A Fast Track From Algae Biomass to Biogas

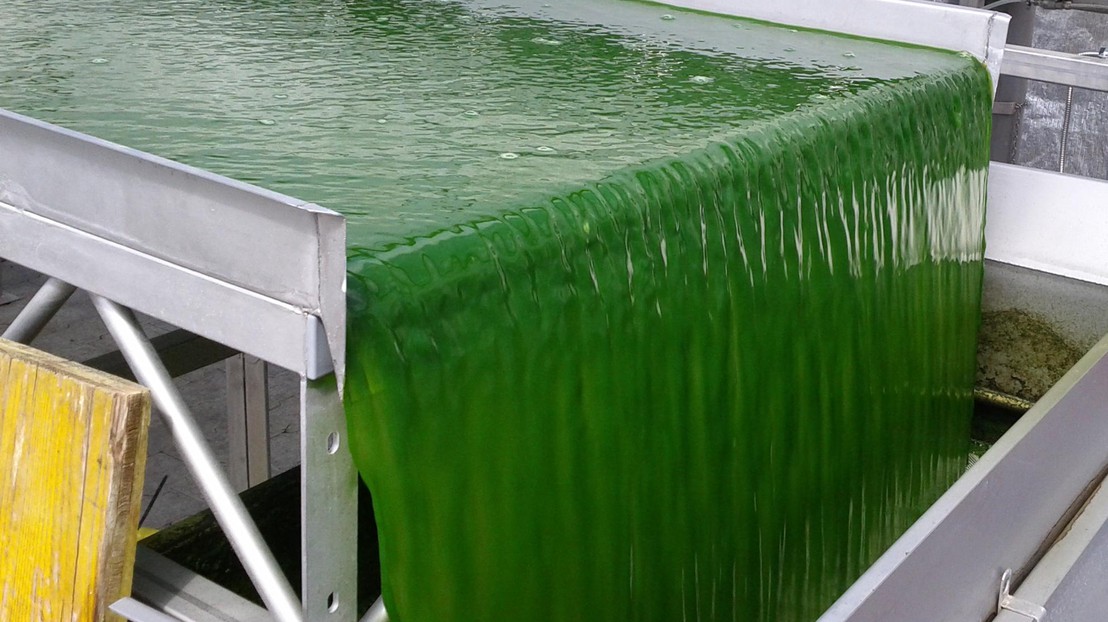

© Applied Science University of Zurich ZHAW – Dominik Refardt, 2013

Could microalgae fuel the future? Researchers are fine-tuning a technology that transforms wet algal biomass into a biogas that is compatible with today’s natural gas infrastructure.

Microalgae derived biogas is becoming an increasingly promising alternative to fossil fuels. Over the past years, researchers at the Paul Scherrer Institute (PSI) and EPFL have been developing SunCHem, a resource and energy efficient process, to cultivate microalgae and convert them into synthetic natural gas, a biofuel that is fully compatible with today’s expanding gas grid. In an article published in late January 2014, they present one of the first continuous biomass to biogas conversion technologies. The article appeared online in the journal Catalysis Today.

While it takes nature millions of years to transform biomass into natural gas, it takes the SunCHem process less than an hour to produce biogas. The secret behind this feat is a process called hydrothermal gasification. First, algae-rich water is heated under pressure to a supercritical liquid state, to almost 400 degrees Celsius. In this supercritical state, the water effectively dissolves the organic matter contained in the biomass, while inorganic salts become less soluble and can be recovered as a nutrient concentrate. By gasifying the remaining solution in the presence of a catalyst, it is then split into water, CO2, and the methane rich biogas.

Although the approach is still about five to seven times too expensive to compete with natural gas, microalgae evade much of the criticism that other biofuel sources face. They can be grown in raceway ponds built on non-arable land, without competing with agricultural food production. And although the algae need water to grow in, they are not picky. Depending on the species, they can grow in freshwater or saltwater, and in the future, they could potentially even be used to treat wastewater. A study published last year estimated that, for each unit of energy spent to produce the biogas, between 1.8 and most optimistically 5.8 units of energy could be produced.

To save resources, cut costs, and increase the overall efficiency of the process, the entire system can be run in a closed loop. “Some nutrients such as phosphate are limited resources, which we can recover when we gasify the biomass. Feeding them back into the water that we grow the algae in has a spectacular effect on their growth,” says Mariluz Bagnoud, one of the two lead authors of the publication.

For the publication, the researchers proved the feasibility of running the system as a continuous process. But they also found that feeding back water and nutrients over long durations leads to a degradation of the system’s performance. “We detected the deactivation of the catalyst used in the gasification process and we expect the accumulation of trace amounts of aluminum,” says Bagnoud. “The toxicity of the aluminum on the microalgae depends on the pH. By cultivating the algae at a neutral pH, these toxic effects can essentially be eliminated,” she says. “Now, the next steps will involve fine-tuning the process to increase the longevity of the catalyst, which is deactivated by the sulfur contained in the microalgae,” she concludes.

Reference:

Mariluz Bagnoud-Velásquez, Martin Brandenberger, Frédéric Vogel, Christian Ludwig; Continuous catalytic hydrothermal gasification of algal biomass and case study on toxicity of aluminum as a step toward effluents recycling; Catalysis Today, Volume 223, 15 March 2014