A new method to make thin-films for cheap solar energy conversion

© 2015 EPFL

Semiconducting materials with high crystallinity and purity constitute the top-performing solar energy conversion devices, but are still too expensive. Our group has now used 2-D layered semiconductors to develop a method to fabricate high quality thin films for solar application that is both simple and inexpensive.

Two-dimensional (2-D) “layered” materials, which famously include graphene, have crystal structures that allow them to form atomically-thin films that have superior electronic properties making them promising for use in various hi-tech devices. One class of semiconducting 2-D materials, the transition metal dichalcogenides or “TMD”s, are promising candidates for high-efficiency solar energy conversion. However, it is notoriously difficult to fabricate thin films of 2-D TMDs over the large areas required to harvest solar energy on a practical scale. Current fabrication methods are too expensive to commercialize, which prevents their widespread application. Our group (LIMNO) has now developed a simple method to fabricate high-quality thin films of 2-D layered TMDs at low cost and with good efficiency towards solar-to-fuel energy conversion. The work is published in Nature Communications.

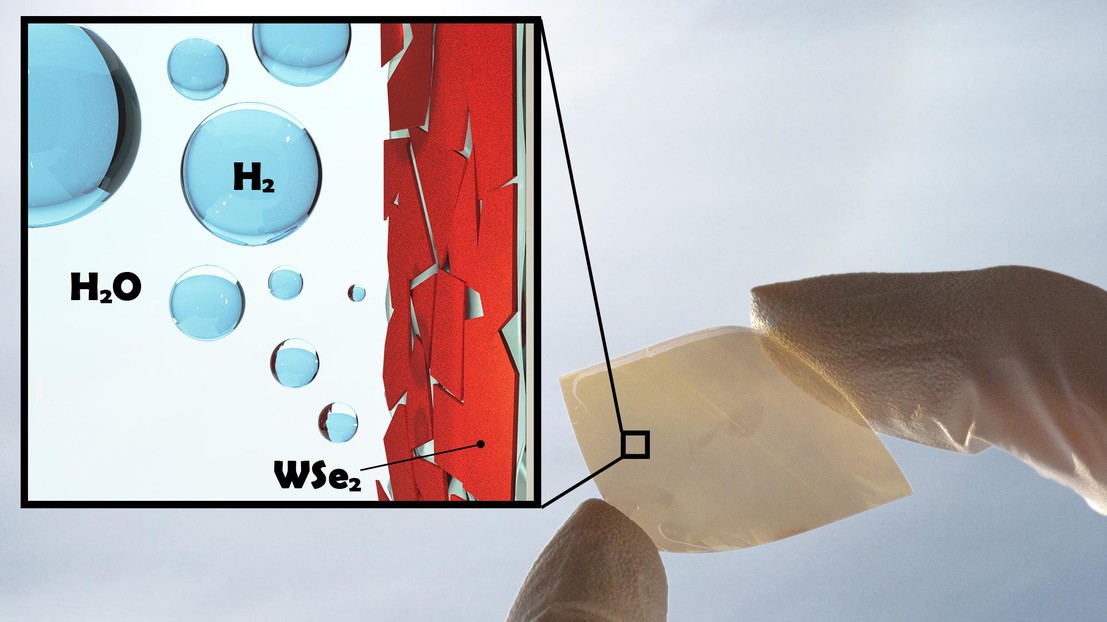

In this study, we investigated the semiconducting TMD material called tungsten diselenide (WSe2). In the form of a single crystal, this material has previously shown great promise for both photovoltaic energy conversion and for photoelectrochemical water-splitting, converting up to 14% of solar energy directly into hydrogen fuel. Moreover it is known for its high stability. A challenge with this and other TMD materials is to find inexpensive ways to make thin-films while maintaining good electronic performance. Xiaoyun Yu in our group developed a simple and cheap liquid-based method for creating thin films with layered materials by exploiting their ability to be “exfoliated” into 2-D flakes and by subsequently using a clever oil-on-water effect to self-assemble the film. The idea is to first form a homogeneous dispersion of the 2-D flakes and then inject them at the interface between two non-mixing liquids, which acts as a “rolling-pin” to evenly spread out the flakes and induce the formation of a high-quality film.

To first produce a homogeneous dispersion of tungsten diselenide, Xiaoyun added a common solvent to WSe2 powder and exfoliated the material into 2-D flakes using sound vibrations (“sonication”). Followed by the addition of special surfactants, a homogeneous and surprisingly stable dispersion resulted. This method was previously developed by our group (published in 2014) and has been shown to produce very stable 2-D flake dispersions, which do not precipitate even after many months. However when the solvent was removed during film deposition, the flakes tended to clump and restack unevenly, causing poor electronic performance.

To overcome this drawback the tungsten diselenide dispersion was injected at the interface between two immiscible liquids: ethylene glycol and hexane. The “oil-on-water” effect between these two liquids creates an interface that is the key to the film formation. The surface tension at the interface drives the flakes to spread out evenly, minimizing clumping and restacking, and allowing the edge-to-edge self-assembly of the flakes into a continuous thin film.

Next, the two liquids were carefully removed, and the thin film was transferred to an inexpensive conductive plastic substrate. After being dried at 150°C, the scientists had a homogeneous thin film of WeS2.

We next used simple electronic measurements to show that the conductivity of the WeS2 film prepared by the liquid-liquid self-assembly technique was superior to that of a film prepared with the same flakes by a traditional solution-based deposition method. In addition microscopy images showed a drastic improvement of the flake alignment in the thin film, with no clumping or restacking of the flakes observed.

Finally, Mathieu Prevot tested the solar-to-hydrogen conversion efficiency of the WSe2 thin films. The results, even at this early stage, indicate solar energy conversion efficiencies of around 1%, which is a vast improvement over films prepared by other solution-based methods. Given the demonstrated stability of these materials and this new comparatively easy thin-film deposition method, which is suitable for rapid and large-area roll-to-roll processing, the results represent an important advance towards economical solar-to-fuel energy conversion.