Swissto12 conquering space with 3D printing

© 2015 Alain Herzog

Satellite communications could be streamlined by light and inexpensive antennas that have been developed by SWISSto12. This EPFL spin-off has just signed a major contract with the European Space Agency to develop its metal-plated polymer design.

It’s no secret: when it comes to space launches, less mass generally translates into lower cost. It is no surprise, then, that the antennas developed by SWISSto12, a start-up housed at EPFL’s Innovation Park, have attracted the attention of the European Space Agency (ESA). SWISSto12’s antennas are ten times lighter and significantly less expensive than the metal antennas currently in use.

The non-stop growth in data transfer – driven by TVs, telephones, surveillance, GPS and the internet – requires ever-more bandwidth in satellite communications. To expand this capacity, increasingly high wave frequencies are being used: the microwave threshold has been crossed. Yet high frequencies become more and more difficult to control, and this is where the quality and shape of antennas play a crucial role.

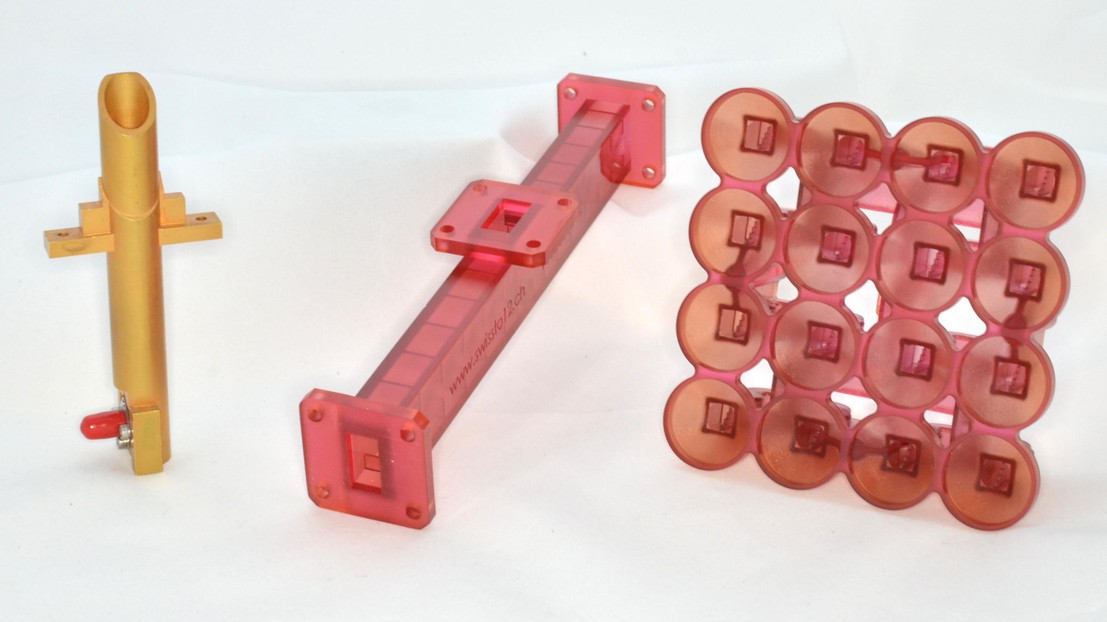

The ground-breaking system developed by SWISSto12 can take many forms. It looks like a plastic sculpture of a few tens of centimeters high with evenly spaced holes in it. It contains a network of narrow channels that is the result of an extremely precise design and production process. To achieve this level of precision, it is easier and significantly less expensive to print an object in three dimensions than it is to assemble a number of little machined parts. SWISSto12’s antennas are made with polymers and then coated in metal using a patented process. It is an entirely new approach. “When we talk to customers about our products, it’s almost as if we were talking science fiction at first. But when they see the antennas and the test results, they start to come around,” said Emile De Rijk with a laugh. De Rijk is the CEO of the company, which is collaborating with EPFL’s Laboratory of Electromagnetics and Acoustics.

Feather-light antennas

Thanks to this innovation, these antennas weigh only a tenth as much as metal ones. Considering that a large geostationary satellite can carry up to 100kg of this type of equipment and that the launch cost is generally between 10,000 and 20,000 francs per kilo, the calculations are quick: remarkable cost savings are at stake. Particularly since the new technologies currently set to take over – stratospheric drones – will have the same weight concern.

This contract is part of an ESA programme aimed at developing high-tech products for space that could also have commercial uses, especially in the connectivity-on-the-move market. This contract is the ESA’s first in this area and has the support of the Swiss Space Office (the Swiss delegation to the ESA). The eventual goal is to contribute to high-speed internet solutions via satellite that will allow passengers using various modes of transport – planes, trains, automobiles and boats – to have better internet access during their travels.

Airplanes will save on kerosene

Thanks to their precision and design, high-frequency antennas could even reduce the size of the domes above the airplane fuselage. “Improved aerodynamics also mean saving on kerosene,” said De Rijk.

The start-up, founded four years ago, recently became a member of the Swiss Space Center in order to encourage synergies with the Swiss space community. It is now planning a new round of fund-raising.