A design class that gives students free rein

The class, which is part of the Master of Science in Microengineering program, lets students experience the design process from start to finish.

The idea behind the Product Design & Systems Engineering class couldn’t be simpler: students have to design and build an object that serves a purpose. “That’s the only instruction we give them,” says Prof. Yves Bellouard, who heads the Galatea Lab at EPFL’s School of Engineering (STI). The class was launched in 2016 as a way to get students working as a team and experiencing the entire design process, from developing a concept to making a prototype. Over the course of three months, groups of six students carry out market research, build a prototype, deliver a presentation and write a technical report that includes a patent proposal. Each team has a maximum budget of just 500 Swiss francs. “The idea is to stimulate innovative thinking,” explains Bellouard. “This year, the teams came up with some amazing concepts, some of which have market potential.” Prof. Edoardo Charbon, who heads the Advanced Quantum Architecture Lab at STI and has taught the class alongside Bellouard since 2017, adds: “One recent project even spawned a startup.”

A pill box for the elderly

This year, two groups opted to design an automatic pill dispenser for senior citizens. “After talking to medical professionals, we learned that people over the age of 65 often take two or three pills a day,” says student Titouan Marois. “Our machine is designed to help older members of society maintain their independence.” The device, dubbed Pill It, consists of three wheels: one for the morning, a second for lunchtime and a third for the evening. Each wheel has 31 compartments – one for every day of the month. “Once the machine is filled, it dispenses the pills automatically over the course of a month,” adds Marois. “Our prototype works in a similar way to a coffee machine, since it releases the drugs into a small cup.” The dispenser is paired with a smart watch that vibrates to remind the user that it’s time to take a pill. The watch can also alert a family member if the wearer falls ill or has an accident.

Myriam Rihani’s team developed a different kind of pill dispenser called Drug Minder. “Our design uses drawers,” she says. “Each one contains a particular type of drug. The machine mixes and dispenses the right combination.”

Aquatic debris and water analysis

Other students tackled environmental issues with their designs. One group built a floating garbage can called Fluenta that uses the force of the currents to collect debris. “The structure is made from recycled materials,” says student Florian Maître. “And it’s secured to the sea or river floor with an anchor.” The design includes a hatch to stop trash from escaping from the cage. “It has to be emptied every two days,” adds student Philippine Milward.

Another team developed a robot that can collect samples at different locations in the water column. Baptized Seampler, it features a series of empty tubes that can be filled at the desired depths. “Plastic pollution is a major problem in the oceans,” says student Lara Laamari. “But before we can remove this waste, we first need to know where it’s located – and that isn’t as easy as it sounds.” The samples would then be sent to a lab, where they would be analyzed to determine if microplastics are present.

Purifying water by evaporation

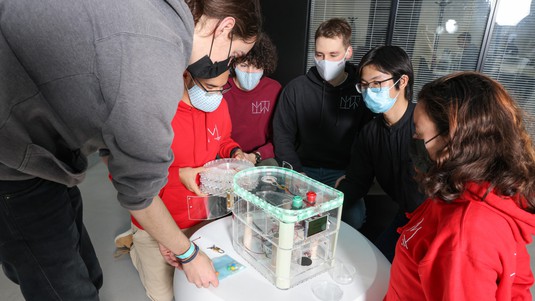

Student Costanza Baudino and her team designed a solar-powered water filtration machine. The device, named Aquacycle, purifies dirty water through a process of evaporation and condensation. “Normally, evaporating water through a filter to make it safe to drink isn’t a practical option because it takes too long,” says Baudino. “We decided to speed up the process by heating the water using solar power.” Student Leonardo Cele’ adds: “Our prototype isn’t complex in structure, but it serves a practical purpose.”

The best class

Aside from working on the technical aspects of their designs, the students also learned how to work together and divide the tasks among themselves. Some of them found the teamwork aspect challenging. “Assigning responsibilities and dividing up the workload wasn’t easy for us,” says Baudino. Other teams, like Milward and Maître’s, hit the ground running right from the start. Laamari, meanwhile, says she enjoyed being given free rein by the professors. “We could design whatever we wanted,” she explains. “We had to manage our budget and our time and decide who was going to do what. The professors and their assistants were on hand to advise and guide us.” According to Marois, it’s the best class in this Master’s program: “We didn’t gain technical knowledge, but we picked up skills in areas such as marketing and team management.” He adds that building the prototype in the workshop was his favorite part of all.