A new motor for the watch of tomorrow

© 2011 LAI-EPFL

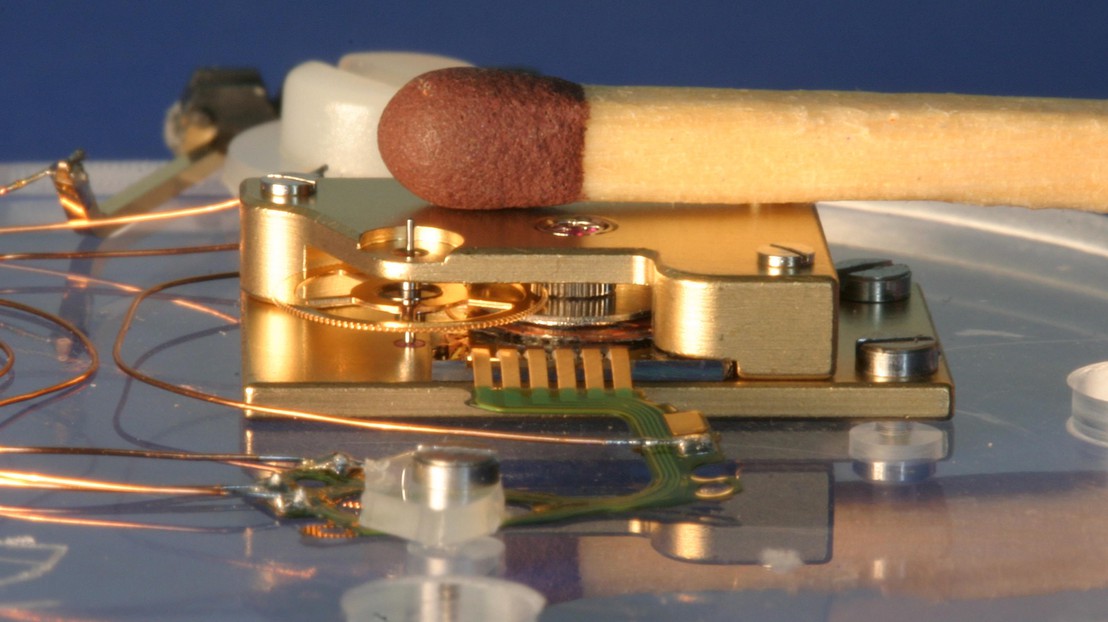

An electromagnetic three-phase motor, invented by EPFL’s Integrated Actuators Laboratory, will enable the watchmaking industry to build watches that are three times more efficient and that can include more applications.

Tomorrow’s wristwatches will be more efficient. Their batteries will last much longer. And in addition to giving the time, they might offer additional functions such as a telephone, a compass or other kinds of energy-consuming applications. EPFL’s Integrated Actuators Laboratory (LAI), in Neuchatel, has made a major step in this direction with the invention of a new kind of motor whose energy output is three times greater than traditional motors. It will thus satisfy the requirements and developments of the watchmaking industry.

To manufacture micro-electronic microsystems, known as MEMS, engineers typically call upon the principles of electrostatics. The LAI scientists, however, are proposing an electromagnetic drive system. Using a fixed magnet and three phases instead of a single phase, this novel device has more than once required its inventors to overcome formidable challenges…

“To obtain a good motor, you need a minimum of two or three phases, that is to say, two or three copper coils,” explains Yves Perriard, head of LAI. “However, these coils take up room, and thus we were obliged to invent a new configuration and geometry for the motor. And most of all, they’re very expensive to make using traditional methods, which haven’t changed since the 1970s.”

Clean room fabrication

The researchers thus opted for a new fabrication process. The method had to be conducted in a clean room and was complicated to set up – a total of 24 operations had to be defined. But it was worth it, because the method makes it possible to manufacture certain components at very low cost. The stators, for example, fixed parts of the motor, are engraved on silicon plates, which means that a large quantity of them can be made simultaneously.

They also encountered another difficulty: with three phases, the command electronics had to be redesigned. “To tell time adequately, the motor must be able to locate the rotor, or the rotating part, at any point in time,” explains Perriard. “However, it would be very expensive to equip the motor with sensors to do this. We are thus trying to come up with solutions from signal processing techniques that use the motor’s voltage and current.” It’s a tiny device, but it’s filled to the brim with ideas and inventions…