Advances in track maintenance

Rail inspection software

Track maintenance can now be better optimized, thanks to more precise analysis techniques and software development.

With the increasing number of trains, often running at higher speeds, rail tracks on some segments of railway networks are put to a greater stress than ever. The two main effects of this stress are rail wear and rail fatigue. Rail wear is the deterioration of railhead profile, and side or head wear. Fatigue refers to internal fatigue defects, splits, and surface defects.

While often occurring concurrently, it is important to note that rail wear and fatigue is not uniform. Depending on the location on the track (curves, straight lines) and traffic, either rail wear or fatigue will dominate. But these two deterioration processes are linked, as one mechanism can affect the other. For example, surface deterioration may lead to a structural weakening. Assessing the state of a railway track is a complex task, for which the relationships between these two mechanisms have to be understood and calculated.

Rail maintenance is an expensive work due to the size of the infrastructure, and requires careful planning in order to minimize the impact of work on passenger and rail traffic. With cost constraints and the increase of traffic, the ability to plan rail replacement is more important than ever.

New inspection technology provides railways with more accurate information about rail condition, and enables more specific work on the most damaged segments. These new software tools precisely map defects, counts their number, measures the degree of rail wear, and the rate at which this deterioration occurs.

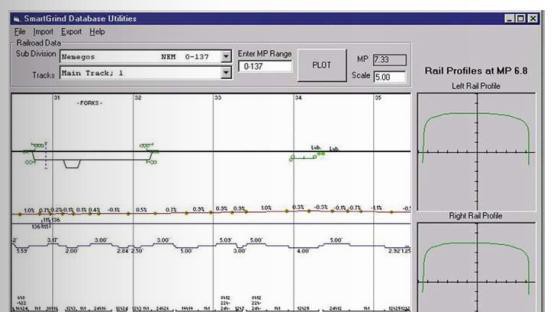

This data is then used by specific software models, allowing better maintenance planning and minimizing cost. Rail management software includes: rail relay planning software for planning and scheduling of rail replacement, rail lubrication monitoring software, rail grinding management software to control rail surface and rail test management software to monitor rail fatigue. Rail is analyzed by segments of a length suited to the track condition, and algorithms are then used to forecast defect growth rate. This data is then used together with tonnage to calculate the rail condition forecast, allowing precise rail replacement.

Software is also used to conduct life-extending operation on rails, such as grinding – an effective operation to correct rail surface and profile – for which grinding degree and pattern are calculated segment-by-segment.

With the help of these new tools, maintenance of bigger and more used than ever railway networks can be better optimized, saving money and minimizing the impact of maintenance work.

LINKS

A Newcastle University's NewRail Centre for Railway Research presentation on wheel-rail interaction at Innotrans 2010 : Wheel-rail interaction (2.7Mb PDF)

SOURCES

International Railway Journal, November 2010