A new dimension for cell culture

© 2012 Alain Herzog

The system developed by QGel allows for new tests of anti-cancer medication and novel experimentation in tissue engineering and regenerative medicine.

Cancer cells and stem cells can now be cultivated in 3 dimensions to serve in various experiments to great advantage for researchers. This matrix, commercialized by the start-up QGel, which is based in the scientific park at Ecublens, offers the cells a similar environment to a living organism and is adaptable to the needs of the researcher. The new company received the Vigier Prize on Thursday, which comes with a cash sum of 100,000 francs.

The basic substance resembles a gel, but it is in fact a biocompatible and biodegradable polymer to which different bioactive components such as collagen or growth factors can be added. This substance, produced in Jura, is presented as a small flask containing dehydrated gel to which water must be added. One can then reproduce the extracellular matrix in which cells live inside organisms. Contrary to the traditional Petri dish, where cells form a simple layer, studies have shown that with this substance, the cells grow and assimilate just as they do in their natural environment.

Cultivating cells in such an environment facilitates the study of potential medications in conditions similar to cells in vivo. For example, we know that when a tumor grows, its oxygen levels decrease. The matrix developed by the start-up allows one to reproduce such phenomena among others, which make the efficiency of the active substance vary, thus yielding more realistic conditions. The growing longevity of the cells cultivated in vitro inside the gel also allows the researcher to add the medication being tested at different intervals in order to study its impact according to the moment when it is used. This allows for the exclusion of superfluous molecules during the very first phases of the test.

It’s the extracellular matrix that confers the specific properties to the tissues. The secret to the welfare of cells lies in the creation of a custom-built and ideal environment. Growth factors, proteins, peptides or other components can be added to the gel. In the case of stem cells, for instance, it is possible to add molecules that indicate which tissue, nerve or vessel they must form and which direction they must grow.

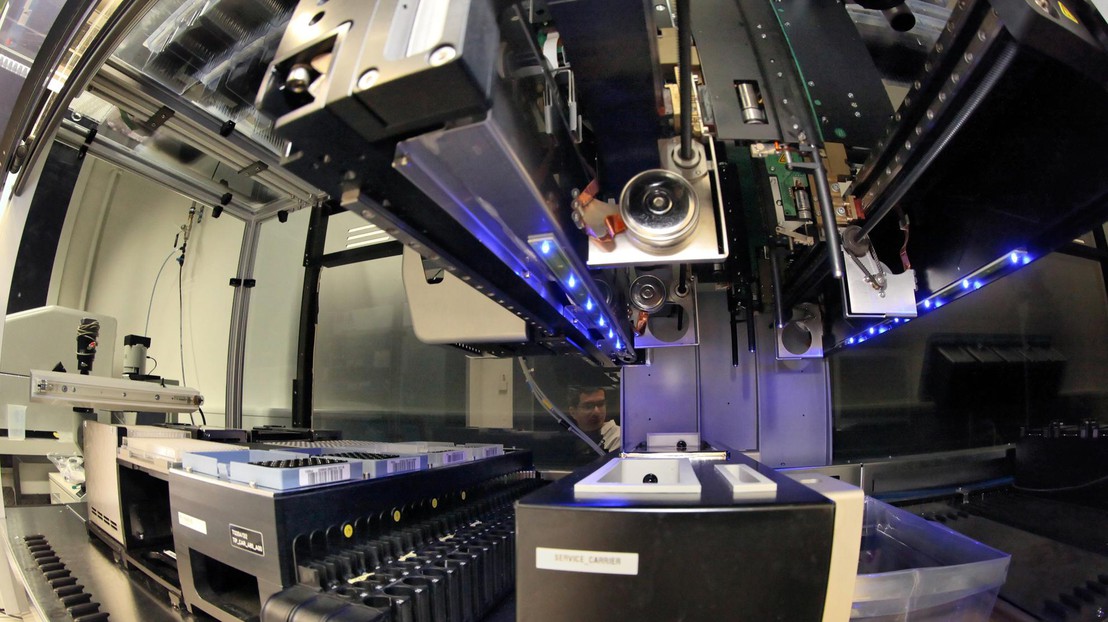

“Research in regenerative medicine and tissue engineering, as well as the development of new medication, should gain in speed and reliability,” explains Matthias Lütolf, professor of stem cell bioengineering and co-founder of the start-up with Colin Sactuary, CEO. A robot’s capacity to perform quick tests on a big scale has been adapted to the utilization of this gel for a more efficient and precise outcome. The cosmetic industry has even shown interest in this product for testing the toxicity of certain substances – especially since in vivo tests will be prohibited in Europe as of 2013.

The product commercialized by QGel is the result of a long and laborious effort guided by Jeff Hubbell, a professor at the Laboratory of Regenerative Medicine and bio-pharmacology at EPFL, and whose research is associated with projects at Stanford, ETHZ, University of Zurich and the California Institute of Technology. “Other research groups are developing systems to cultivate cells in three dimensions, but none of them are at the same time as stable, robot-friendly, inexpensive, identically reproducible and adaptable”, states Matthias Lütolf. Though their product is already used by many research institutes, the next aim of the start-up is to get 2 million francs to create its own laboratory, where they can custom make the gels and independently sell them to pharmaceutical groups.