Sensors pave the way to using energy from the stars

© 2011 EPFL

The international ITER project is setting out to store the energy of stars in a reactor. To meet this challenge, scientists must be able to measure the properties of matter in fusion. A team at EPFL has just successfully tested some sensors that are necessary for the ITER prototype.

The scientists’ ambition is to keep matter with a temperature of several million degrees contained here on Earth. Using stars as a model, they want to produce energy by fusing hydrogen to form helium. The main difficulty consists in maintaining matter in this state – called plasma – while avoiding any contact with the installations, which would melt them. To achieve this, the ITER reactor project will contain the percolating energy of the plasma using magnetic fields. This is why it is necessary first to establish its electromagnetic properties. The physicists therefore need measuring instruments appropriate to this extreme environment. Taking part in the project, a team from the Center for Research in Plasma Physics (CRPP) led by Jo Lister, has successfully conducted tests of two sensors that will be installed in the reactor prototype.

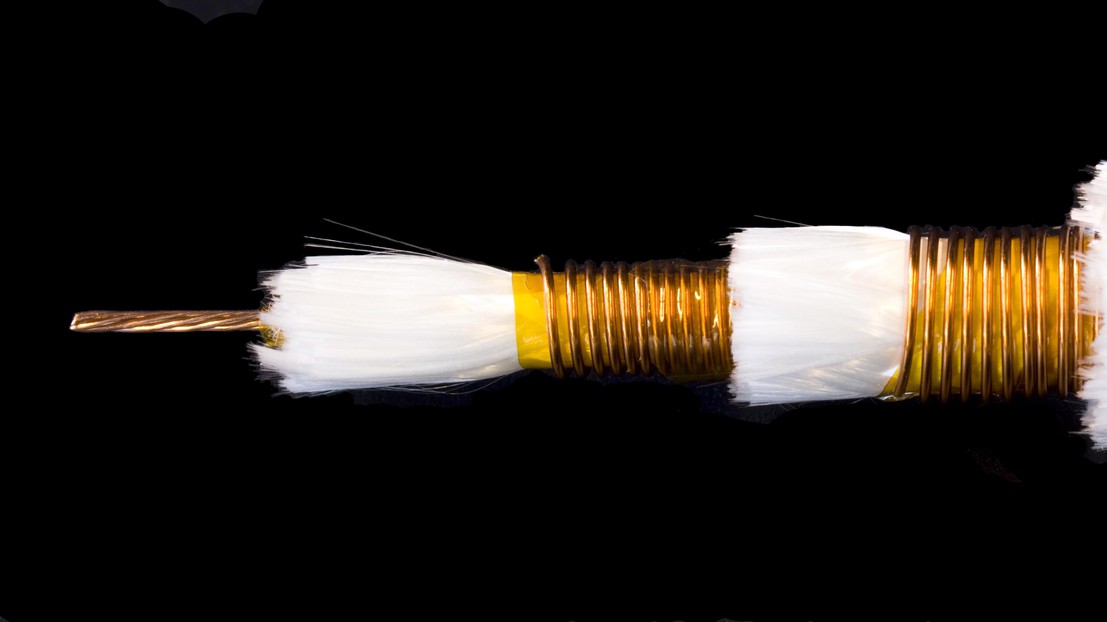

To accomplish this feat – measuring a current of nearly 15 million amps without making any contact with the plasma at several million degrees – the scientists will surround the reactor chamber with electric coils. They will then measure their electrical tension, which is generated even at a distance by the plasma. These measurements will then make it possible to work out the properties of the plasma, such as its position and shape.

The sensors developed for this research must guarantee a high level of accuracy to allow the theories to be validated and the plasma to be monitored. In the ITER reactor, where the plasma is confined in a space in the shape of a rubber ring of 6 meters in diameter, the measurements must detect variations in the position of the plasma to within a millimeter. In the case of the magnetic field, its orientation must be known with an angle to an accuracy of half a degree, hence the second measuring instrument that was tested.

First steps towards a prototype

“The overview is important”, explains Jo Lister. This is why the research work is essential although the aim is to develop this technology for industrial deployment. The tests are being carried out in collaboration with the French Atomic Energy Commission (CEA) and the Italian National Research Council (CNR). These results, the product of 18 months of collaboration, will be published shortly and will enable the installation of sensors on the reactor to be validated by 2013.