Making industrial plasma safer

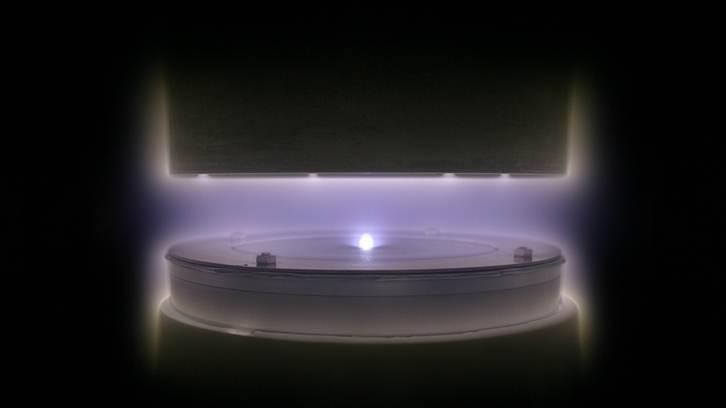

A plasmoid © 2013 EPFL

EPFL scientists have uncovered the physics behind the formation of plasmoids – funnel-like, high-energy plasmas that can severely damage industrial plasma reactors, causing millions in repairs and lost productivity in plasma technologies like those used to make display screens and even food containers.

Plasma is the most common state of matter in the universe, found mostly in stars and the intergalactic space. However, plasma is widely used in industry to serve a surprising number of everyday applications, including solar cells, fluorescent lights, display screens, and even air-tight food packaging. Despite its enormous benefits, exploiting the properties of plasma can be difficult and can cause problems for manufacturers. One common problem is the formation of plasmoids – localized intense plasma that can spontaneously ignite and damage the plasma reactor, incurring high repair costs and manufacturing downtime. Publishing in Plasma Sources Science and Technology, EPFL scientists have discovered how plasmoids form and propagate, and offer possible solutions for industrial applications.

Plasma is essentially a hot gas whose molecules become ionized, that is, they turn into charged particles. Though abundant in the universe, on earth natural plasma is limited to lightning bolts, flames, and auroras. However, artificially maintaining plasma is difficult because plasmas readily react with molecules of other materials, and therefore require a vacuum. At the same time, it is exactly this high reactivity that makes plasmas so useful in industrial manufacturing applications, such as metallurgy, plasma spraying and coating, microelectronics etching, metal cutting and welding and even in aerospace engineering.

However, plasma technologies are not without problems. One of them involves the specialized reactors that are used to create and confine plasmas. Given the high temperatures involved in plasma generation, it easy to cause damage to the reactor’s structure. One common problem is the formation of plasmoids, which are intense localized plasmas that can ignite spontaneously and, if not stopped immediately, can melt and destroy reactor components. Plasmoid damage can put a reactor out of commission for a long time, requiring expensive repairs and costly losses in production.

A team led by Christoph Hollenstein at EPFL’s Center for Plasma Physics Research (CRPP) has now shown that plasmoids work like a funnel for an intense electrical current. In effect, when a plasmoid forms, it transports electrons through to the reverse side of the reactor’s grid, which is meant to contain the plasma. The study focused on industrial-type plasmas, which are generated with a power supply that runs at a radio frequency (13.56 MHz). The researchers found that plasmoids are actually sustained by this radio-frequency power supply, forming a positive plasma potential on both sides of the reactor’s grid. It is this funneling of electrical current that can cause strong heating of the plasmoid and subsequent damage to the reactor’s components.

The research team used a small plasma reactor specifically designed to generate plasmoids that could be observed. By creating several such plasmoids, the scientists were able to study what causes a plasmoid and how it propagates to the point where multiple plasmoids can appear, risking severe damage to the reactor’s structure. The study also demonstrated that the ignition of plasmoids is confined in a small point, meaning that the density of the electrical current that passes through the ‘funnel’ is very high. The authors suggest that this is why the occurring plasmoid can cause such damage.

"By discovering the physics behind plasmoid formation, we can propose strategies for plasma industry to suppress them”, says author Alan Howling. By regulating the plasmoid-forming mechanisms of their reactors, manufacturers can minimize or prevent plasmoids altogether.