close proximity of the injection well.”

The ultimate goal of this simulator is to provide meaningful 3D data that will significantly strengthen the numerical models being developed, leading to the design of injection strategies that will ensure the safety of future GCS selection sites, including in Switzerland. Stavropoulou thinks the rewards will be worth the effort. “We have a real chance to significantly contribute to one of our greatest modern-day challenges, climate change. If we can help demonstrate a closed-loop carbon capture and storage solution, it can be scaled up and distributed worldwide, and that would be an amazing contribution.”

SusEcoCCUS started on the first of October, and early results are expected in mid-2024. Further details and updates can be found on the SusEcoCCUS website.

EPFL Solutions4Sustainability Fund