A digital solution for sustainable timber construction

© 2021 EPFL

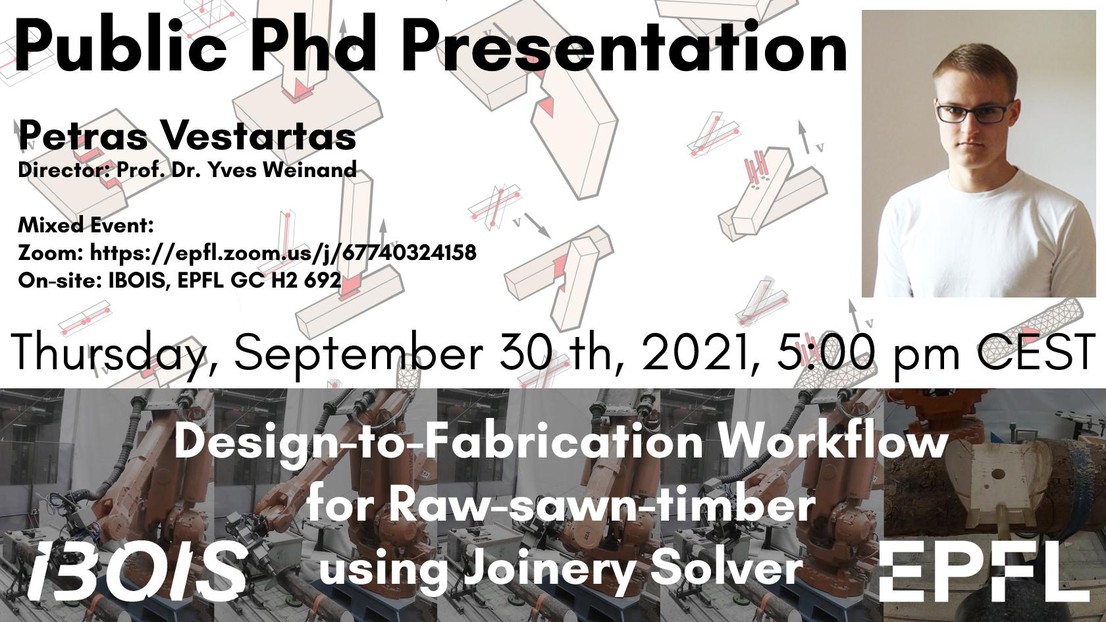

Petras Vestartas invites you to his public thesis defence which will be held on 30th September 2021 at 5:00 PM (CEST) by zoom-video and on-site conference at IBOIS, EPFL. He will be introducing a new, digital, design-to-production solution for local sustainable wood construction.

His thesis, supervised by Prof Yves Weinand, is titled: Design-to-Fabrication Workflow for Raw-Sawn-Timber using Joinery Solver. It presents a new, digital, design-to-production solution to one of the main challenges currently faced by the Swiss timber industry in mountain areas. This often results in the export of unprocessed lumber and import of finished timber products, while it would be far more sustainable and economically viable to develop new building systems for structures using local timber. Due to transportation requirements and environmental restrictions, the maximum size of timber segments in such contexts are of approximatively 5 meters, and most of the work is manual. Petras’s project connects industry and research and allows for the use of irregular timber, which is usually considered of little or no value.

The fact that construction is responsible for approximatively 40% of global CO2 emissions in developed countries, up to 50% of resource consumption, and about a third of waste further underlines the need for sustainable solutions. Timber is a renewable resource which is naturally biodegradable, and IBOIS integrated mechanical attachment techniques further facilitate the disassembly of structures by rendering unnecessary the often costly process of sorting through the material to remove metal connectors. The method proposed in this thesis allows for optimal construction with a far lighter carbon footprint.

Automation in raw wood fabrication is solidly established, but remains poorly integrated in the local timber industry. While a few large technology companies focus on raw-sawn-timber fabrication, which leads to a high-level automation in fabrication, they do not offer any architectural design methods. Architect and fabricator, in the raw wood context, are seen as two different entities. Research in architectural digital manufacturing makes it possible to design with raw timber while eliminating dependence on large centralized timber companies.

An additional problem which often arises is that projects focus on a single case study, without seeking to introduce automation in local economies. This results in the creation of small-scale semi-automated fab-lab workshops. Consequently, Petras’s research intends to revisit individual design-to-fabrication workflows for whole timber structures and propose new open-source, extendable and reusable techniques.

The system proposes a joinery algorithm which will ease the drafting process of pair-wise wood-wood connections. The joinery algorithm is based on a design modelling separation into two independent algorithms covering:

a) global architectural design

b) local automation of wood-wood connections

The algorithm must fit a number of design requirements. It needs to ensure the re-usability of the joinery methods for more than one case study, include a joinery library, allow the automatic generation of wood-wood connections, respect fabrication constraints, propose a fast collision-based graph method integrating the joinery algorithm into a common CAD modelling environment, and finally, use minimal models for fast computation.

The geometrical irregularities of raw wood require laser-scanning and robotic integration. Scanning offers novel solutions for raw wood fabrication such as point-cloud processing, marker-less alignment within a robotic setup, and calibration guidelines for laser scanners. The robotic part introduces tool-path planning algorithm to shorten fabrication file preparation. Design recommendations for machining setups are given to ensure secure, stable and accurate fabrication.

Three types of timber joinery prototypes are assembled to validate the proposed workflow: segmented timber shells, nexorades and a truss from tree forks. The modelling framework is interconnected with tool-path planning to manifest the validity of fabrication of joint geometries. All developed algorithms are open-source.

Petras’s design-to-fabrication workflow proves the possibility of detecting wood joinery types using minimal CAD models. These models do not require hard-coded parametric skills and, as a result, are usable in CAD modelling interfaces. The successful integration of the laser scanner and the robotic arm in order to generate joinery methods bridges the gap between architectural design and manufacturing, offering an efficient, sustainable and economical solution for local construction.

EPFL (École Polytechnique Fédérale de Lausanne)

Petras VESTARTAS, Design-to-Fabrication Workflow for Raw-Sawn-Timber using Joinery Solver, EPFL thesis n°8928