How will Swiss radioactive waste be disposed of?

© 2011 creative commons Wikipédia

If Switzerland does indeed abandon nuclear energy within the time-frame announced by the Swiss Confederation, the question of the burial and disposal of the accumulated waste needs to be addressed. EPFL’s Laboratory of Soil Mechanics has been working on this issue over the last 10 years. Apart from its geo-mechanical expertise, the LMS creates the materials – and develops the tools for – the verification of systems of multiple barriers, capable of containing the radioactivity for five hundred to a thousand years.

To generate electricity, Switzerland has been using nuclear energy for nearly 40 years, and its five nuclear power stations provide about 38% of the electricity required. It’s the second most important source of electricity in Switzerland after hydro-electricity. However, the Swiss government recently decided on a gradual phasing-out of atomic energy, and the existing nuclear power stations will be decommissioned over the next twenty years, with the last remaining installation scheduled to be closed down in 2034. The federal law on nuclear energy stipulates that nuclear waste must be managed in Switzerland: more specifically, it states that the waste should be stored in depots located in deep strata, which is considered to be the most appropriate solution for Switzerland. So how should we prepare for the safe and definitive storage of our nuclear waste? For several years, the Laboratory of Soil Mechanics (LMS) has been contributing to research into the identification of the best place for its storage. In parallel, the LMS is also researching into various tools for the evaluation of multi-barrier systems. We asked Professor Lyesse Laloui, the director of the LMS, about the current state of affairs from a scientific and critical viewpoint.

How does Switzerland currently handle its nuclear waste?

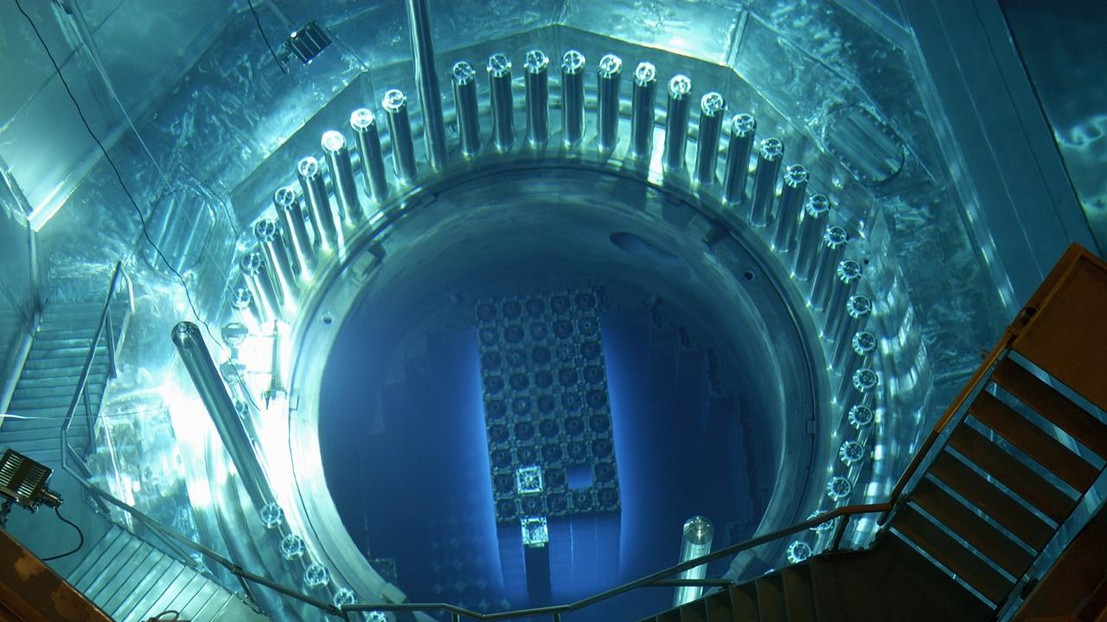

Since the moratorium voted by the parliament in 2006, Swiss nuclear waste is no longer sent to France and Germany: instead, the 8000 m3 of waste is being cooled in enormous pools in Würenlingen in the canton of Aargau. This is only a temporary measure, since it is planned to bury the waste permanently in deep geological strata.

Are there different types of waste?

Yes, there are in fact two categories of waste:

• Waste that is low- to medium-level radioactive, whose lifespan is short – from a few dozen years to 300 years maximum. It comes not only from nuclear power stations, but also from medical uses, industry and research establishments. We have a lot of expertise in handling this waste.

• Highly radioactive waste, which will take several million or even billions of years to become inactive. We call this “final waste” – that which is at the end of the re-processing chain, and which is not possible to refine further. This is the type that we have to store definitively.

Which scenarios are favored in Switzerland?

Storage in deep geological strata: Several sites are being evaluated in Switzerland. Once the location has been chosen, it will be necessary to create a network of tunnels one kilometer deep: the waste will then be stored there.

Vitrification of the waste: This means mixing the waste with a glass matrix. It’s estimated that glass can withstand heat, irradiation and degradation through contact with water for about 300,000 years. Each glass cylinder is placed in a steel container: this constitutes a kind of “package” of glass waste 8 meters long and weighing about two tons.

The fixing of vitrified waste in sodium bentonite: this clay expands in volume when it is exposed to moisture. It can absorb several times its mass in water, and – when injected in the storage tunnels – it expands and fills the spaces between the cylinder and the rock. Each country is carrying out research in different directions. The Swiss strategy is not to be able to access the waste once it has been sealed in the bentonite.

What is the nature of your research work? Where is it carried out? And what are the risks?

Our research is focused on the physical phenomena that interact in the course of the life of buried waste. We have to ensure a maximum level of security with regard to both natural and man-made barriers.

In choosing the site, we’re evidently concerned with its stability.

Specifically, we concentrate on the connected thermo-hydro-mechanical-chemical processes. Heat is an important factor: the waste generates temperature of the order of 150 degrees over hundreds of years. How do we ensure that the radio-necleotides won’t damage the vitrification?

When we consider the environment below ground, water is everywhere: we regard it as the biggest threat. It can damage the steel lining by corrosion, which would have two consequences: the formation of gas – at the LMS we are trying to understand how this gas circulates in the tunnels – and the release of radioactive particles that could be transported by underground circulation.

To minimize risk, it’s therefore essential to develop performant evaluation tools for the various barriers designed to seal off the waste, and to test and improve the materials that would be used in the process. We are developing scientific research on materials and also scenarios for the optimization of technical solutions.

We have analyzed the impact of environmental elements on the behavior of geo-structures. To do this, we worked with the Mont-Terri underground laboratory in the Jura region of Switzerland. The laboratory consists of a network of tunnels located 300 meters deep, that are cut into a type of rock that can be found just about everywhere in the country. Because of this, the data gathered can be extrapolated.

We are also carrying out research on the enhancement of the properties of bentonite, which is the final protection and sealing barrier before the rock, and are currently in the middle of trials in the underground laboratory at Grimsel. We blasted bentonite on rock walls, and then after the drying process was completed, we took some samples, which are currently being analyzed at EPFL. We need to determine its level of hermeticity, its mechanical properties, its expansion potential and its density, and use this data to develop the best possible material. We’re testing various compositions of bentonite, subjected to heating at 120° in an underground laboratory in Sweden. Our own laboratory is involved in international research, and I’m currently coordinating a European proposal as part of the 7th framework program, as well as organizing an international conference on this subject, to be held at EPFL from February 1 to 3, 2012.