A chip to measure vacuums

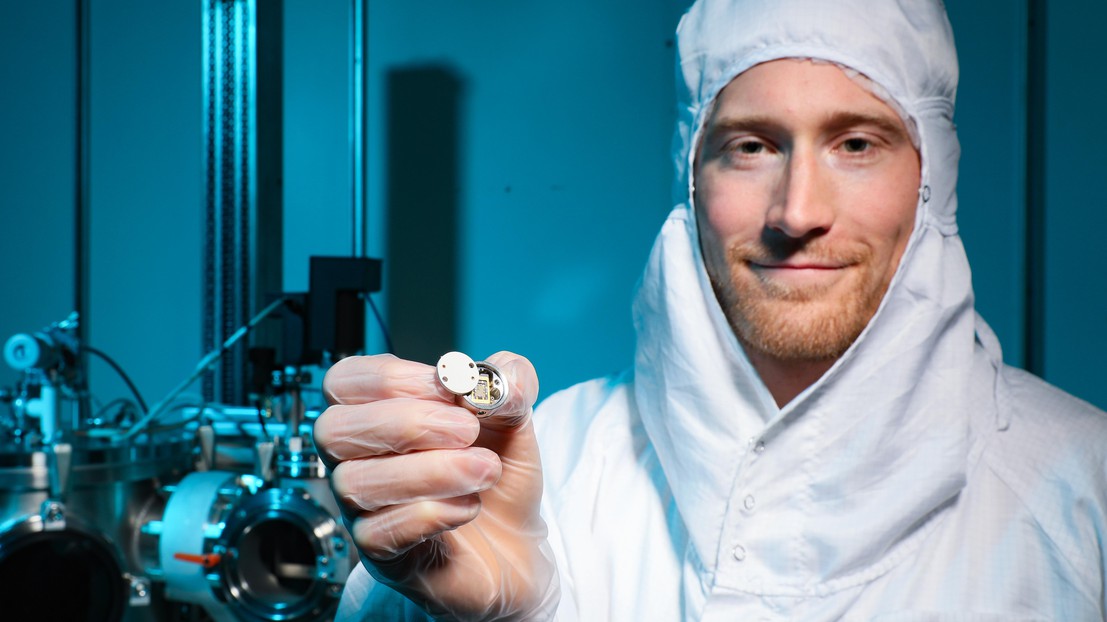

Ian Rousseau, CEO of Hexisense, brings to the market a gallium nitride-based chip that can measure vaccums © 2019 Alain Herzog

Vacuums are a vital part of the processes – such as freeze-drying – used to make and preserve countless everyday items and must be measured with precision. An EPFL spin-off, Hexisense, is bringing to market a gallium nitride-based chip that can measure the quantity of certain gas molecules cheaply and with unrivalled precision.

What do a mirror, a cup of yogurt, an electric car battery and an LED lightbulb have in common? Their production processes all require a vacuum, i.e. an environment in which gas molecules are removed. Usually, when the last drop has been poured from a bottle, the bottle is considered empty. Physically, however, it remains full of gas. When a vacuum is required, suction pumps leave a varying amount of gas depending on the process used. A vacuum is therefore assessed on the basis of pressure exerted by the number of molecules that remain in the container. This measurement is crucial for manufacturers – and an EPFL spin-off is preparing to bring to market a small chip that could make their lives easier.

An ideal tool for freeze-drying

Let’s take freeze-drying as an example. This is a technique for preserving food that maintains its color and texture and most of its nutritional qualities and flavor. It is often used when researching and producing food and medicines, and is very energy-intensive and time-consuming. Items are dried in a vacuum, and the main stumbling block is that there is no low-cost way of determining the exact moment at which the process can be stopped. This means that the machinery does more work than is necessary. The sensor developed by EPFL’s Laboratory of Advanced Semiconductors for Photonics and Electronics could overcome this drawback by indicating the remaining amount of water vapor in real time.

Let’s take freeze-drying as an example. This is a technique for preserving food that maintains its color and texture and most of its nutritional qualities and flavor. It is often used when researching and producing food and medicines, and is very energy-intensive and time-consuming. Items are dried in a vacuum, and the main stumbling block is that there is no low-cost way of determining the exact moment at which the process can be stopped. This means that the machinery does more work than is necessary. The sensor developed by EPFL’s Laboratory of Advanced Semiconductors for Photonics and Electronics could overcome this drawback by indicating the remaining amount of water vapor in real time.

Vacuum systems contain various residual gases: nitrogen, oxygen, argon, hydrogen, water vapor etc. To measure them, manufacturers currently have two options. The cheap one involves various methods to measure the total pressure of all those gases on the basis of parameters such as deformation, displacement and heat. The other, mass spectrometry, distinguishes between the gases, but cannot be used in all systems because the equipment is expensive. The small 0.4 cm2 chip developed and soon to be marketed by the EPFL spin-off aims to offer an affordable way of measuring individual gases in all vacuum systems.

Using light to unstick gas molecules

The mini-sensor harnesses two physical characteristics of its main component, gallium nitride: its reactivity to light and its status as a semiconductor. In a vacuum vessel, when gas molecules become less numerous, they move towards the walls and stick there. Gallium nitride, when exposed to a light source, repels certain gas molecules, like oxygen. So an LED is placed on the chip, which unsticks molecules from the walls. Once the light goes off, gallium nitride’s semiconductor properties allow the chip to measure how quickly gas molecules return to the walls. Specific algorithms then analyze the number of molecules on the surface along with the partial pressure of each gas. These tiny chips boast excellent efficiency: for example, they can detect oxygen within nitrogen at a concentration of less than 0.5%.

An all-purpose chip that is heat- and shock-resistant

These all-purpose chips are heat-resistant up to 250°C and do not contain any microelectromechanical systems, which means they can withstand mechanical vibrations and shocks. In addition, unlike low-pressure ionization-based vacuum gauges, these sensors do not produce ionized particles or magnetic fields that could affect certain technical equipment. These advantages mean that the new-generation chips are highly versatile, making life easier for their users because all they need to do is place the chips within their pressure systems in order to get the data they need.

Production underway

The two inventors, Ian Rousseau and Pirouz Sohi, supported by various startup programs such as Bridge – the joint accelerator set up by the Swiss National Science Foundation and Innosuisse – EPFL Innogrant, Enable and Venture Kick, are now starting to produce these chips. Hexisense, the resultant spin-off company, aims to commercially develop and produce the sensors, from design to characterization, production and packaging.