A cost-effective conversion of commercial FFF 3D printers into MEWs

© 2023 EPFL

EPFL scientists have been able to successfully convert commercially-available 3D printers, based on FFF technology, into MEW devices. This achievement has proved the possibility to significanntly reduce the budget needed to carry out MEW additive maunfacturing, still preserving the high performances related to the devices currently present on the market.

In the framework of an international collaboration between scientists from the University of Oregon (UO), the Basque Center on Materials (BCMaterials) and EPFL's School of Engineering, an open source platform to convert a standard Fused Filament Fabrication (FFF) 3D printer into a highly capable Melt Electrowriting (MEW) device has been established. The team, coordinated by Prof. Jürgen Brugger and Prof. Cristophe Moser, concerning EPFL's contribution, has been able to successfully prove the possibility to carry out high-performances MEW additive manufacturing with a relatively lower budget equipment.

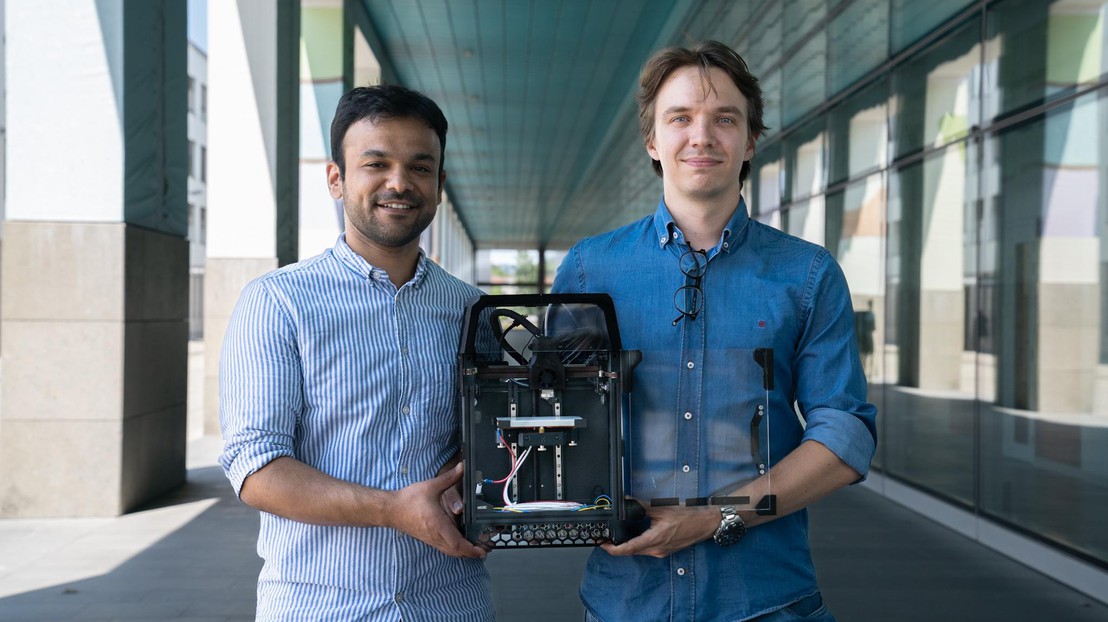

Congratulations to our colleaugues Taavet Kangur and Dr. Biranche Tandon, for having contributed to achieve such an important result, which will allow to spread the use of MEW techniques in the additive maufacturing community.

For more information, visit https://actu.epfl.ch/news/open-source-mewron-device-unleashes-new-possibilit/