A waffle-mold for improving Grätzel cells

A new process, developed and refined at Stanford University, and based on work performed by Michael Grätzel at EPFL, will result in improvements in the efficiency of dye-sensitized solar cells.This method could also enable reductions in manufacturing costs.

Scientists are looking for ways to use every single ray of sunshine available. To be able to respond to the continually increasing demands for electrical energy, while fossil-based resources are slowly dwindling, researchers are busy trying to leverage the most generous energy source of all – the sun! Interestingly, each second of sunshine supplies the Earth with as much energy as human beings consume in the form of electricity over 15 months.

Today, the market for solar panels is finally taking off. But not as quickly as all that. The main reasons are, of course, the considerable investment required to buy modules, but also the fact that the current obtained is significantly more expensive than fossil-based or nuclear electricity. This is why it’s important to concentrate on identifying cheaper technologies than silicon panels, which dominate the market.

Twenty years ago, the research of EPFL Professor Michael Grätzel paved the way for a completely new process that imitates the principle at work in plant photosynthesis. The basic idea is to create an interaction between a solution containing pigments and two electrodes. Exposure to light then effects an exchange of electrons that can provide current to a power grid.

However, the commercial development of this promising technology is hampered by two obstacles. The performance of these sensors is at present mediocre, with only 8% of solar energy currently retrievable using solid-electrolyte Grätzel cells, compared with nearly 40% (in the laboratory) using the latest silicon modules. Moreover, the pigments deteriorate when exposed to the sun’s rays, and are no longer functional after seven years’ use.

At Stanford University in California, a team led by Mike McGehee has just published – in the journal Advanced Energy Materials – the results of the research they conducted in partnership with Michael Grätzel’s team. The objective of this work was to improve the performance of the cells using a relatively simple method, so that the cost is kept in check.

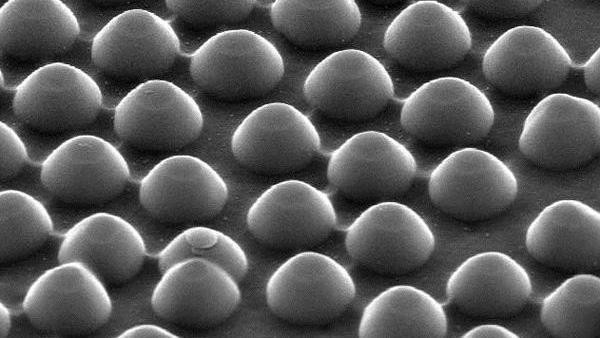

To succeed in this goal, the researchers are relying on “plasmonics”. This technology enables them to leverage the electronic “waves” that are produced when a metal and a light source interact. They have developed a kind of “waffle-mold” which is covered with silicon hemispheres of nanoscopic dimensions – each square millimeter contains more than 10 million of them! The scientists use this mold to “print” a thin layer of titanium oxide and colored pigments. This layer is then covered with a silver varnish that acts as an electrode. Within the layer of colored titanium, the light penetrates the cells and comes into contact with the silvered “domes” that have formed in the small holes. This has the effect of sending it once more through the photo-sensitive material, where it will meet more pigments. In addition, these domes, struck by the photons, may be the reason for the so-called “plasmonic waves”, from which energy can also be retrieved.

(On this pictures, solar rays are coming from below. Those who make it through the dye-sensitized titanium layer hit the silver nanodomes (left) or create a plasmonic wave (right). Source: I-Kang Ding / Stanford)

By thus optimizing the amount of light used by the sensor, Mike McGehee’s team hopes to reach a performance of 15% in these types of cells. They are also reflecting on possible solutions to extend their lifetime to 10 years. As a consequence, confirms McGehee: “We believe that we can reduce the price of the cells to less than 0.5 dollars per watt”. This is lower than the prices demanded by industry today (around 0.7 dollars per watt), and also avoids having to use the amorphous silicon normally used in thin-layer sensors.