Actively reducing noise by ionizing air

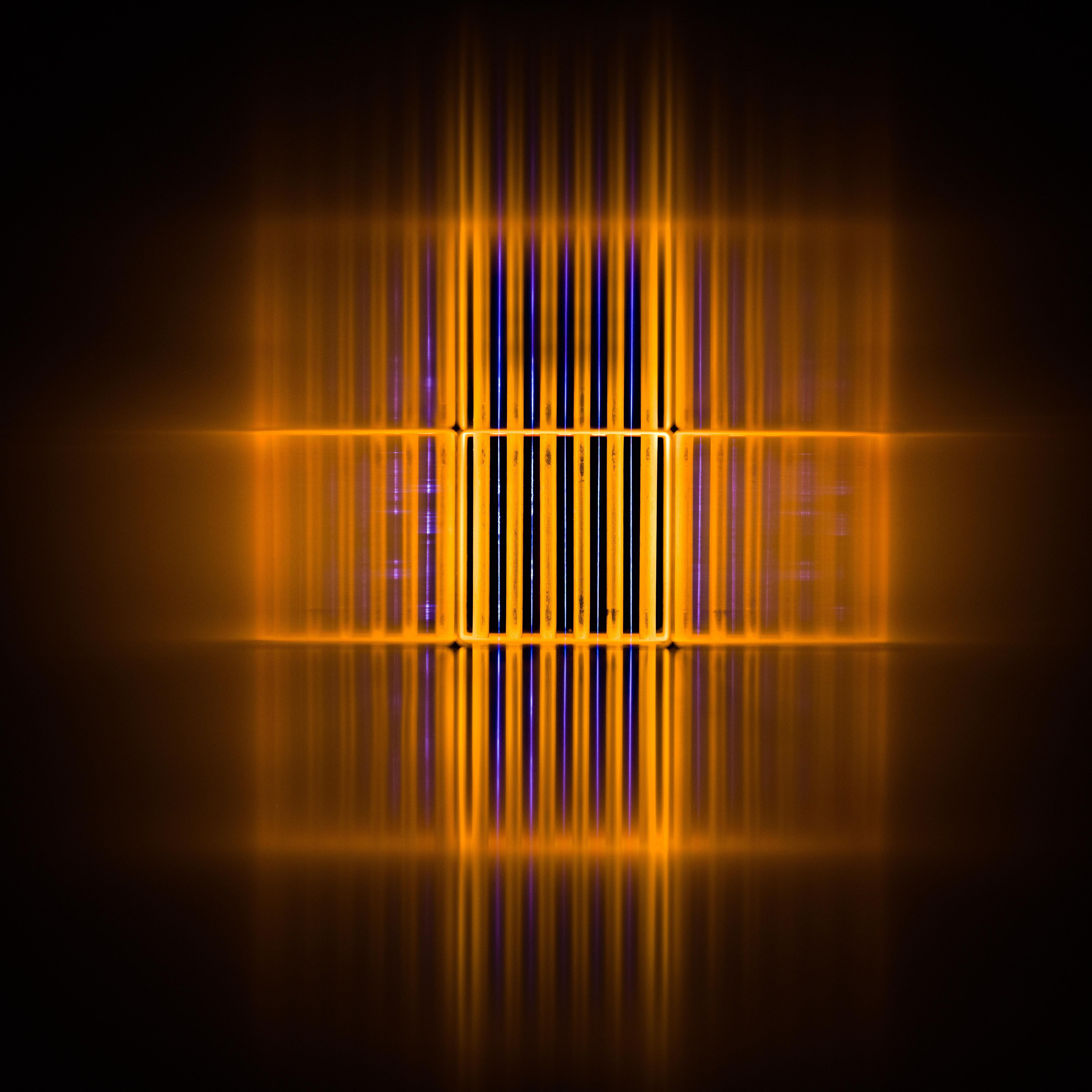

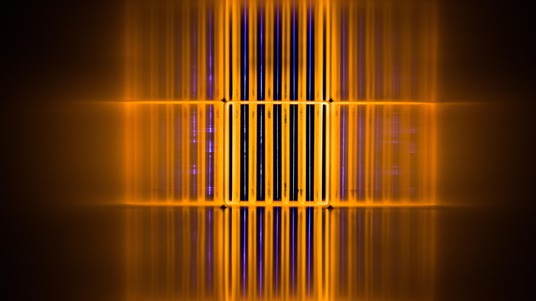

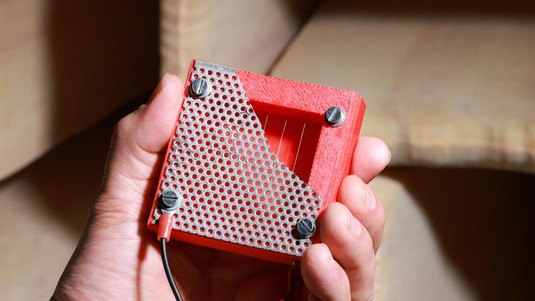

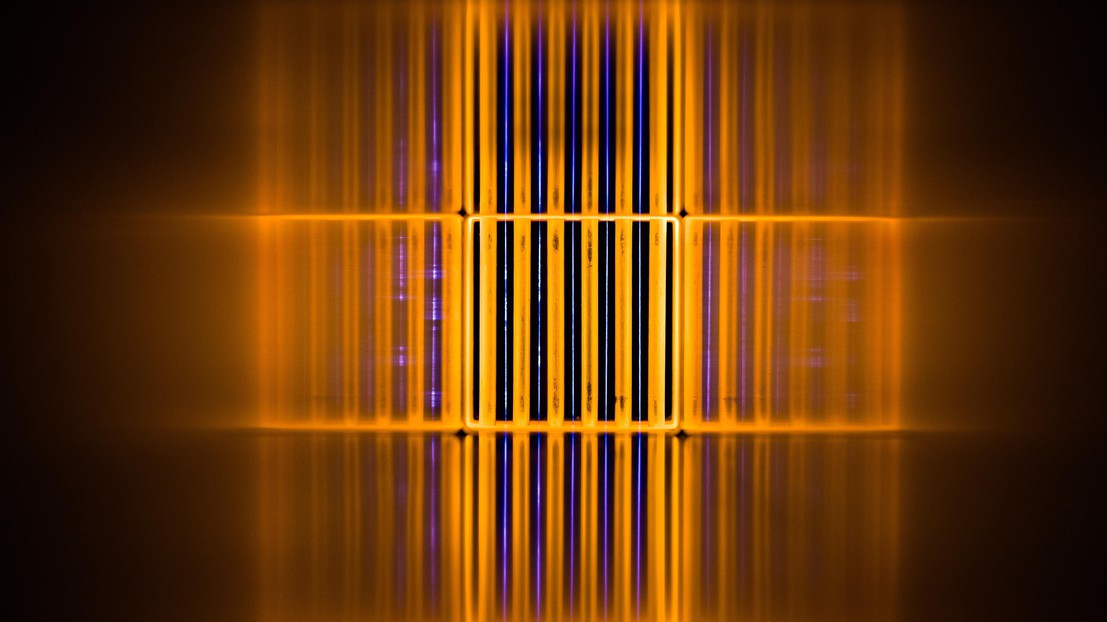

Plasma can be used to reduce noise. Credit: EPFL /LTS2 /Stanislav Sergeev & Mathias Delahaye

EPFL scientists show that a thin layer of plasma, created by ionizing air, could be promising as an active sound absorber, with applications in noise control and room acoustics.

Did you know that wires can be used to ionize air to make a loudspeaker? Simply put, it’s possible to generate sound by creating an electric field in a set of parallel wires, aka a plasma transducer, strong enough to ionize the air particles. The charged ions are then accelerated along the magnetic field lines, pushing the residual non-ionized air in a way to produce sound.

If a loudspeaker can generate sound, it can also absorb it.

While this plasma loudspeaker concept is not new, EPFL's School of Engineering scientists went ahead and built a demonstration of the plasma transducer, with the aim to study noise reduction. They came up with a new concept, what they call the active “plasmacoustic metalayer” that can be controlled to cancel out noise. Their results are published in Nature Communications.

The scientists were intrigued by the idea of using plasma to reduce noise, since it gets rid of one of the most important aspects of conventional loudspeakers: the membrane. Loudspeakers equipped with membranes, like the ones in your car or at home, are some of the most studied solution for active noise reduction. It’s active because the membrane can be controlled to cancel out different sounds, as opposed to a wall that does the job passively.

The problem with using the conventional loudspeaker as a sound absorber is that its membrane limits the frequency range of operation. For sound absorption, the membrane behaves mechanically, vibrating to cancel out the sound waves in the air. The fact that the membrane is relatively heavy, i.e. the inertia of the membrane, limits its ability to interact efficiently with fast changing sounds or at high frequencies.

“We wanted to reduce the effect of the membrane as much as possible, since it’s heavy. But what can be as light as air? The air itself,”explains Stanislav Sergeev, postdoc at EPFL’s Acoustic Group and first author. “We first ionize the thin layer of air between the electrodes that we call a plasmacoustic metalayer. The same air particles, now electrically charged, can instantaneously respond to external electrical field commands and effectively interact with sound vibrations in the air around the device to cancel them out.”

Sergeev continues, “As expected, the communication between the electrical control system of the plasma and the acoustic environment is much faster than with a membrane.”

Not only is the plasma efficient at high frequencies, but it is also versatile since it can be tuned to work at low frequencies as well. Indeed, the scientists show that the dynamics of thin layers of air plasma can be controlled to interact with sound over deep-subwavelength distances, to actively respond to noise and cancel it out over a broad bandwidth. The fact that their device is active is key, since passive noise reduction technologies are limited in the band of frequencies that can be controlled.

The plasma absorber is also more compact that most conventional solutions. Exploiting the unique physics of plasmacoustic metalayers, the scientists experimentally demonstrate perfect sound absorption: “100% of the incoming sound intensity is absorbed by the metalayer and nothing is reflected back,” says EPFL’s Acoustic Group’s senior scientist Hervé Lissek. They also show tunable acoustic reflection from several Hz to the kHz range, with transparent plasma layers of thicknesses down to only a thousandth of a given wavelength, much smaller than conventional noise reduction solutions.

To give an idea of how much more compact the plasma absorber is, consider a low, audible sound frequency of 20 Hz, where the sonic wavelength is 17m meters long. The plasma layer would only need to be 17 mm thick to absorb the noise, whereas most conventional noise reduction solutions, like absorbing walls, would need to be at least 4 m thick which often limits its feasibility.

“The most fantastic aspect in this concept is that, unlike conventional sound absorbers relying on porous bulk materials or resonant structures, our concept is somehow ethereal. We have unveiled a completely new mechanism of sound absorption, that can be made as thin and light as possible, opening new frontiers in terms of noise control where space and weight matter, especially at low frequencies” says Hervé Lissek.

EPFL has partnered with Sonexos SA, a Swiss-based audio technology company, to develop cutting-edge active sound absorbers that use the plasmacoustic metalayer concept. Together, they aim to provide novel and efficient solutions for reducing noise in a wide range of applications, including the automotive, consumer, commercial, and industrial sectors.

“This strategic collaboration leverages EPFL's expertise in material science and acoustics, as well as Sonexos' proven track record in delivering high-performance audio solutions,” explains Mark Donaldson, CEO and Founder of Sonexos.

Sergeev, S., Fleury, R. & Lissek, H. Ultrabroadband sound control with deep-subwavelength plasmacoustic metalayers. Nat Commun 14, 2874 (2023). https://doi.org/10.1038/s41467-023-38522-5