A solution to perovskite solar cell scalability problems

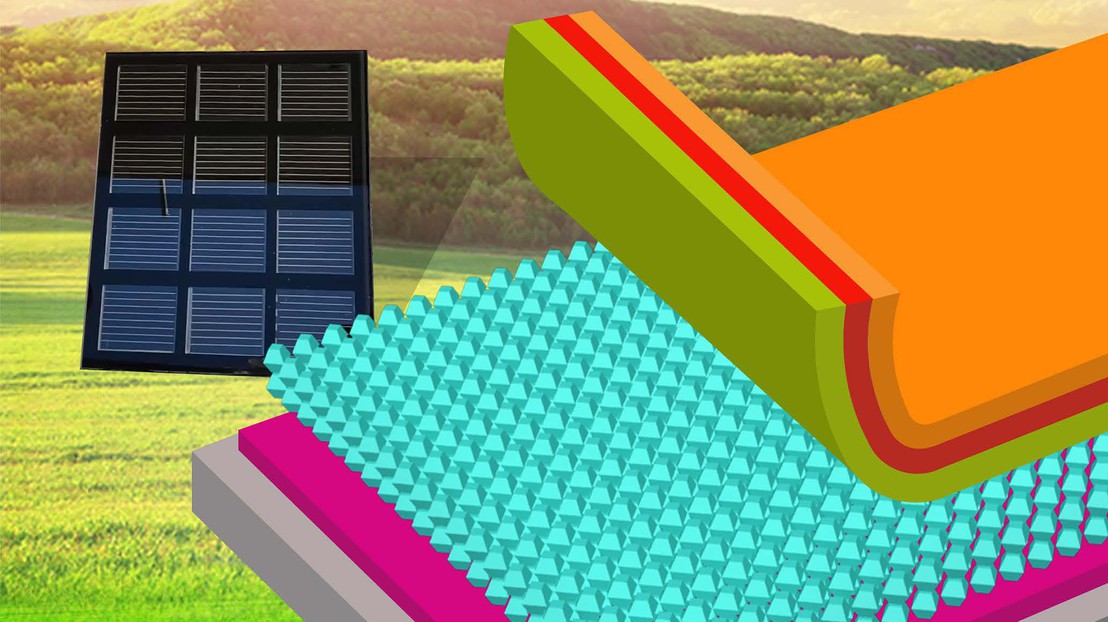

Credit: 2022 EPFL/ M.K. Nazeeruddin - CC-BY-SA 4.0

Scientists at EPFL have found a way to overcome power loss and the manufacturing complexity of scaling up perovskite solar cells.

Perovskites are hybrid materials made from metal halides and organic compounds. They have attracted a lot of interest in the field of solar energy because of their light-harvesting capacities combined with a low cost of manufacturing, making them prime candidates for overtake the market from their silicon counterparts. Perovskites also show great potential in a range of applications that include LED lights, lasers, and photodetectors.

One of the obstacles on the way to commercializing perovskite solar cells is that scaling them up results to losses in power-conversion efficiency and operational stability. This is due to natural defects in the perovskite molecular structure, which interferes with the flow of electrons. This results in “resistive loss” – a power loss due to resistance. In addition, the processes required to achieve high-quality large-area perovskite films are quite complex.

In a new study, scientists led by Mohammad Nazeeruddin at EPFL have found a way to overcome the scaling up problems of perovskites. The scientists have developed an easy solvothermal method that can produce single-crystalline titanium dioxide rhombohedral nanoparticles that can be used to build a perovskite film.

The new structure features a lower amount of “lattice” mismatches, referring to the “ladder-like” structure of the titanium dioxide nanoparticles. This translates into a lower number of defects, which ensures better electron flow throughout with lower power loss.

Testing the new nanoparticle-based, small-size solar cells, the scientists achieved a power-conversion efficiency of 24.05% and a fill factor (a measure of actual obtainable power) of 84.7%. The cells also maintain about 90% of their initial performance after continuous operation for 1400 hours.

The scientists also fabricated large-area cells, which certified an efficiency of 22.72% with an active area of nearly 24 cm2. This “represents the highest efficiency modules with the lowest loss in efficiency when scaling up,” conclude the authors.

Other contributors

- North China Electric Power University

- Luxembourg Institute of Science and Technology (LIST)

- University of Luxembourg

- Chinese Academy of Sciences (CAS)

- Xi'an Jiaotong University

- Hebei University

- Istituto CNR di Scienze e Tecnologie Chimiche “Giulio Natta” (CNR-SCITEC)

- University of Perugia

- Istituto Italiano di Tecnologia

- Prince Mohammad Bin Fahd University

- Huazhong University of Science and Technology

- University of Würzburg

- Westlake University

- Huaqiao University

- EPFL Laboratory of Organometallic and Medicinal Chemistry

- City University of Hong Kong

Valais Energy Demonstrators Fund

National Key R&D Program of China

111 Project (Plan 111)

National Natural Science Foundation of China

Deutsche Forschungsgemeinschaft (DFG)

Swiss National Science Foundation (SNSF)

Luxembourg Fonds National de la Recherche

Yong Ding, Bin Ding, Hiroyuki Kanda, Onovbaramwen Jennifer Usiobo, Thibaut Gallet, Zhenhai Yang, Yan Liu, Hao Huang, Jiang Sheng, Cheng Liu, Yi Yang, Valentin Ianis Emmanuel Queloz, Xianfu Zhang, Jean-Nicolas Audinot, Alex Redinger, Wei Dang, Edoardo Mosconic, Wen Luo, Filippo De Angelis, Mingkui Wang, Patrick Dörflinger, Melina Armer, Valentin Schmid, Rui Wang, Keith G. Brooks, Jihuai Wu, Vladimir Dyakonov, Guanjun Yang, Songyuan Dai, Paul J. Dyson, Mohammad Khaja Nazeeruddin. Single-crystalline TiO2 Nanoparticles for Stable and Efficient Perovskite Modules. Nature Nanotechnology 21 April 2022. DOI: 10.1038/s41565-022-01108-1