Bacteria-based method turns wood into pharmaceuticals

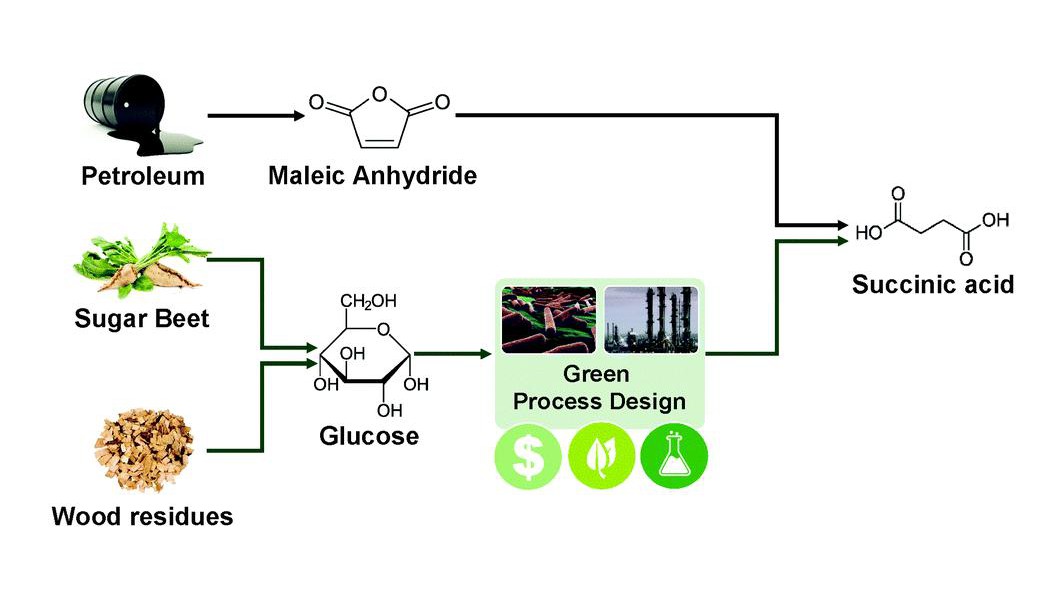

Petrochemical production via maleic anhydride versus alternative production from renewable resources via glucose to succininc acid © Energy & Environmental Science

Scientists at EPFL, Chalmers University and ETH Zurich have developed a greener and cheaper method for making succinic acid, which is key for transitioning onto renewable energy.

Bio-succinic acid has gained much interest recently as a potential bio-derived platform chemical, and is already widely used in the manufacturing of detergents and surfactants, as an ion chelator, and in the food and pharmaceuticals industry. However, we still lack sustainable and standardized methods for producing enough bio-succinic acid to meet our needs. Scientists from EPFL, Chalmers University, and ETH Zurich have developed a bacteria-based, efficient and environmentally friendly method for making bio-succinic acid for greener pharmaceuticals. The work is published in Energy & Environmental Science.

Among the products that we use in daily life, pharmaceuticals have one the most adverse effects on the environment. To address this, the research teams involved in this study aimed to develop a way of producing green pharmaceuticals, which are environmentally beneficial and cheaper to produce from abandoned wood in Switzerland. As such, the scientists worked under the framework of the Swiss National Research Program “Resource Wood”.

The researchers combined metabolic engineering with the most mature technologies to produce bio-succinic acid from sugar beet and lignocellulosic residues. The lab of Vassily Hatzimanikatis at EPFL identified the properties of a metabolic-engineered E. coli strain that can produce high amounts of bio-succinic acid from glucose originating from wood waste. Meanwhile, the lab of Stavros Papadokonstantakis at Chalmers built an industrial production process for the engineered bacteria, and Konrad Hungerbühler’s team at ETH Zurich evaluated the entire value chain from an environmental, safety and economic perspective.

Specifically, the researchers explored two variations of the bacteria-based process. The first one uses fermentation and reactive extraction, while the other uses fermentation and electrodialysis. Both technologies have inherent hazards and require the right measures to enhance process safety and mitigate environmental loads and worker exposure.

The collaboration successfully designed and analyzed process for bio-succinic acid as a “truly green pharmaceutical” from abandoned wood waste. The method proved to have 28% less environmental impact and a 39% higher estimated profit compared to standard succinic acid produced from crude oil, as is done currently.

The authors state that their work “emphasises the importance and potential to combine metabolic engineering, advanced process modelling and sustainability assessment for the development of optimal, integrated biomass-based production.”

This work involved a collaboration between EPFL’s Institute of Chemical Sciences and Engineering, Chalmer’s University and ETH Zurich. It was funded by the Swiss National Science Foundation.

Reference

Morales M, Ataman M, Badr S, Linster S, Kourlimpinis I, Papadokonstantakis S, Hatzimanikatis V, Hungerbühler K. Sustainability Assessment of Succinic Acid Production Technologies from Biomass using Metabolic Engineering. Energy & Environmental Science 24 March 2016. DOI: 10.1039/C6EE00634E