Clever device drastically reduces the vibration from rotating parts

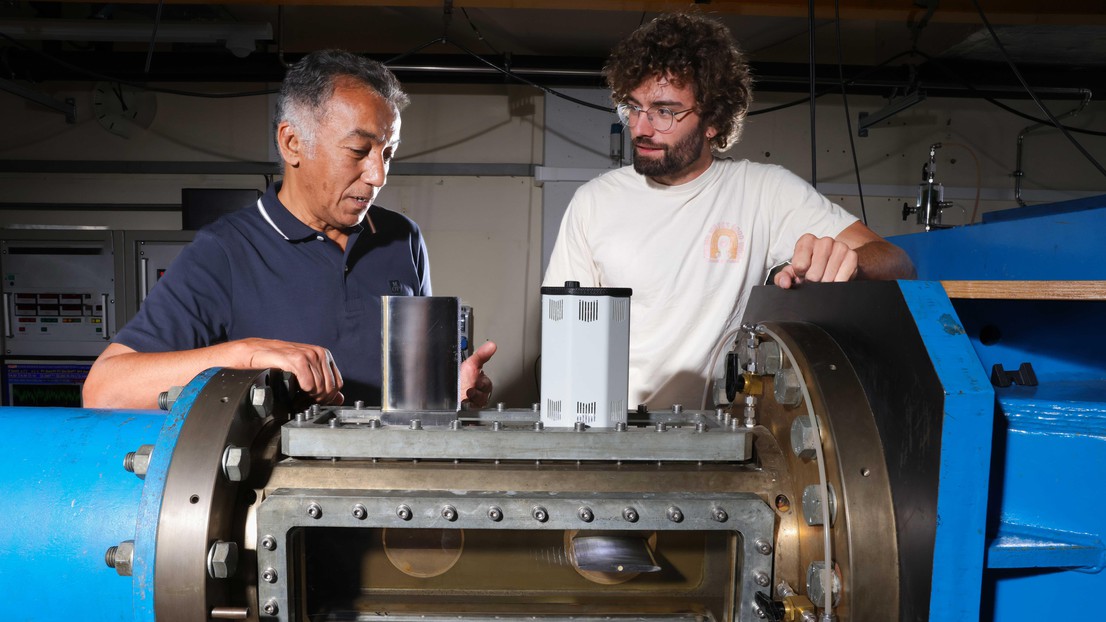

Thomas Berger (right), doctoral student, and Mohamed Farhat, thesis supervisor. 2025 EPFL/Alain Herzog - CC-BY-SA 4.0

An EPFL PhD student in mechanical engineering has developed a clever device that significantly dampens the flow-induced vibration caused by rotating parts, such as those in boat propellers, turbines and hydraulic pumps. His device can be produced with a 3D printer and has recently been patented.

It’s a classic case of beginner’s luck. Thomas Berger had just started his PhD in mechanical engineering at EPFL’s School of Engineering when he made his now-patented discovery, which has already been published. His thesis built on work he had started as a master’s student, but with the help of a 3D printer. This led to the promising technology that’s now attracting interest from investors.

Berger conducted his research at the laboratory headed by Mohamed Farhat, which studies complex fluid dynamics for applications including sailboats and hydropower turbines. “Turbines create particular challenges from both a scientific and engineering perspective,” says Farhat, who also supervised Berger’s thesis. “We’re aiming to address those challenges by running experiments on our large equipment. The biggest challenge relates to flow-induced vibration, which is a major problem for turbine designers as well as operators.” The key to Berger’s system is to eliminate the vortices that cause much of the vibration.

Powerful Kármán vortices

Vortices form when a fluid such as air or water flows over an obstacle. They’re created by such things as airplane wings, the ferries crisscrossing Lake Geneva and the Burj Khalifa skyscraper in Dubai. Once the fluid starts to flow over the obstacle at a certain velocity, alternating vortices are created in the obstacle’s wake that exert oscillating pressure on its surface, resulting in vibration. These vortices can be very strong and damage turbines or even bridges, as occurred with the Tacoma Narrows Bridge in the US in 1940. They were first identified by engineer Theodore von Kármán in 1911 and are now known as Kármán vortices.

When Gustave Eiffel built his 330-meter-high tower in Paris in 1887, Kármán vortices hadn’t yet been discovered. “The tower’s porous structure is undoubtedly what saved it,” says Farhat. “That structure mitigated the formation of strong vortices. It was a real stroke of luck!” In fact, it was this porosity that gave Berger the idea for his research.

Engineers have already devised various solutions for attenuating Kármán vortices, such as by tapering the trailing edges of turbine blades where the vortices form. These solutions have proven to be effective to varying degrees but don’t entirely do away with the problem.

Lightweight, sturdy infill structure

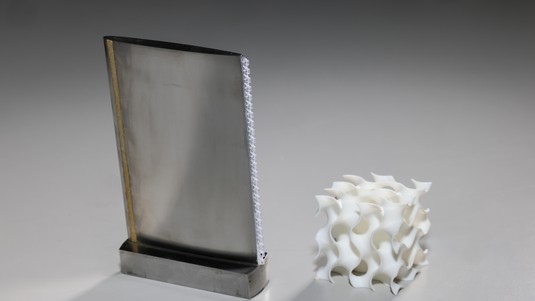

“For now, theory alone won’t let us predict the magnitude of the vibration that will be caused by a given configuration,” says Berger. That’s why he decided to use an experimental approach to find the optimal design for his vortex-reducing device. Drawing on his expertise in 3D printing, he produced and tested many different forms and materials, spending long hours in the process. He eventually found a geometrical shape that worked particularly well. “It’s a fascinating shape derived from mathematics but that also has very useful mechanical properties,” says Berger. The shape is known as a gyroid – a 3D structure made up of continuous curved surfaces that’s not only porous and tortuous but also lightweight and sturdy.

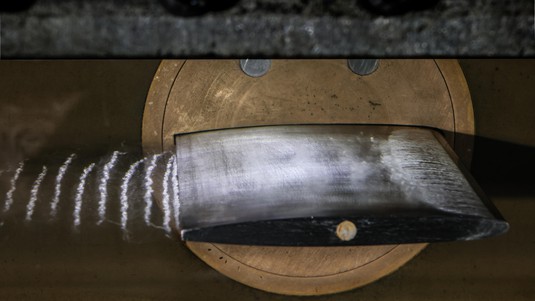

To test the gyroid, he glued the plastic-resin one he had 3D-printed onto the trailing edge of a steel blade and ran experiments in a small-scale tunnel. The result was zero vortex formation – and therefore no vortex-induced vibration. “This particular shape nips vortex formation in the bud!” says Farhat. “And it doesn’t alter the blade’s performance.” Berger made his discovery by combining mathematics with coding and 3D computer modeling.

Yet a big question remains: how does a gyroid prevent vortices from forming? “I conducted my thesis a little backwards – I started by finding the solution and now I’m working to find the scientific reason why it works,” says Berger.

Today, investors are taking an interest in his promising technology. The next step will be to test the gyroid under more complicated conditions, such as those inside turbines.

Swiss National Science Foundation and EPFL’s Technology Transfer Office

“Gyroid as a novel approach to suppress vortex shedding and mitigate induced vibration”, Berger, T. and Farhat, M., Scientific Reports 15, 25777 (2025).