Boosting biogas conversion with longer-lasting catalysts

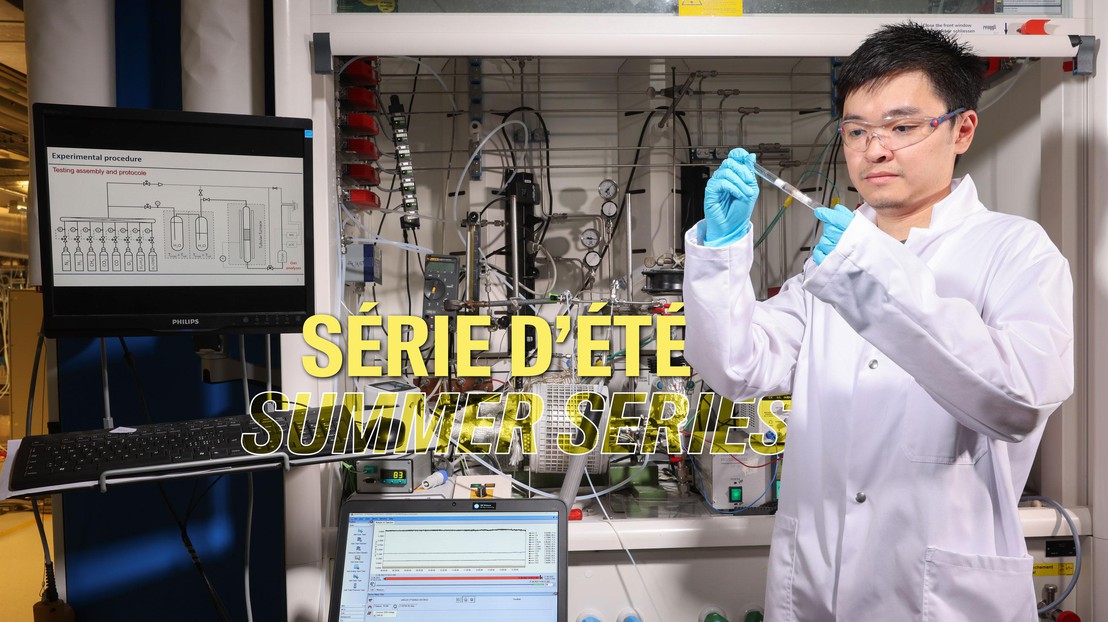

Yosua Hanria completed his Master’s project in a chemistry lab at EPFL’s Valais Wallis campus. © 2022 EPFL, Alain Herzog

SUMMER SERIES – Master’s project (9). For his Master’s project, Yosua Hanria assessed the performance and lifespan of catalysts used to convert biogas into heat and electricity. His research will support the development of new, more efficient solid oxide fuel cells.

The fermentation of organic matter such as green waste and wastewater sludge produces biogas, a renewable energy source consisting mainly of methane. With solid oxide fuel cells (SOFCs), this biogas could be converted into heat and electricity. This approach is still in the experimental stage, with further research needed before it can be brought to market.

The first step in the process involves using a catalyst to convert the biogas into two fuels: hydrogen and carbon monoxide. “The problem is that biogas contains sulfur-based compounds and other contaminants that can damage the catalysts,” says Yosua Hanria, a 24-year-old Master’s student in the chemistry and chemical engineering section at EPFL’s School of Basic Sciences. “This causes them to become less efficient and, eventually, completely unusable. For my Master’s project, I assessed the long-term performance and lifespan of these catalysts. I also looked at their tolerance to contaminants and the mechanisms by which they became deactivated.”

A vast dataset

For his research, Hanria had to learn new, practical lab skills. His experiments involved testing catalysts under different conditions – such as varying carbon dioxide and water concentrations in the air – as well as conducting mass spectrometry and gas chromatography analyses. Each experiment took between five and seven days to complete and generated vast quantities of data, which then had to be processed. “To begin with, the lab and data processing work was new to me,” explains Hanria. “I got better as things progressed, thanks to the support of my supervisor, Cédric Frantz. I’m grateful to him for making time for me.”

Promising results

At the time of writing, Hanria is still working on his Master’s project. But his early findings suggest that, for a certain type of bimetallic nickel and iron catalyst, the contamination process can be reversed: in a sulfur-free environment, they almost regain their initial state. “Sometimes, carbon is formed at the surface of the catalyst and this blocks its active sites, explains Hanria. We were able to remove almost 100% of the surface carbon by oxidation/reduction cycle.”

More generally, there are many different types of sulfur compounds or other contaminants, and they deactivate the catalysts in different ways. “One possible solution in the future would be to purify or desulfurize the biogas before we use it. It's true that we cannot remove 100% contaminants from the biogas, but at least we can purify it so that it reaches the standard of maximum allowed concentration of sulfur, which is usually 1 ppm (parts per million)”, says Hanria.

Hanria is delighted with these findings: “Even before I chose my research topic, I was interested in catalysts. I worked on them as part of my Bachelor’s degree in the Netherlands. My Master’s project has allowed me to apply what I already knew and, more importantly, to expand my understanding. And I’ve gained new lab skills in the process.” The project was also a chance for Hanria, who is from Indonesia, to explore a new part of Switzerland outside Lausanne. He conducted his research at Group of Energy Materials (GEM) lab from the School of Engineering in Valais Wallis campus, which meant a move to Sion. “The fact that I got to be part of a team was another plus,” he says. “I really enjoyed working towards the same goal as my colleagues at the lab – developing a new, more efficient class of solid oxide fuel cells.”

Partners

Hanria completed his Master’s project within the Group of Energy Materials (GEM), headed by Jan Van Herle, at EPFL’s Valais Wallis campus. His work is part of WASTE 2 WATTS (Unlocking unused bio-WASTE resources with loW cost cleAning and Thermal inTegration with Solid oxide fuel cells), a research project funded by the EU’s Horizon 2020 program.

The project was a partnership with Christoph Müller’s lab at ETH Zurich, which developed the catalysts and sent them to EPFL for analysis.