3D-printed insoles measure sole pressure directly in the shoe

© Marco Binelli, ETH Zurich

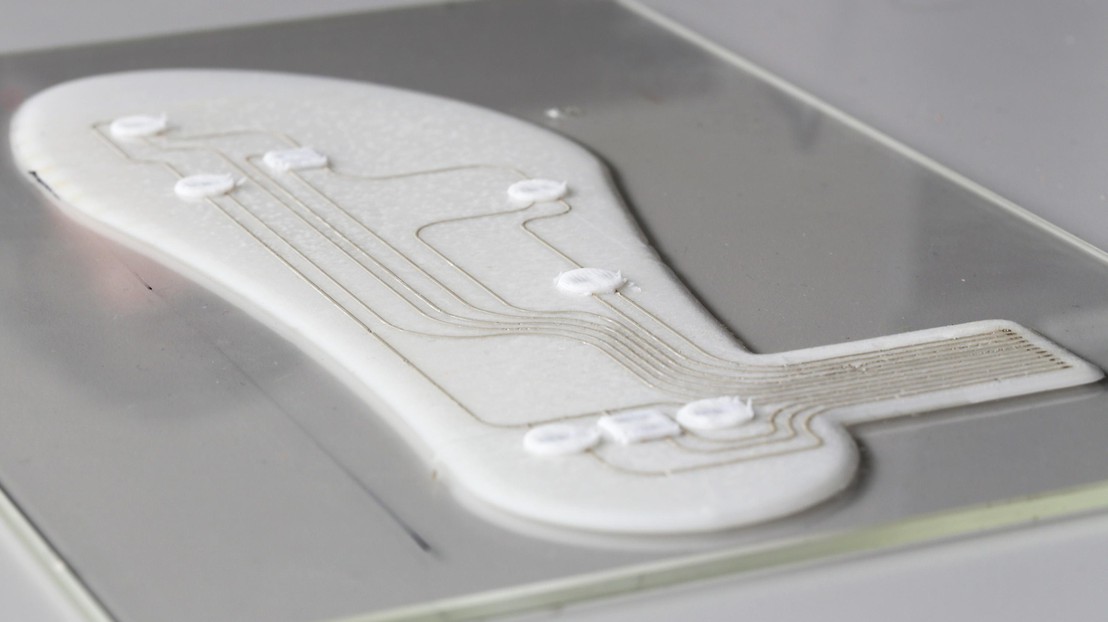

Researchers at ETH Zurich, Empa, and EPFL are developing a 3D-printed insole with integrated sensors that allows the pressure of the sole to be measured in the shoe during activity. This helps athletes or patients to determine performance and therapy progress.

In elite sports, fractions of a second sometimes make the difference between victory and defeat. To optimize their performance, athletes use custom-made insoles. But people with musculoskeletal pain also turn to insoles to combat their discomfort.

Before specialists can accurately fit such insoles, they must first create a pressure profile of the feet. To this end, athletes or patients have to walk barefoot over pressure-sensitive mats, where they leave their individual footprints. Based on this pressure profile, orthopedists then create customized insoles by hand. The problem with this approach is that optimizations and adjustments take time. Another disadvantage is that the pressure-sensitive mats allow measurements only in a confined space, but not during workouts or outdoor activities.

Now, in a project coordinated by Danick Briand of the Soft Transducers Laboratory in the School of Engineering, researchers from ETH Zurich, Empa, and EPFL have used 3D printing to produce a customized insole with integrated sensors that can measure sole pressure directly in the shoe during activity. The invention was recently featured in the journal Scientific Reports.

“You can tell from the pressure patterns detected whether someone is walking, running, climbing stairs, or carrying a heavy load on their back – in which case the pressure shifts more to the heel,” explains co-project leader Gilberto Siqueira, Senior Assistant at Empa and at ETH Complex Materials Laboratory. This makes tedious mat tests a thing of the past.

One device, multiple inks

The insoles are produced in just one step – including the integrated sensors and conductors – using a single 3D printer called an extruder. The researchers use various inks developed specifically for this application. The materials scientists used a mixture of silicone and cellulose nanoparticles as the basis for the insole. They used piezo components, which convert mechanical pressure into electrical signals, as sensors for measuring normal and shear forces. They also built an interface into the sole for reading out the generated data.

Tests showed that the additively manufactured insole works well. “With data analysis, we can actually identify different activities based on which sensors responded, and how strong that response was,” Siqueira says.

At the moment, Siqueira and his colleagues still need a cable connection to read out the data; to this end, they have installed a contact on the side of the insole. One of the next development steps, he says, will be to create a wireless connection.

Although Siqueira believes there is strong market potential for their product, especially in elite sports, his team hasn’t yet taken any steps towards commercialization. In the future, 3D-printed insoles with integrated sensors could be used by athletes or in physiotherapy, for example to measure training or therapy progress. Based on such measurement data, training plans can then be adjusted and permanent shoe insoles with different hard and soft zones can be produced using 3D printing.

Researchers from ETH Zurich, Empa, and EPFL were involved in the development of the insole. EPFL researcher Danick Briand coordinated the project, and his group supplied the sensors, while the ETH researchers developed the inks, while the ETH and Empa researchers developed the inks and the printing platform. Also involved in the project were the Lausanne University Hospital (CHUV) and orthopedics company Numo. The project was funded by the ETH Domain’s Advanced Manufacturing Strategic Focus Areas program.

Binelli, M.R., van Dommelen, R., Nagel, Y. et al. Digital manufacturing of personalised footwear with embedded sensors. Sci Rep 13, 1962 (2023). https://doi.org/10.1038/s41598-023-29261-0