Shrinking reactors down to size

EPFL’s Lioubov Kiwi and her group are developing new reactors by using micro- et nano-technologies.

Pharmaceuticals, energy, perfumes, polymers – all are industrially produced via chemical reactions. To carry out reactions, one needs reactors (vessels of different types and sizes ) to mix the various reagents and some catalysts, while controlling the pressure, temperature, and other parameters.

Usually, industrial chemical reactions take place in large vessels, producing big quantities of substances. The use of these vast reactors has many drawbacks. For example, it’s difficult to obtain uniform mixing at constant temperatures, and one has to stop the process regularly to empty the reactor. Moreover, chemical reactions are often successfully performed in small reactors in the laboratory, but many problems arise in achieving the same results when the production is scaled-up in industry. This is like preparation of a dish for two people doesn’t involve too much difficulty, but preparing the same dish for 100 people is a different matter!

The EPFL’s Group of Chemical Reaction Engineering (GGRC) headed by Lioubov Kiwi has studied the use of microreactors for many years. They produce the required substances in tiny pipes, quickly enabling a highly uniform mixing that is perfectly controlled in terms of temperature (which also avoids the risk of explosion), often without the use of solvents, and in a continuous flow. For example, the reagents could be injected through two separate pipes in a Y-shaped system. They react when they meet, and the resulting product comes out through the third pipe. Detractors say that only insufficient quantities can be produced, but these reactors can be used by thousands in parallel. The products created in these microreactors are purer and therefore higher quality, as the process avoids the manufacturing of undesirable by-products inherent in large reactors.

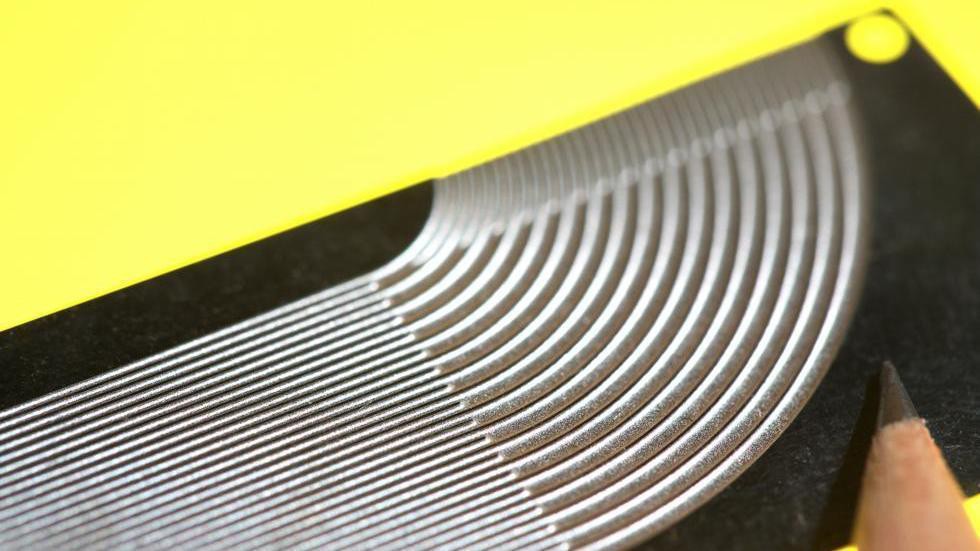

Professor Kiwi and her team have received 2.4 million Swiss francs from the European Union to develop these microreactors. 650 thousand Swiss francs have been allocated to a new project, POLYCAT, which started up on November 15. The goal is to combine the advantages of a microreactor and a nano-catalyst. “To reach our objective, we employ micro- and nano-technologies together”, explains Lioubov Kiwi. The concept/process consists of the deposition on the micro-reactor walls of a polymer thin film that anchors the catalyst nanoparticles (gold, palladium etc.). These nanoparticles remain exposed to the reacting liquids or gases while being firmly fixed to the walls of the micro-capillaries.

Such a catalytic reactor could become a reality within two to three years, significantly improving the performance of industrial chemical reactions in terms of their quality, as well as their environmental and safety-related impact.