Asea Brown Boveri Ltd. (ABB) Award 2015 – Bo Jiang

© 2015 EPFL

Ceramics based technologies for high-temperature micro-reactors, EPFL thesis n° 6156 (2014)

Thesis directors: Prof. P. Muralt, Dr T. Maeder

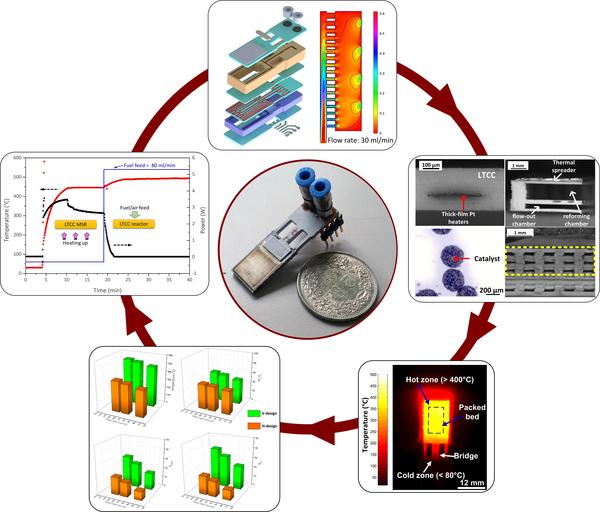

“For his important achievements in LTCC micro reactor technology and the realization of nano-catalytic micro reformers for partial oxidation of propane to feed micro solid oxide fuel cells with syngas.”

Microengineered chemical reaction systems have brought about many advantages to Nowaday’s chemical industry. It is also showing great potential for an on-board hydrogen production process that is required in fuel cells for local electricity generation. However, the harsh operating conditions, the needs of highly functional integrations and the economic constrains of the device production hinder the utilizations of polymer-/metal-based manufacturing means as well as semiconductor microfabrication methods.

Therefore, this thesis has proposed a novel ceramic fabrication route, a combination of low temperature co-fired ceramic (LTCC) and thick-film (TFT) technologies, for developing high-temperature microreactors in producing hydrogen on board micro fuel cells. The presented mm-scaled LTCC microreactors have produced high yields of hydrogen in a thermally self-operating manner above 500°C, achieving an overall power density of 1322 W·L-1. The LTCC structuration process accomplished in the above-mentioned development has alleviated the manufacturing issues of LTCC microfluidic devices and extended their microreactor applications. Moreover, the developed glass-based microreactors have been a good showcase to show how well the thick-film packaging and assembly can be applied for prototyping multi-functional high-temperature (> 500°C) microreactors in the study of chemical kinetics and process controls. Last, a high-temperature thick-film silver die-attaching solution was proposed for integrating microsystems with mismatched thermal expansion coefficients, e.g. silicon and LTCC.